- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding

Results for

Grinding - Import export

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 2002 CNC control : FANUC 160i-M Stroke X axis : 1300 mm Max. Stroke speed X axis : 1800 mm/min Rapid traverse rate X axis : 4000 mm/min Stroke Y axis : 800 mm Max. Stroke speed Y axis : 1800 mm/min Rapid traverse rate Y axis : 4000 mm/min Stroke Z axis : 170 mm Min. Stroke speed Z axis : 0.500 mm/min Max. Stroke speed Z axis : 14000 mm/min Stroke frequency Z axis : max. 5 Hz Stroke W axis : 635 mm Rapid traverse rate W axis : 1150 mm/min Planetary speed C axis : 5 - 300 rpm Stroke U axis (radial feed) : 5.5 mm Distance between columns : 970 mm Table length : 1440 mm Table width : 860 mm Max. distance spindle nose / table : 750 mm Max. load on table : 800 Kg With equipment

Request for a quote

LBI

France

We manufacture rough or fully machined segment liners for grinding mills in 15% leaded bronze

Request for a quote

MARTEAU & LEMARIE

France

Grinding/Polishing balls and glass beads are mainly stored in steel, stainless steel and glass. Contrary to precision balls sold per unit, these grinding/polishing balls and glass beads are sold per kilo.

Request for a quote

KRAFFTER MACHINE TOOLS

France

x1 infeed Z-axis: Infeed operation, metric 4 E-M with position reading - ref: 111-2-10666 x1 cross feed X-axis Fine cross feed 4 FQ-M - ref: 111-2-21708 x1 grinding stroke 3H: operation of the grinding stroke either by lever or by hand wheel - ref: 111-2-15167 (WS11) x1 grinding spindle Q 36-12, complete 9 JKP x1 workhead spindle BP 60-25 with W25 collet reception x1 dust extraction unit x1 foot switch 9 M - operation of infeed Z-axis by foot pedal. Infeed stroke sleeplessly adjustable - ref: 111-2-15740 x1 LED machine lamp 24V/2.6W x1 digital display 4DZ + X +Y-MZ + digital indications for axes Z, X and Y - ref: 111-2-47178 x1 ISOMA microscope - optic from the front x1 ISOMA microscope - optic from the top x1 radius grinding attachment 25ABP - ref: 111-2-23294 x1 dividing head TS20 (6°) for radius grinding attachment 20ABP/25ABP - ref: 111-2-42192 x1 Touch-Test TT acoustic touch control (grinding wheel to workpiece) - ref: 56-4050 x1 Headset TT-K Stereo - ref: 56-4755

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing :2004 CNC control: FANUC 180i-MB Stroke X axis: 500 [mm] Min. Stroke speed X axis: 0.0001 [mm/min] Max. Stroke speed X axis: 2000 [mm/min] Stroke Y axis: 300 [mm] Min. Stroke speed Y axis: 0.0001 [mm/min] Max. Stroke speed Y axis: 2000 [mm/min] Stroke Z axis: 140 [mm] Min. Stroke speed Z axis: 0.0001 [mm/min] Max. Stroke speed Z axis: 2000 [mm/min] Stroke W axis: 350 [mm] Planetary speed C axis: 1 - 300 [rpm] C axis max. speed: 20 [rpm] Max. Stroke speed W axis: 2000 [mm/min] Stroke U axis (radial feed): 11 [mm] Table length: 610 [mm] Table width: 305 [mm] Supply voltage: 400 [V] ADDITIONAL INFORMATION: x1 spindle DÄNZER DHB 0911.000 WW x1 oil cooler TURMOIL model OCO-33 RO x1 mist extraction unit FILTERMIST model F600 x1 MOORE Autosize tool edge probe x1 MOORE TOOL automatic wheel dresser x16 tool holders x1 RENISHAW OMP 40 workpiece probe x1 MOORE TOOL clamping box Full technical documentation

Request for a quote

KRAFFTER MACHINE TOOLS

France

Stroke X axis: 650 mm Max. Stroke speed X axis: 4000 mm/min Working feed X axis: 0 - 1800 mm/min Stroke Y axis: 450 mm Working feed Y axis: 0 - 1800 mm/min Stroke Z axis: 130 mm Min. Stroke speed Z axis: 0.5 mm/min Max. Stroke speed Z axis: 12000 mm/min Stroke frequency Z axis: max. 4 Hz Stroke W axis: 500 mm Planetary speed C axis: 5 - 250 rpm Max. Stroke speed W axis: 800 mm/min Stroke U axis (radial feed): 5.5 mm Distance between columns: 750 mm Table length: 770 mm Table width: 630 mm Clearance between grinding motor and table: 585 mm Max. load on table: 500 Kg Supply voltage: 400 V Weight: 4550 Kg EQUIPMENT INCLUDED: x1 HI-CUT pack including: -work area protection -exhaust system with electrostatic air filter -fire protection system (to be assessed by a qualified body) -automatic paper tape filtration unit x1 grinding motor x1 cable for grinding motor Machine visible under power in our premises by appointment.

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing :2016 CNC control: FANUC 31i Software installed: Quinto 5.4.6 Number of axes: 5 Stroke X axis: 470 [mm] Max. Stroke speed X axis: 20000 [mm/min] Stroke Y axis: 390 [mm] Max. Stroke speed Y axis: 20000 [mm/min] Stroke Z axis: 325 [mm] Max. Stroke speed Z axis: 10000 [mm/min] Table length: 1000 [mm] Table width: 275 [mm] Grinding wheel speed: 12000 [rpm] Grinding spindle motor power: 10 [kW] Internal workpiece spindle nose: HSK 50 Dimension:s 2600 x 3500 x 2600 [mm] Weight: 4700 [Kg] Machine visible under power in our premises by appointment. Price on request, loading on truck included. Possibility of shipping Worldwide.

Request for a quote

LBI

France

We manufacture rough or fully machined bushing for gyratory crushers in 15% Leaded Bronze

Request for a quote

DOREY

France

Width 100 mm Bedplate and load bearing structure with easy dismounting Support cross members Main shaft group Front and rear plate unit Feed roller unit with micrometric adjustment Main drive unit Brush and feed rollers unit driven by servomotor Grinding wheel dressing unit gr. 36 Pneumatic control panel Electrical control panel Electronic programmable logic unit using a dedicated software for total management of machine functions with dust suction device CZ Dust Collector C4 Metering device (Alarm with light to inform about maintenance periods)

Request for a quotePOUGET

France

USE : Rail Cutting, Rail Grinding, and Various Deburing Tasks. ADVANTAGES : These Disks and Grinding Wheels are both very safe and highly effective, They are compliant with European Safety Standard. IMPORTANT NOTE : In the Interest of Safety, Grinding-Wheels and Disks must be stored in a cooled and dry place. For a normal Efficiency, it is preferable to indicate the Hardness of the rail to cut. Double-Reinforced Rail Cutting Disk (100 m/Sec.) Packet of 10 External Ø (mm) Bore (mm) Thickness (mm) Reference Machine 305 22.2 3.2 6097 TR4-12 305 25.4 3.2 6096 355 22.2 4 6099 TR4-14 355 25.4 4 6098 400 25.4 4.5 6101 TR4-16 Slitting Saw (HSS Steel) External Ø (mm) Bore (mm) Thickness (mm) Reference Machine 350 42 3 6200 TR5-14 400 42 3.5 6201 TR5-16 Cup Grinding Wheels External Ø (mm) Bore (mm) Thickness Reference Machine 52 5/8'' 60 1039-F MP.10 72 5/8'' 60 1039-D MPE.10 - MP.10 - BM.100 125 5/8'' 50 1039-K MP.121 150 5/8'' 40 1039-A N1 - N12 - N.320 -MP.121 200 130 mm 60 1039-G N.

Request for a quotePOUGET

France

USE : To descale new rails before stepping-up.(scale acts an insulator). ADVANTAGES : Simple and efficient machines to remove scale (carbon deposits) Portable Machine equipped with : - 1 Sensitive Lowering Adjustment Device - 1 Folding Wheel It can be use as : RAIL HEAD SCRUBBER MACHINE Equipped with : - Metal Descaling Brush Ø 120 mm made in hardened Steel Wires - 4-stroke petrol engine 4 KW - Ref. NB-1D - Triphase 220/380 V Electric Motor - Ref. NB-1DE - Weight 54 Kg Equipped with : - Lamella Brush Ø 250 mm Rod - 4-stroke petrol engine HONDA 4 KW - Ref. NB-2D - Triphase 220/380 V Electric Motor - Ref. NB-2DE - Weight 47 Kg RAIL GRINDING MACHINE Equipped with : - Flat Grinding Wheel Ø 150 mm (other Ø on request) - 4-stroke petrol engine HONDA 4 KW - Ref. NB-1M - Triphase 220/380 V Electric Motor - Ref. NB1-ME - Weight 54 Kg

Request for a quotePOUGET

France

USE : - Grinding of Rail Corrugation - Descaling rails before stepping-up (Scale Acts as an insulator) KEY POINT : This Machine is equipped with a Plated Jewellery of pressure on ceramic abrasive Belt for more efficient Grinding of the Running Rail-Surface. CHARACTERISTICS : - HONDA 4-Stroke petrol engine - 9 HP - 1 Adjusting inclination Device - 1 Jewellery of pressure on abrasive Belt - 1 Endless Ceramic Abrasive Belt, Width 60 mm. - 2 Rolls on opposite rails - 2 Transport Wheels on side path (Carried by 1 Single Operating Agent) Net Weights : Machine 98 Kg / Transport Trolley 12 Kg OPTIONS : - Triphase 220/380 V Electric Motor- Ref. E - Guiding Ramps of 20 Rolls (for grinding Rail Corrugation) - Ref. N-16 - Lighting for Night Works - Ref. PE - Guiding Rolls Tramway - Ref. GT - Hand Extinguisher - Ref. EXT - Spart Parts : Ceramic Abrasives Belt - Ref. BAC-24

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

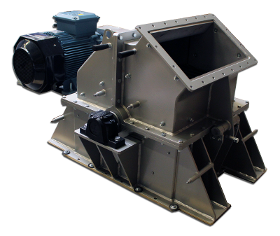

The MA (or Hammer mill) is an impact grinder that crushes the input material between the hammer (or knife) plate and a stator fitted with a sieving screen perforated for the required particle size. It is generally used as a pregrinder positioned upstream of a grinding installation. The MA breaks up blocks of raw material into smaller particles capable of being treated by a mill for fine grinding.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

POITTEMILL and FORPLEX supply complete grinding and lumpbreaking installations for the Energy and Nuclear industries. In order to respect the strict security rulings in these sectors, POITTEMILL and FORPLEX have developed confined systems which allow for easy, accessible cleaning and dismantling in all types of conditions. Close customer collaboration has led to the conception of machines that correspond precisely to the needs and expectations of the nuclear industry.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

Dryclay preparation is a key POITTEMILL process. Finegrinding stands as a landmark innovation in raw material mix preparation. The satisfaction of those adopting finegrind processing justifies POITTEMILL's development Our solution has many process advantages we can treat clay impurities totally (lime, pyrite or calcium carbonate for instance), allowing the use of raw materials previously unfit for the production of highquality finished products. The outer appearance is smoother, with a perfect skin, giving to finishes products a greater commercial value. By grinding the raw materials to an ultrafine powder, a greater homogeneity is achieved that reinforces the internal shard and mechanical strength of tiles / inner wall blocks.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

POITTEMILL designs and realizes turnkey plants involving grinding, micronization, simultaneous grindingdrying and classifying for minerals of all kinds (limestone, clay, barite, talc, coal, plaster, quartz, bentonite.....). Depending the final application we are able to purpose you the most reliable equipment for your project.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

Rotary valves have for function the distribution or the continuous dosing of pulverulent products. FORPLEX rotary valves was studied specially to be easily adapted to the base of reception hoppers, cyclones, crushers, pneumatic transport and dust removal captation devices... So they are the essential complement to any installation of grinding, pneumatic transport or classification. Using some size of rotary valves, FORPLEX can provide a solution to meet the most demanding powder properties

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The HighYield Pulverizer PHR is a mill that combines the actions of attrition, impact and shearing. It can be equipped with different rotors that accentuate the effects of attrition or impact. The design integrates easy access for maintenance and the replacement of wearing parts. The mechanical parts are situated outside of the grinding chamber to protect them from damage from high temperature drying. Different manufacturing materials are available for the wearing parts as well as ceramic materials for abrasive products that need to avoid contamination by metallic particles. The PHR provides grinding / drying operations for a feeding product of up to 85% humidity. When associated with a Dynamic classifier, very fine particle sizes can be obtained.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bed. The pendulums mounted on a star wheel are driven by a vertical shaft. Each pendulum is fitted with a grinding roller that rotates upon its axis. The rotation of the star wheel combines with the articulation of the pendulum to generate a centrifugal force at the grinding roller level. The product is ground between the grinding roller and the fixed bull ring.

Request for a quoteResults for

Grinding - Import exportNumber of results

20 ProductsCountries

Company type

Category

- Crushing and grinding machinery (10)

- Tools & Hardware (4)

- Flour milling - machinery and equipment (3)

- Grinding - machine tools (2)

- Balls (1)

- Ceramics - tiling (1)

- Industrial valves, operating equipment (1)

- Marking and labelling machinery (1)

- Moulds for glass and crystal (1)

- Nuclear power stations (1)

- Precision balls (1)