- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stage

Results for

Stage - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

The intrinsic quality of the various components, sub-assemblies and software is checked at each stage of design and manufacturing. During the pre-validation phases, performance, durability, and efficiency goals are meticulously assessed and cross-checked with the obligations defined in the specifications. These efficiency targets are cross-referenced and verified with our customer upon commissioning of the equipment, following the implementation of a duly developed validation protocol.

Request for a quote

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Position indicator plastic. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment with no end stop. The position indicator displays in 0.1° increments clockwise. The angle of rotation is indicated directly on the large LCD display. The rotary stage rotates anticlockwise. Reset, chain dimension and offset settings can be made via the keypad. 2 years battery life. The battery is quick and easy to replace. The mounting position of the position indicator is set in 4 positions using one screw. Transmission ratio 211611008 = 501 211611012 = 551 211611025 = 501 The modular design enables the rotary stage to be easily combined with other items of the same size. Drawing reference Assembly position of position indicator a) top (standard) b) right c) bottom

Request for a quote

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment, no end stop. Scale graduation is 10 increments. Transmission ratio 2116008 = 501 2116012 = 551 2116025 = 501 The rotary stage can be easily combined with other modules of the same size. Drawing reference All counterbores to DIN 74Bm (D6)

Request for a quote

NORELEM FRANCE

France

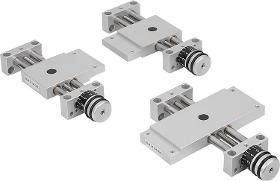

Bearing block and carriage aluminium alloy, anodised. Guide columns stainless steel, ground. Spindle stainless steel, rolled thread. Guide bearing maintenancefree. Version Radial play on guide < 0.02 mm. No axial backlash. Spindle selflocking, with additional lock. Note The almost playfree guides and absolutely playfree spindle allow for adjustment without the need to loosen or clamp the spindle. The scale graduation is in 5 or 10 increments; 1 increment corresponds to 0.1 mm of travel. The cross stage can be easily combined with positioning stages, vertical stages and other accessories of respective size by the modular principle.

Request for a quote

NORELEM FRANCE

France

Aluminium outer ring and inner ring. Iglidur® J plastic slide elements. Stainless steel A2 screws. Version Anodised outer ring and inner ring. Note Aluminium plain bearings with replaceable, high performance material glide elements for rotary stages. Such a combination of materials guarantees absolutely lubricant and maintenancefree running. Simple assembly. High wear resistance. For high loads, high rigidity.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Base and rotary table aluminium alloy. Hollow shaft stainless steel. Preloaded worm gear steel. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Rotary positioning stages for motorised adjustment and positioning tasks. The preloaded worm gear runs virtually playfree. The bearing of the worm shaft offers maximum radial rotational accuracy. Cables can be routed through the large bore in the hollow shaft. The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quoteResults for

Stage - Import exportNumber of results

8 ProductsCompany type