- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyors

Results for

Conveyors - Import export

FEMIA INDUSTRIE

France

Installed at the line infeed of granular products such as peas/flageolet beans, it extracts small size waste and sticky waste as well as large waste. Machine primarily comprised of a drum of which the perforations of the final section are adapted to the product processed. Continuous cleaning of the machine thanks to its system of brushes and scrapers. Products to be processed exit from the 3rd section of the drum. Collection and discharge of waste thanks to a conveyor inside the drum (except for small size waste at the beginning of the machine).

Request for a quote

FEMIA INDUSTRIE

France

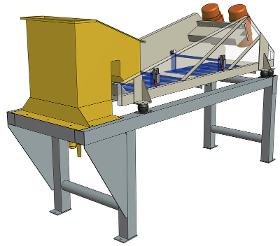

Provides receiving, storage and feeding of the product downstream. The dimensions can be adapted according to the capacity of the line and the means of unloading raw materials used. A conveyor belt with high sides which provides the storage and transport of products.

Request for a quote

FEMIA INDUSTRIE

France

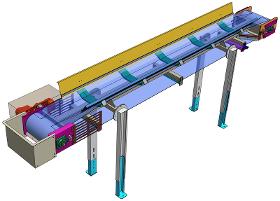

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

FEMIA INDUSTRIE

France

Transfers and feeds the product in a piece of equipment located downstream. Adapted according to your needs and your production.

Request for a quote

FEMIA INDUSTRIE

France

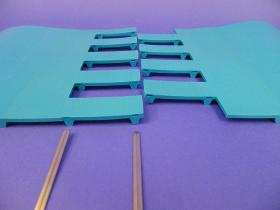

According to your needs, transfers and/or elevates products to a machine located downstream. Can be adapted according to your needs and capacities. Increased reliability thanks to its stainless steel structure. Better preservation of the product thanks to its plates with or without plastic flights.

Request for a quote

FEMIA INDUSTRIE

France

The conveyor provides the product transfer to the machine located downstream. The distributor evenly and continuously transfers your products to several machines downstream. Several outlets and fully adjustable deflector flaps guarantee ideal distribution of your products between the various outlets. Can be adapted and customised according to your needs and capacities (length, width, number of outputs).

Request for a quote

FEMIA INDUSTRIE

France

Saws the husked ears of corn into several pieces (1 to 3). Capacity (automatic feeding version) of 110 ears/minute with the ACC feed system of the cutter. Capacity (manual feeding version) of 60 ears/minutes with two operators. Machine primarily comprised of an automatic feed (automatic feeding version only), a roller conveyor and a cutting head with circular saws. For the two versions, an operator manages the orientation of the ears on the conveyor belt Roller conveyor for visual control and feeding the saw. Adjustment of the cutting of the ends of the ears and of the pieces for a desired length.

Request for a quote

FEMIA INDUSTRIE

France

Installed at the inletof the line for granular products such as peas/flageolets, it removes small waste, sticky waste as well as large waste. Machine mainly consisting of a drum whose perforations in the final section are adapted to the product being treated. Continuous cleaning of the machine thanks to its system of brushes and scrapers. Exit of the products to be treated under the 3rd section of the drum. Recovery and evacuation of waste thanks to a belt conveyor placed inside the drum (except for small waste at the beginning of the machine).

Request for a quote

AVM AUTOMATION

France

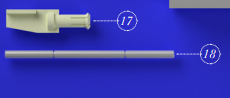

This retractable stop is drived by a double-acting pneumatic cylinder. It is retracted by a 90° rotation of the finger in the direction of movement of the pallet or the object to be stopped. When it is engaged to stop the moving element, it is mechanically locked by a toggle joint action which ensures high repeatability of this stop (<0.05 mm with mechanical stop). There are 3 common applications for this retractable stop: • Create a conveyor stop, a stop pallet, a separating stop, a stopper cylinder • Create an intermediate position for a manipulator or a linear pneumatic gantry • Referencing a product on a workstation

Request for a quote

ERO JOINT .TANALS

France

The mechanical fastening system ERO Joint® is available in conveyor belts with a thickness over 1mm. The assembly is made by threading of 3 transversal pins (stainless steel or polyacetal pins can be used). ERO Joint® splice is integrated into the conveyor belt, with no structural, width and colour changes. Tensile Kevlar cord can be embedded in Polyurethane upon request. Anyway using ERO Joint® conveyor belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® conveyor belts are easy to assemble.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. Mechanical splicing system ERO Joint® are also possible in conveyor belts with sealed tension members (like Gates PosiClean® and FlatClean FC12™) ->More about PosiClean® ERO Joint® belt The ERO Joint® conveyor belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

FEMIA INDUSTRIE

France

Washes most vegetables.Machine mainly made up of a washing tank, pumps that allow the creation of turbulent flows, a paddle turnstile to ensure the progression of floating vegetables and a lift belt. Recovery of water in a settling tank at the outlet of the washer and filtration of the water with a rotating wire drum and its scraper to separate the waste. Closed circuit water circulation for low water consumption. Depending on the products treated, a paddle turnstile can be replaced by an insect trap. As an option, a datura trap can be integrated into the washer.

Request for a quote

FEMIA INDUSTRIE

France

Chops maize waste in particular to facilitate future valuation. Machine mainly consisting of a heavy drum (high inertia) and multiple hammers fixed regularly on the cylindrical part of the drum. Several models available depending on the capacity of the product to be shredded. Carrying structure to be added under the equipment to facilitate the exit of the crushed product. Adapted to the architecture of the line and the constraints of the building. Translated with www.DeepL.com/Translator (free version)

Request for a quote

FEMIA INDUSTRIE

France

Designed for your operators for a complete visual inspection and manual removal of waste mixed in with products.

Request for a quote

FEMIA INDUSTRIE

France

Today, waste management has become a genuine challenge in sustainable development and yield on fruit and vegetable processing lines. Femia provides solutions aimed at extracting only the waste, without affecting the processing of good products. According to a model based on green and circular economy, they are then brought together, recovered and recycled.We design, along with you, a logic for customised waste recovery, according to your material recycling objectives (animal feed, farm use with or without composting), energy (methanisation) or incineration with energy recovery. We integrate the recovery approach right from the design phase for your production lines in order to allow your conveyors progressive and facilitated recovery of wastes all throughout theproduction lines.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEMIA INDUSTRIE

France

With the production of deep frozen products, calibration and even sorting can be required aiming for global optimisation of the process and of the storage of the products as well as of their quality. At this step in your production, FEMIA offers various process functions that can be used after deep freezing, such as cleaning, calibration and sorting. Our solutions allow you to effectively sort products according to their grade (peas, cauliflower, broccoli or cut vegetables in particular) in order to limit intermediate storage and the management thereof before deep freezing. Thanks to the sorting and calibration post deep freeze, you can store your deep frozen products in bulk in large containers and pack them as your orders come in, in order to smooth out your production flows.

Request for a quote

FEMIA INDUSTRIE

France

In a fruit or vegetable processing line, storage is often required to feed the line, process the various categories of products and smooth out the flows between the different machines as well as in case of stoppage of the production line.Feed hoppers that depend on the Product Product transport mode or the container The production capacity of the line Buffer hoppers with adjustable feed system.

Request for a quote

FEMIA INDUSTRIE

France

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

FEMIA INDUSTRIE

France

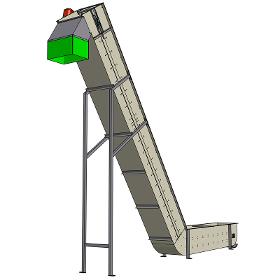

Transfers and lifts the clean product from one piece of equipment to a piece of equipment at a higher level. Several scraper widths are available according to the capacity of the product to be transferred. Adapted to low mass products Adapted to the architecture of the line and to the constraints of the building.

Request for a quote

FEMIA INDUSTRIE

France

Transfers and lifts the product from one piece of equipment to a piece of equipment at a higher level. Adapted to granular products (e.g. peas). Several bucket widths and depths are available according to the capacity of the product to be transferred. Adapted to the architecture of the line and to the constraints of the building.

Request for a quote

FEMIA INDUSTRIE

France

Transfers varied small size products in a flow of water propelled by a pump Ideal for long distance transfers. Characteristics of the hydraulic circuit (length, elevation pressure head, etc.) depending on the required product flow rates.

Request for a quote

FEMIA INDUSTRIE

France

Transfers and lifts the product from one piece of equipment to a piece of equipment at a higher level. Several flighted belt widths are available according to the capacity of the product to be transferred. Adapted to the architecture of the line and to the constraints of the building.

Request for a quote

FEMIA INDUSTRIE

France

Conveying is an important element in the performance of your production lines with the dual challenge of limiting product degradation and losses as well as the proper feed on to the downstream machine, an essential point for optimum performance.Belt conveyor, vibrating conveyor, flighted belt elevators, scraper or bucket elevators, hydraulic transporters, we can adapt many conveying solutions to your lines. Our conveying systems must be selected according to the architecture of the preparation line and products processed in order to represent the solution that will provide you with the best performance and meet the particular challenges of your production.In addition to the diversity of the machines that we can apply to your line, our know how resides in our ability to adapt to your needs. We propose a solution that aims to optimise the layout for a minimum amount of space occupied while still including the maintenance constraints.

Request for a quote

FEMIA INDUSTRIE

France

Suitable for multiple products (except for leafy vegetables).Decrease in the product temperature by several tens of degrees according to the ambient temperature. Low water consumption, respect for the product and the environment. Possibility of filtering the air intake to the cooler.

Request for a quote

FEMIA INDUSTRIE

France

Precise control of the parameters and homogeneous processing of the product by maintaining the temperature through the entire thickness of the product layer for the time required for blanching (and even pre cooking) the processed products. High material yield by preserving as best as possible the organoleptic qualities of the processed products. Minimum water consumption according to the operating mode selected. Optimisation of the dimensions of the equipment according to the range of products to be processed and of the space constraints of the installation zone.

Request for a quote

FEMIA INDUSTRIE

France

Blanching, pre cooking, cooling… continuous thermal treatments are our other expertise. Stopping enzymatic activity, de aerating products, setting their colour, retaining as much as possible the Brix degrees and flavours; those are all of the challenges in thermal treatments of products in tins preserved or deep frozen with an objective of food quality and safety. We offer a large choice of machines that are designed for the better answer to the customer application which also depend on their quality and operating cost targets. Our blanchers, blancher coolers and coolers are designed and sized for the need according to the products to be processed; according to whether it entails tins preserved or deep frozen food products. designed for the required capacity; dimensions are defined on a case by case basis (length / width). This equipment makes it possible to blanch in hot water mode and/or in steam mode and/or in mixed mode; cool in water and/or cold water and/or air mode.

Request for a quote

FEMIA INDUSTRIE

France

Removes the cores from cauliflower or broccoli while creating florets Capacity of 120 heads/minute. Machine primarily comprised of a conveyor belt feed, two symmetric lines (belts with cups, cutting head, outlet elevator) and a waste extraction elevator. Height adjustable cutting head. A single lane Decora with a capacity of 60 heads/minute is also available.

Request for a quoteResults for

Conveyors - Import exportNumber of results

86 ProductsCountries

Company type