- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting

Results for

Cutting - Import export

DOREY

France

The flat-bed, die cutting machine for kiss cutting type NE-FB is designed to process flexible materials such as foams, plastic films, laminated materials, etc.

Request for a quote

DOREY

France

The usable cutting area is available in multiple sizes allowing to process small to extra-large fabrics rolls. The SM-332-TA reaches speeds of up to 90 m/min with an acceleration of 1G with a motion repeatability +/- 0,1 mm. The cutting area is sectioned to concentrate the vacuum power in specific areas. Pressure bar and side grippers for synchronized movement of the conveyor with the fabric. Motorized conveyor belt to maximize cutting accuracy on long lengths. The SM-332-TA can be equipped with an optional motorized unwind system for large rolls with automatic material alignment control and correction and a digital tension control system.

Request for a quote

DOREY

France

The LM-WR laminating machine is designed to laminate flexible materials like: foam materials, textile, rubber and plastic filmes with single or double-sided adhesive tapes. Multiple layers processing is as well possible. The machine can be configured with single or multiple unwinders, liner removal, slitter system, cross cutter, winders and tables for sheet format handling.

Request for a quote

DOREY

France

The Die Cutting machine type EDP-N represents the highest automated system to cut various types of materials into the desired shapes. Feeding of material is automatic and managed by a double set of motorized conveyor belts. Machine power permits to cut shapes of various sizes. Supported materials range from light to heavy; different thicknesses can be processed. Depending on the material, more layers can be cut at the same time.

Request for a quote

STEEC

France

STEEC has been a pioneering company in cutting and laser micro-cutting in France. Since the first YAG industrial laser in France was installed in the premises of the company in 1983. 30 years ago STEEC developed unique know-how and competence in this field which it offers its customers as part of its subcontracting service. The company now has 5 laser cutting machines which enable it to meet a wide range of requirements. These machines, in which the company continually investing, have been custom designed according to STEEC specification in order to comply with the quality and precision standards demanded by the customers. Using its highly efficient innovating machines STEEC carries out very high precision cutting on flat and tubular parts with thickness ranging from 3mm to 2µm !

Request for a quote

GRAVOTECH

France

SINGLE WORK ENVIRONMENT The LS100 desktop laser engraver is a premium solution. It is the only gantry laser etching machine on the market made of one-piece aluminium chassis, that includes multi-technology, professional CAD/CAM software and an RF laser source. THE SWISS ARMY KNIFE OF LASER ENGRAVERS LS100 is a silent desktop laser engraver adapted for industrial, commercial and office settings. Engrave glass, create plastic labels, shape acrylic, wood, cut, mark, and define folding lines on paper: this CO2 laser will suit your every need. EASY WORKFLOW One by one or by batches, the LS100 CO2 laser cutter and engraver improves your productivity thanks to time-savings features: automatic touch sensing, embedded control dashboard and backlit marking or cutting table with a wide front-loading door.

Request for a quote

GRAVOTECH

France

LARGE LASER ENGRAVING MACHINE The unique engraving surface that allows you to take advantage of the 9.84 in height z-axis making bulky objects easier. The working space becomes easier thanks to the pass-through, the smallest machine on the market to feature this, making this ideal for individual projects and even small batch work, with most objects able to fit. FAST LASER ENGRAVER AND LASER CUTTER Taking advantage of our history with industrial laser engravers we bring that technology to you with the LS900 CO2 laser engraver up to 4m/sec which makes it an asset to improve your productivity. With a choice between step motors or brushless motor, you can find a tailored solution for your projects and needs, keeping productivity at the forefront of your workflow. UNLIMITED POSSIBILITIES Mark and cut anything with your choice of laser source, the Fiber laser machine for metals, CO2 laser engraver for organics and minerals, or Edge combining a Fiber laser machine and CO2 laser engraver.

Request for a quote

GRAVOTECH

France

HIGH-PERFORMANCE Developed from a monobloc structure the ISx000 CNC engraving machine range is a solid workhorse. A choice between 4 high frequency motors means that you will be working with the highest performance whichever the material and its thickness. VALUE FOR MONEY These CNC engraving machines make high volume jobs quicker and easier. The ISx000 CNC routers range remains unrivalled on the ratio, price per working area, on the market. Once you have set up the job on Gravostyle, you can trust the milling machine to do the task in all safety without your constant supervision. ADAPTABLE 3 different sizes, 2 motorized axis (stepper or brushless motors) and a wide range of accessories. Light and deep engraving, batch labelling, drilling, and 2.5D milling (hot iron) the ISx000 CNC engraving machines are versatile enough to be used in most industrial applications.

Request for a quote

LOUISON INDUSTRIES

France

Industrial fabric cutting process Louison Industries offers custom cutting and cutting of textile fabrics produced by us. We offer made-to-measure industrial textile cutting for a wide variety of textiles. Whether for composite materials, reinforced technical fabrics or special textiles, our tailor-made approach guarantees professional-quality results that perfectly meet the specific needs of each project. Our industrial textile cutting skills encompass three main techniques: - Hot cutting - Cold cutting - Ultrasonic cutting We can produce a professional quality cut, adapted to the composition of the chosen textile, for all materials, small and large widths, from 10 to 1600 mm. The idea is to provide you with a finished product that can be used straight away.

Request for a quote

DOREY

France

Auto cutting of plastic ISO cards from sheets of stacked and printed material. Available for any commercial sheet format. FEATURES A combination of high volume production, accurate die cutting, and high quality card edges Inboard & outboard ball screw servo driven gripper unit with position accuracy of +/ 0.1mm The shear type male & female die ensures excellent clean cut edges The optical sensors with registration mark tracking system ensure a cut to print accuracy of +/ 0.1mm A card stacking unit with 2 interchangeable magazines, each holding up to 450 cards with a thickness of 0.8mm Scrap web is automatically discharged The touch screen monitor makes the machine easy to operate Complete CE safety guards An air flotation system protects the cards from scratching during the feeding process An auto sheet feeder with trolley holds approximately 1 000 sheets, with a sheet thickness of 0.8mm Special accessories are available for thze accurate punching of contact less plastic cards

Request for a quote

DOREY

France

The T.T. E digt is an electro pneumatic cutting machine with small dimensions also suitable for installation in places with limited space such as workshops. The electricity supply at 230V single phase and the low consumption of compressed air contribute to a still more easy to install. The sectors of use are varied textile, leather, footwear, etc. wherever you need to cut materials length as rubber bands, ribbons, laces, drawstrings, zippers, velcro, straps, shoulder straps, mignon, belts. Depending on the machine configuration, it can cut By cold with scissors blades made of tempered steel and self sharpening cutting light with a maximum of 120 mm; By heat with a heated knife by low voltage electrical resistance, the cutting takes place by thermal fusion (only suitable for synthetic materials) with a 110 mm cutting light and can be equipped with an automatic device for inclined cut; By cold and heat, used separately, directly selectable from the electronic programmer.

Request for a quote

DOREY

France

- Unique control software for complete integration, fast communication between work areas and synchronized positioning accuracy down to a few micrometers for the most complex, high-value-added products. - Servomotor-controlled upper and lower unwind/rewind. - Cutting speed up to a maximum of 56 m/minute. - Laser integration on request, or for specific product requirements that cannot be met by conventional tools. - Closed-loop tension management with integrated sensors on all our unwinders/rewinders. - Configurable from 3 stations; widths from 10″ (250 mm) to 30″ 750 mm. - Stations equipped with independently controlled servomotors, strictest tolerances in the industry. - Operator console with touch-screen option. - Material savings with label mode. - CCD cameras Dedicated to processes fully integrated with our control software. - CE quality.

Request for a quote

DOREY

France

ANY TYPE LARGE SIZE ENVELOPE CLOSE DIE CUTTING FOUR CORNER CUTTING FOR POCKET TYPE AND WALLET TYPE ENVELOPES GENERAL DESCRIPTION Head driven by double chain with frequency converter cushion system to stop at one cutting position with position accuracy ±0.2mm Working capacity up to 400,000 blanks per 8 hours with maximum material stack thickness up to 60mm Die lubrication for clean cuts and longer die life Cutting pad shifter extends pad life Optional adjustable die holder allows for cutting many different sizes of envelope with the same four corner dies, thus saving the cost of expensive dies Maximum blank size 480×550mm (THNC N25) / 600×600mm (THNC N30) Optional pneumatic head center ejector ensures maximum cutting size accuracy for stack material Optional four corner dies Optional front and rear waste removal conveyor belts

Request for a quote

DOREY

France

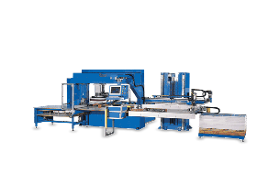

An integrated servo cutting machine with high accuracy and high productivity. The HHC series servo cutting machine is specially designed for die cutting the products with low noise, low vibration, high accuracy and high productivity. HHC series is suitable for multi layer roll form laminated soft material and less than 0.3mm thick rigid metal film materials. HHC SERIES ARE DESIGNED FOR VARIOUS INDUSTRIES CONVERTING APPLICATIONS RFID smart label, printed label sticker, electronic components, LCD films, medical components, automotive products, name plate, gasket, insulation foam

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOREY

France

Material feeding from sheets or rolls. Pneumatic clamping beam feed with side guides to work several layers of materials without slipping. Cutting power from 25 to 100 tons. Fast and silent Hydraulic pump up to 80 cuts/min, air cooling. Cutting area from 2100 x 500 to 2500 x 1200mm. Cutting head from 500 x 500 mm to 900 x 900 mm, adjustable stroke up to 130 mm or 180 special version. NYLON Cutting Belt. The travelling head movement is controled by servomotor and ball screw (2nd axis) with an accuracy of + or 0.2 mm. 4 motorized adjustable mechanical stops ensure precise cutting depth accuracy + / 0.02 mm and thus prolong the life of the belt or pad. Use of standard electrical, hydraulic and pneumatic parts. Safety guards with Plexi windows connected to the system shutdown and / or photocells Class 4 for strict compliance with CE Available Options head rotation 360 °, the 3rd axis of the CNC. Automatic nesting SYSNEST software saves

Request for a quote

DOREY

France

AUTOMATED PRODUCTION OF RETRACTABLE INSECT SCREENS First introduced in 2005, machines of the 520 series caused a revolution in the insect screen industry by drastically reducing the production time needed to make a screen, the necessary man power, and the discards. With its wide variety of tools, accessories and software solutions, this machine is, by far, the most complete manufacturing solution for quality 6 meter profiles and custom sized retractable insect screens solutions available on the market today and will deliver the efficiency and quality that you are looking for. With more than 150 units supplied to major manufacturers of insect screens in Europe and beyond, machines of the 520 series have proven their worth and reliability throughout the years and are a benchmark in the industry.

Request for a quote

DOREY

France

From the innovators of welding automation, Miller Weldmaster presents the AES1800. Designed to automatically finish your rolled products, the AES1800 will weld, grommet and cut your products to eliminate excessive labor. The bottleneck of your workflow no longer has to be your finishing operation. The AES1800 is equipped with sensing cameras to ensure your grommets and cuts happen at the specific spot you determine. From preprinted banners to tennis court shading, the AES1800 will dramatically increase your products and reduce your labor needs. FEATURES, FUNCTIONS, & BENEFITS Throat capacity available in 1.21M or 1.82M (4ft or 6ft) Controlled through Miller Weldmaster Smart Screen PLC Fabric Unwind Stand Assembly Linear actuation for edge guiding Driven Fabric Puller Accumulating System Camera sensor for image sensing Digital footage counter Fabric cutting unit

Request for a quote

INOVER SARL

France

More than 30 years of experience in producing special carbide cutting tools, our professional team are ready to help you to solve the cutting tools problems.

Request for a quoteResults for

Cutting - Import exportNumber of results

22 ProductsCountries