- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting machines

Results for

Cutting machines - Import export

DOREY

France

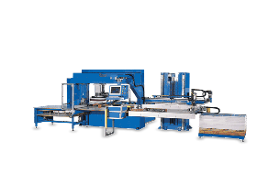

The Die Cutting machine type EDP-W represents the highest automated system to cut various types of materials into the desired shapes. Feeding of material is automatic and managed by a transportation conveyor running together with a beam holder. Machine power permits to cut shapes of various sizes. From light to heavy materials and of different thicknesses could be processed. EDP-W has a wide range of configurable cutting forces and cutting head surface.

Request for a quote

DOREY

France

The Die Cutting machine type EDP-N represents the highest automated system to cut various types of materials into the desired shapes. Feeding of material is automatic and managed by a double set of motorized conveyor belts. Machine power permits to cut shapes of various sizes. Supported materials range from light to heavy; different thicknesses can be processed. Depending on the material, more layers can be cut at the same time.

Request for a quote

DOREY

France

Ultrasonic welding machines of the Seamsonic series combine all the physical advantages of ultrasonic welding with the whole range of technological sewing experience. On the PFAFF 8301/8310/8312 Seamsonic the workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid changing pressure vibrations. The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld.

Request for a quote

DOREY

France

With the new 8311, PFAFF INDUSTRIAL introduces a new generation of ultrasonic welding machines. With more than 30 years experience in rotary ultrasonic welding, the engineers at PFAFF have successfully developed this process even further. In addition to the regulation of speed and welding energy, the new 8311 allows the force measured during welding to be measured and kept constant - a true world first and a quantum leap in textile ultrasonic welding. Adjusting and handling the machine becomes much easier. The process becomes clearer, more reproducible and easier to understand. In short, the machine is taken to a new level.

Request for a quote

DOREY

France

Ultrasonic welding machines of the Seamsonic series combine all the physical advantages of ultrasonic welding with the whole range of technological sewing experience. On the PFAFF 8310 the workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid changing pressure vibrations. The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld. Ultrasonic welding with the Seamsonic is a modern, innovative and economic alternative and complementary to conventional sewing technology. If assembling of laminates, clothing fabrics with high share of polymer and technical nonwovens is required and in particular to get, the use of the Seamsonic is the first choice.

Request for a quote

DOREY

France

The flat-bed, die cutting machine for kiss cutting type NE-FB is designed to process flexible materials such as foams, plastic films, laminated materials, etc.

Request for a quote

DOREY

France

The Die Cutting machine type EDP-C represents, in a compact size, the highest automated system to cut various types of materials into the desired shapes. Feeding of material is automatic and managed by a transportation conveyor running together with a beam holder. Machine power permits to cut shapes of various sizes. From light to heavy materials and of different thicknesses could be processed. EDP-C has a wide range of configurable cutting forces and cutting head surface.

Request for a quote

DOREY

France

The usable cutting area is available in multiple sizes allowing to process small to extra-large fabrics rolls. The SM-332-TA reaches speeds of up to 90 m/min with an acceleration of 1G with a motion repeatability +/- 0,1 mm. The cutting area is sectioned to concentrate the vacuum power in specific areas. Pressure bar and side grippers for synchronized movement of the conveyor with the fabric. Motorized conveyor belt to maximize cutting accuracy on long lengths. The SM-332-TA can be equipped with an optional motorized unwind system for large rolls with automatic material alignment control and correction and a digital tension control system.

Request for a quote

DOREY

France

The Flexa automatic roll slitter is robust and designed to meet high-volume production requirements. It can slit rolls of different sizes into narrower rolls. Intelligent remote service: The Stratos 170 can be connected to the Internet for remote assistance, for fast, efficient diagnostics.

Request for a quote

DOREY

France

The PFAFF 8301 uniquely combines all the physical advantages of ultrasonic welding with the whole range of technological sewing experience. On the PFAFF 8301 the workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid chan- ging pressure vibrations. The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld.

Request for a quote

DOREY

France

The LM-WR laminating machine is designed to laminate flexible materials like: foam materials, textile, rubber and plastic filmes with single or double-sided adhesive tapes. Multiple layers processing is as well possible. The machine can be configured with single or multiple unwinders, liner removal, slitter system, cross cutter, winders and tables for sheet format handling.

Request for a quote

DOREY

France

The preparation of tapes before lamination is often an important step in terms productivity. The new GCM works directly from overlays coils thickness from 0.04 to 0.4 mm with or without magnetic tape. Depending on the machine configuration, the hourly rate reaches 1200 format welded, cut to length and stacked. Benefits Fully automatic suction cup brings a destacker hearts in the process, capacity of 1000 sheets 0.7 mm thick. Cleaning sheets before being fed into the machine, each sheet passes PVC or PET in a special cleaning roller. You do not have to worry about the cleanliness of the cards before lamination. High technology, high precision alignment and positioning hearts compared with magnetic tapes. Depending on the heat size, the magnetic strip can be positioned much higher than the overlay on the bottom. In the assembly process, a special ultrasonic welding of two or three layers fixed with accuracy.

Request for a quote

DOREY

France

Removing the roller tracks by independent heating up to 220 ° C Adjustable speed of laying tracks up to 5 m / min Manual loading of sheets Side guides adjustable micrometer Winding device holder with the magnetic track detection cell in case of breakage. Mounting Tape with voltage control, and adjustable positioning guides the rollers. Positioning + or 0.1 mm servo motor 0,75 KW Cleaning system with a double face support roller on the output Storage formats tracked on a table with two anti static positioned before the guillotine and before the table Touch screen control friendly, multi lingual (French and / or English), setting and trimming various counts Use of electrical, hydraulic and pneumatic standardized Safety guards for strict compliance with CE OPTIONS MTL 700 NSA automatic loading of sheets Roller and additional heating system for a different bandwidth

Request for a quote

DOREY

France

CAR series are designed for cutting and selective cutting total a wide variety of products requiring high accuracy positioning in the cup. Suitable materials paper, aluminum sheet, copper foil, rubber, polymer, paper AL laminated plastic such as PP / LCD / PC / PET / PVC static or anti static materials such as foam made ​​of PU / PE / EPE / EVA etc felt. For printed products blank as a printed mark using optical fiber serving as a sensor or CCD camera. Ideal for labels, printed stickers, plates nominal labels for bar code stickers and tags and rigid. Products for smooth precise cutting and high speed insulating products adhesived, capsules, PP liners, seals and packaging products. BENEFITS A combination of a large volume of production, precise cutting punches with a perfect cut and outer edges. Superb quality of the cut, due to the performance of the tool die punch, the punch mounted on wood that are compatible and interchangeable.

Request for a quote

DOREY

France

Extraction of individual cards from two removable loading magazines The timing belt transporting system moves the cards from one workstation to another in a synchronizes manner Card thicjness measuring station ensuring only one card is fed CNC cavity high speed milling head for up to 60,000 RPM and dust extraction Hot melt tape spoller, puncher, laminating and peel off system to laminate with chip module tape Chip module punching station and pick & places system for chip module implanting in the cavities Bonding on chip into the card cavity Cooling press qtation Data input device Sorting of cards into good and reject magazines PC based control for easy operation Production capacity of up to 3,000 cards per hour Smooth, low impact operation reduces the noise level of hot melt adhesive Modular design Integrated hot melt lamination system Very stable ans consistent production process

Request for a quote

DOREY

France

The machine is fully automatic punching and stacking system for GSM cards (Global System for Mobile Communications). It is designed to punch the Subscriber Identity Module (SIM) and scribe a break out line according to the GSM 11.11 standard. BENEFITS Extraction of Individual cards from two removable loading magazines. The timing belt transporting system moves the cards from one workstation to another in a synchronized manner. SIM punching operation is driven by hydraulic system. Scribing of break out lines with pneumatic driven tool knife edge. Removal of waste material into an external container. Automatic stacking of the finished cards in two output removable magazines. Complete CE safety guards. The touch screen monitor makes the machine easy to operate and self diagnostic trouble shooting makes the machine user friendly.

Request for a quote

DOREY

France

Automatic Feeder approximately 1000 sheets per suckers Anti static bar and double sheet detection Gripping and transferring the sheets entering the air bag assembly is driven by a servomotor and ball screw to ensure accuracy in the positioning + 0.1 mm Mark detection for automatic alignment of the sheet by XY two high precision optical lasers + 0.1 mm Detecting printed marks on the Y axis by one laser precision optical alignment and automatic + 0.1 mm positioned at the inlet of the tool Tool punch die cavities horizontal or vertical SYSCO manufacturing Hydraulic quick and silent 5 Tons Stacking cards interchangeable with 6 stores Transferring sheets in output controlled by servomotor and ball screw Evacuation from falling rollers

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOREY

France

Auto cutting of plastic ISO cards from sheets of stacked and printed material. Available for any commercial sheet format. FEATURES A combination of high volume production, accurate die cutting, and high quality card edges Inboard & outboard ball screw servo driven gripper unit with position accuracy of +/ 0.1mm The shear type male & female die ensures excellent clean cut edges The optical sensors with registration mark tracking system ensure a cut to print accuracy of +/ 0.1mm A card stacking unit with 2 interchangeable magazines, each holding up to 450 cards with a thickness of 0.8mm Scrap web is automatically discharged The touch screen monitor makes the machine easy to operate Complete CE safety guards An air flotation system protects the cards from scratching during the feeding process An auto sheet feeder with trolley holds approximately 1 000 sheets, with a sheet thickness of 0.8mm Special accessories are available for thze accurate punching of contact less plastic cards

Request for a quote

DOREY

France

The T.T. E digt is an electro pneumatic cutting machine with small dimensions also suitable for installation in places with limited space such as workshops. The electricity supply at 230V single phase and the low consumption of compressed air contribute to a still more easy to install. The sectors of use are varied textile, leather, footwear, etc. wherever you need to cut materials length as rubber bands, ribbons, laces, drawstrings, zippers, velcro, straps, shoulder straps, mignon, belts. Depending on the machine configuration, it can cut By cold with scissors blades made of tempered steel and self sharpening cutting light with a maximum of 120 mm; By heat with a heated knife by low voltage electrical resistance, the cutting takes place by thermal fusion (only suitable for synthetic materials) with a 110 mm cutting light and can be equipped with an automatic device for inclined cut; By cold and heat, used separately, directly selectable from the electronic programmer.

Request for a quote

DOREY

France

- Unique control software for complete integration, fast communication between work areas and synchronized positioning accuracy down to a few micrometers for the most complex, high-value-added products. - Servomotor-controlled upper and lower unwind/rewind. - Cutting speed up to a maximum of 56 m/minute. - Laser integration on request, or for specific product requirements that cannot be met by conventional tools. - Closed-loop tension management with integrated sensors on all our unwinders/rewinders. - Configurable from 3 stations; widths from 10″ (250 mm) to 30″ 750 mm. - Stations equipped with independently controlled servomotors, strictest tolerances in the industry. - Operator console with touch-screen option. - Material savings with label mode. - CCD cameras Dedicated to processes fully integrated with our control software. - CE quality.

Request for a quote

DOREY

France

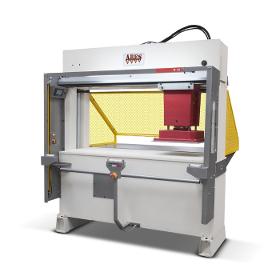

Four columns press with mechanical balancing system SYSCO exclusive Cutting power from 30 to 400 Tons Cutting area from 900 x 600 to 2500 x 1200 mm Cutting stroke from 110 to 250 mm 4 manual or motorised mechanical stops accuracy +/ 0.01 mm Trough cutting or kiss cutting on Picard steel plate 60 HRC accuracy +/ 0.01 mm Slow down speed of the bridge 10 mm before touching the material Quick change of dies Touch screen control in different languages Use of electrical, hydraulic and pneumatic standardized Safety guards protection and / or photocells Class 4 Meets C.E. standards

Request for a quote

DOREY

France

ANY TYPE LARGE SIZE ENVELOPE CLOSE DIE CUTTING FOUR CORNER CUTTING FOR POCKET TYPE AND WALLET TYPE ENVELOPES GENERAL DESCRIPTION Head driven by double chain with frequency converter cushion system to stop at one cutting position with position accuracy ±0.2mm Working capacity up to 400,000 blanks per 8 hours with maximum material stack thickness up to 60mm Die lubrication for clean cuts and longer die life Cutting pad shifter extends pad life Optional adjustable die holder allows for cutting many different sizes of envelope with the same four corner dies, thus saving the cost of expensive dies Maximum blank size 480×550mm (THNC N25) / 600×600mm (THNC N30) Optional pneumatic head center ejector ensures maximum cutting size accuracy for stack material Optional four corner dies Optional front and rear waste removal conveyor belts

Request for a quote

DOREY

France

An integrated servo cutting machine with high accuracy and high productivity. The HHC series servo cutting machine is specially designed for die cutting the products with low noise, low vibration, high accuracy and high productivity. HHC series is suitable for multi layer roll form laminated soft material and less than 0.3mm thick rigid metal film materials. HHC SERIES ARE DESIGNED FOR VARIOUS INDUSTRIES CONVERTING APPLICATIONS RFID smart label, printed label sticker, electronic components, LCD films, medical components, automotive products, name plate, gasket, insulation foam

Request for a quote

DOREY

France

Three sets of servo motor position systems, position accuracy +/ 0.2mm. Working capacity up to 57 600 pieces of abrasive disc per 8 hours with two cavity cutting die to cut two plies of roll material. User friendly computer control and 100 cutting program memory provides easy operation. Punch slugs go through punch tube to slug box under head and you can use a vacuum cleaner to clear out the slugs. Cut part auto knock out & stacking system will stack cut parts to preset quantity ready to be packed. This function can save several workers. Auto cutting directly from jumbo rolls can not only simplify manufacturing process, but also achieve material savings up to 15%. Unique stainless steel grid plate feeding device & stacking system can achieve perfect feeding & stacking results for all kinds of non woven felt, Velcro backing

Request for a quote

DOREY

France

CLICKING PRESS WITH MOTORISED ROTATING ARM The new series of F-R punching machines with motorised rotary arm is available both in EC as well as not EC versions at truly competitive prices, with the ad- vantage of less taxing usage for operator, and consequential positive effects for company production. The version for countries subjected to EU standards is supplied with a series of external protection devices, photo electrical protection barriers and an electrical system including various safety devices and lateral tables. For the not EC version, external protection devices with or without photo electrical barriers are supplied upon request, in this case two practical lateral tables are supplied. Light bulb and stroke counter (additional or programmable type) are available upon request for both version.

Request for a quote

DOREY

France

The clicking press ARES combine the best that oleodinamic and electronics can offer in the field of clicking presses. The main features which make them clearly in quality are the following: STURDINESS: the triangular structure of the base with double ribbing and the column of the arm uprated remove bending and ensure great efficency and precision in cutting CONSTRUCTIVE TECHNICS: the lack of rubber packings guarantees an unlimited life to the cylinder elements. The electro-distributor is controlled by a programmed card relized with the most electronic elements with integrated circuits and allows a rapid and silent work

Request for a quote

DOREY

France

Elettric Travelling Head cutting press 25 -30 Ton Most technologically advanced model available on the market of its kind – Fully electric without oil gaskets, pump, motor, flywheel etc – Reduced periodic maintenance that facilitates after sales assistance, remote control and remote assistance – Green production system that respects the environment with low co2 emission -Totally innovative with electric consumption less than 75% lower than a traditional hydraulic die cutter – Sound emission during the operating phase equal to 0 decibels and limited only in the fraction of a second during the cutting phase -Versions available with industry 4.0 preparation

Request for a quote

DOREY

France

Double automatic end of stroke adjustment in order to use different height knives without any setting-up, or electrical end of stroke. Timed adjustable cutting plate upstroke. Adjustable travelling head return. Photoelectric cell protection for traverse and cutting. With cont rol buttons for free access to the work table.

Request for a quoteResults for

Cutting machines - Import exportNumber of results

29 ProductsCountries

Company type