- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling and sealing

Results for

Filling and sealing - Import export

SYNERLINK

France

Our DN200 thermoforming machine is known for its very compact footprint and small budget. Its simplicity and compactness are ideal for small productions and product tests up to 5,400 cups/hour or 10,800 miniportions/hour. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions. The filling volume goes from 10 to 240 ml. Our machine can handle various materials (PS, PP, multilayer). DN200 is optimal for industries where flexibility and affordability are critical.

Request for a quote

MONGIN

France

CUTTING AFTER TUBES FILLING TYPE OF MACHINES : UNIPAC, TONAZZI, KALIX, AXIOMATIC, ... On your tube fillers lines, once tubes filled and sealed, they are cut using a knife and a counter knife. N°1 Counter knife UNIPAC N°2 Knife UNIPAC N°3 Moving blade TONAZZI N°4 Fixed knife TONAZZI N°5 AXIOMATIC cutting die

Request for a quote

SEMIN

France

COMPOSITION AND APPEARANCE Plaster-based powder coating containing calcium carbonate, resin, cellulose fibre and various additives. The mixed paste is white in colour. REFERENCE DOCUMENTS • DTU 25.41. Standard DIN 1168 • DTU 59.1: painting work • NF EN 13963 TECHNICAL CHARACTERISTICS • Granulometry: fine • Adhesion: complies with NFT 30 608 • pH: neutral APPLICATION • SEALING PLASTERBOARDS WITH ROUNDED EDGES Apply a first pass by filling the joint deeply, apply a second pass after 1 1/2 hours to smooth and finish the joint. Filling and bonding (if tape) in one pass. And finishing is possible in a single layer. • FILLING, ASSEMBLY, SEALING Dilute with 45% water. 2.2 l to 2.3 l water per 5 kg bag or 11 l to 11.5 l for 25 kg. Open bevelled cracks or rifts. Apply with a putty knife or spatula. Completely fill up the part to be filled, smooth carefully. Time of use: 45 min. Hardening: approx. 1 hour.

Request for a quote

PRO COUPE INDUSTRIES

France

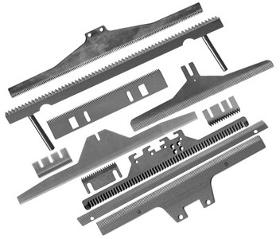

Thoothed blades for SIG® SANDIACRE® ROVEMA® FOREGROVE® PRASMATIC® OMORI® MULTIVAC® MIELE® MESOMA® MECAPACK® ILAPAK® HAYSSEN® COMMARME® BOSCH® AQUARIUS® TECNIMODERN® TETRA® TWINPACK® ULMA®

Request for a quote

SYNERLINK

France

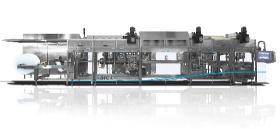

Our AR700 cup thermoforming machine is known for its user friendliness, great reliability, simple design and layout. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. Its high adaptability to changing market needs and easy operation and maintenance are ideal for high speed production lines. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed up to 57,600 cups per hour. Our machine can handle various materials (PS, PET, PLA, PP, multilayer) and deliver wide range of conical, straight and open mold cups with or without label.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SYNERLINK

France

Our DN250 cup thermoforming machine is known for its compact footprint and high cost efficiency. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed of 18,700 to 43,200 cups per hour. Our machine can handle various materials (PS, PET, PP, multilayer) and deliver wide range of conical and straight cups with or without label.

Request for a quote

SOMEFLU

France

Main applications Steel, Chemical, Mining, Environment Construction Horizontal process non-metallic pump equipped with mechanical seal Fully suitable for corrosive liquids or fluids with thick particles NP product with a recessed impeller For a free-flow version, please refere to our HV product Designing according to NFE 44121- DIN 24256 - ISO 2858 - ISO 5199 Suction and discharge line according to NFE 29-203 – DIN 2533 – ISO PN16 All hydraulic parts are machined from thick parts of plastic (no injection moulding) The shaft sealing is an own SOMEFLU cartridge mechanical seal design Cartridge mechanical seal version : standard, injection, rinsing, grease filling or double seal For ATEX (explosion proof), antistatic plastics charged with black carbon are used Materials PP, PVDF, PEHD, PE-UHMW, SOMEDUR® Performance data Max flow : 190 m³/h Max delivery head : 50m

Request for a quote

SOMEFLU

France

Horizontal process non-metallic free-flow pump equipped with mechanical seal Fully suitable for corrosive liquids or fluids with thick particles Recessed impeller with straight blades and tangential discharge section Designing according to NFE 44121- DIN 24256 - ISO 2858 - ISO 5199 Suction and discharge line according to NFE 29-203 – DIN 2533 – ISO PN16 All hydraulic parts are machined from thick parts of plastic (no injection moulding) Plastic used : PP, PVDF, PEHD The shaft sealing is an own SOMEFLU cartridge mechanical seal design Cartridge mechanical seal version : standard seal, injection, rinsing, grease filling or double seal For ATEX (explosion proof), antistatic plastics charged with black carbon are used Max flow : 180 m³/h Max delivery head : 35m

Request for a quote

SOMEFLU

France

Horizontal process non-metallic pump equipped with mechanical seal Pumps are designed for heavy-duty use in the most severe conditions Designing according to NFE 44121- DIN 24256 - ISO 2858 - ISO 5199 Suction and discharge line according to NFE 29-203 – DIN 2533 – ISO PN16 All hydraulic parts are machined from thick parts of plastic (no injection moulding) Plastic used : PP, PVDF, PEHD, PFA, PTFE The shaft sealing is an own SOMEFLU cartridge mechanical seal design Cartridge mechanical seal version : standard seal, injection, rinsing, grease filling or double seal Available in mag-drive version, please see the NP-M product For ATEX (explosion proof), antistatic plastics charged with black carbon are used Max flow : 1500 m³/h Max delivery head : 90m

Request for a quoteResults for

Filling and sealing - Import exportNumber of results

10 ProductsCompany type