- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting of tubes

Results for

Cutting of tubes - Import export

MONGIN

France

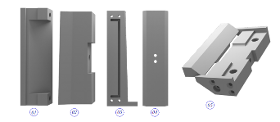

CUTTING AFTER TUBES FILLING TYPE OF MACHINES : UNIPAC, TONAZZI, KALIX, AXIOMATIC, ... On your tube fillers lines, once tubes filled and sealed, they are cut using a knife and a counter knife. N°1 Counter knife UNIPAC N°2 Knife UNIPAC N°3 Moving blade TONAZZI N°4 Fixed knife TONAZZI N°5 AXIOMATIC cutting die

Request for a quote

MONGIN

France

Cutting after tubes filling N°1 - Blade N°2 - Counter blad

Request for a quote

EID

France

The insulated tube is used to manufacture tubing. In 20, 25 or 30 m insulated coils, it can be cut, flared or crimped on-site.Black elastomer insulation (13 or 19mm) is generally used in Industrial refrigeration or in very humid regions. The copper coil offers the advantage of being independent and can be cut to the required length. Tubes are already insulated which saves time during installation. Elastomer-insulated tube only exists in mono-tube.

Request for a quote

EID

France

The insulated tube is used to manufacture tubing. In 20, 25 or 30 m insulated coils, it can be cut, flared or crimped on-site.Black elastomer insulation (13 or 19mm) is generally used in Industrial refrigeration or in very humid regions. The copper coil offers the advantage of being independent and can be cut to the required length. Tubes are already insulated which saves time during installation. Elastomer-insulated tube only exists in mono-tube.

Request for a quote

DOREY

France

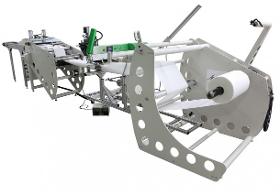

The new Miller Weldmaster filter tube line uses our experience from our previous filter systems and introduces revisions that will make filter tube production even easier. This system makes loading your material easier by giving a laser guideline to help ensure the roll is positioned properly which makes set up easier. From the unwind your material will be guided into the heat seamer with the help of a pre fold system and an adjustable tubing guide which will help you make perfect diameter tubes. The tube will then be brought into the conveyor cutter system which will cut the tubes to the exact length you need and our newly designed sweep system will allow you to push your finished tubes off the side into a take away bin. FEATURES, FUNCTIONS, & BENEFITS No operator involvement reducing labor. It is capable of welding up to 90 feet per minute depending on the fabric which will help increase production.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Cutting of tubes - Import exportNumber of results

5 ProductsCountries

Company type