- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamp collars

Results for

Clamp collars - Import export

NORELEM FRANCE

France

Housing steel. Cage plastic. Balls steel. Note The linear ball bearings correspond to series 3 of ISO 10285. With doublesided seal. The linear ball bearings have a plastic cage which results in quiet and outstanding running properties. With flange for direct mounting on the housing. Linear ball bearings with doublesided seal should be greased before installation. The specified load ratings apply with the use of hardened and ground shafts. Precision guide shafts 21595. Fastening screws 07160.

Request for a quote

NORELEM FRANCE

France

Shell, ballbearing steel. Cage, plastic. Balls, steel. Note With seals both ends. The linear ball bearing is secured using DIN 471 / 472 circlips. Application Suitable for applications where installation space is limited.

Request for a quote

NORELEM FRANCE

France

Outer jacket stainless steel. Cage stainless steel. Balls stainless steel. Note The linear ball bearings correspond to series 3 of ISO 10285. With doublesided seals and a stainless steel cage. The bearing is secured with DIN 471/472 circlips. Linear ball bearings with doublesided seals should be greased before installation. The specified load ratings apply with the use of hardened and ground shafts.

Request for a quote

NORELEM FRANCE

France

Housing anodised aluminium. Bearing surface Frelon (Teflon plus proprietary fillers). Virtually chemically inert. Selflubricating (no additional lubrication required). High temperature range (240 °C to +260 °C). Dampens vibrations. High static load capacity projected surface area x P (P = 1034 N/cm²) Suitable for food, pharmaceutical, medical and chemical applications. Insensitive to dirt.

Request for a quote

NORELEM FRANCE

France

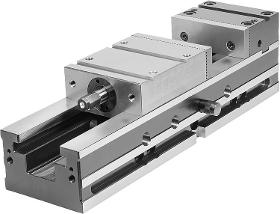

Housing steel. Clamping lever plastic. Threaded spindle grade 12.9. Version Housing nickelplated. Clamping lever, spindle black oxidised. Note Manually operated clamping elements for static clamping tasks. Manual clamping process using the freely adjustable clamping lever. The floating clamp ensure symmetrical application of force onto the rail. Up to 50,000 static clamping cycles (B10d value). In general, a friction connection is created between the clamping element and the the linear guide on the open faces of the profile guide rail so that the ball guide tracks are not damaged. The retaining force is tested on an oil smeared profile guide rail. An adapter plate, dependent on the type of carriage used, is required for height adjustment.

Request for a quote

NORELEM FRANCE

France

Body steel. Cam levers cast aluminium. Version Body black oxidised. Tnut electro zincplated. Cam levers black powder coated. Note The clamp module is inserted into the Tslot from above and secured using the cam lever, no other tools required. Advantages The eccentric clamp modules can be used on conventional aluminium profile systems or on Tslot tables as stops, fasteners or clamps for components and workpieces.

Request for a quote

NORELEM FRANCE

France

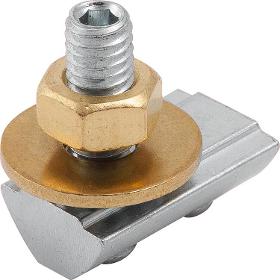

Slot key, grub screw and serrated washer, steel. Nut and washer, brass. Version Slot key, grub screw and serrated washer, electro zincplated. Note For protecting installations and persons. Connectors for earthing aluminium profile structures and interconnecting the aluminium profiles by integrating them into the protective earth (PE) system. Conductive contact is established through defined destruction of the oxide layer in the slot base and on the slot flanks. The cable lug must be positioned between the serrated washer and the washer during assembly.

Request for a quote

NORELEM FRANCE

France

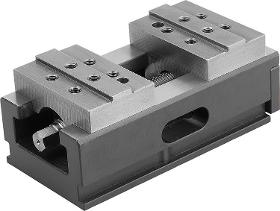

Body and jaw holder hardened and ground. Note for ordering: Supplied with hexagon crank handle. Order jaw plates separately. Note: Mechanically operated centric vice. Suitable for automation: prepared with gripper slot for handling systems. Flexible mounting: suitable for zero-point systems, mounting on machine tables or on custom systems via a baseplate. Centring precision: +/- 0.02 mm. The use of a torque wrench is recommended to achieve a controlled clamping force. Features: Clamping slide and spindle nut in one piece Slots and fastening threads for mounting attachment jaws Reversible jaws (accessories) with lateral thread for workpiece stop enables a wider clamping range Good swarf and coolant removal

Request for a quote

NORELEM FRANCE

France

NC vices can be used for a wide range of clamping tasks: Repeat accuracy ≤0.01 mm Fixed jaw locked in all directions (X,Y,Z) Vertical use directly on the machine table Wide clamping range by using attachment step jaws Can be laid on the side, with fastening holes for slot spacing of 63 mm and 100 mm Quick pre-adjustment of the clamping range using locking pins Basic equipment includes two reversible screw-on jaws and one crank handle

Request for a quote

NORELEM FRANCE

France

Ratchet elements are used to connect two components together in any angular position with a positive fit. The ratchet elements with internal toothing (Forms A–D) can be combined with the ratchet elements with external toothing (Forms E–H) in any way depending on the application and installation possibilities. The springs mean that a new angular position can be quickly implemented.

Request for a quote

NORELEM FRANCE

France

Two-piece shaft collars surround the shaft with a uniformly distributed clamping force. This leads to a dimensionally precise fit and very high retaining forces without damaging the shaft. The shaft tolerance should lie within h11. Two-piece shaft collars can be quickly and easily mounted or removed without dismantling other components.

Request for a quote

NORELEM FRANCE

France

Clamping joints are used to clamp round cross sections (bars, tubes, etc.) and are infinitely adjustable. The simple design together with the adjustable clamping lever permits rapid clamping.

Request for a quote

NORELEM FRANCE

France

Clamping levers with safety function prevent changes in the locking point through accidental opening or closing. In the default position, the lever can be freely rotated and has no connection to the clamping point. The grip lever only engages when pushed down and the clamp can the loosened or tightened. A spring sets the lever automatically into the default position when released.

Request for a quote

NORELEM FRANCE

France

It is recommended that the cam lever is in a vertical position when the collet is positioned in the bore. The function of the clamping system was tested in bores with tolerance H7. All values for retaining force are guide values and are given without safety factor. The suitability for the respective application must be checked by the user. Advantages: Two components can be joined together without tools. The components are perfectly centred in the clamped state. The compact design means that the mandrel collet with cam lever can even be used in blind holes. There are no specific dimensional requirements for the holes. Additionally, the surfaces and design do not need to have any specific properties. Functional principle: The clamping system is inserted in the hole in the open state. At the beginning of the locking process, the mandrel collet expands and clamps itself in the lower component. The integrated disc spring assembly creates a positive down force

Request for a quote

NORELEM FRANCE

France

Enter the desired lever colour here. The standard colours are: Black grey clamping lever, traffic red push button. Orange clamping lever, black grey push button. Traffic red clamping lever, black grey push button. Where L ≥ 60 mm the thread length is 60 mm. On request: Other threads, screw lengths and special versions. Dimension “H1” available in other lengths at extra charge. Drawing reference: 1) flat point DIN 78

Request for a quote

NORELEM FRANCE

France

Handle powder-coated, fine-textured structure. Steel parts black oxidised. Note: Standard colours are: black or ruby red RAL 3003.

Request for a quote

NORELEM FRANCE

France

Other threads, screw lengths and special versions. Dimensions “H1” and “A” available in other lengths at extra charge.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Heavy-duty forged latches for high tensile loads. Primarily used on utility vehicles, agricultural and construction machinery. A ratchet prevents unintentional opening when closed. To compensate for tolerances or to create enough tension the bail can be adjusted using the spindle D1. Order required catch plate version separately. The retaining force F1 applies to the latch, not the catch plate.

Request for a quote

NORELEM FRANCE

France

Pneumatic clamps have the following advantages compared to hand clamps: The operator is relieved of frequent clamping. Several clamps can be activated at the same time and can be closed in a specific sequence. Single or multiple clamps can be activated from varying positions by machine control or hand control. Because of the toggle system: the clamp remains closed if the air supply fails. the air consumption is low due to the large end ratio. pivoting the clamping arm achieves a large opening travel. optimum force and movement ratios are achieved. VL = air consumption per complete cycle in dm³ at 6 bar. Selection criteria: To select the correct size of pneumatic clamps, the possible clamping force at 6 bar (any compressed media are permissible, maximum pressure 10 bar) is specified besides the retaining force. F3 is the possible clamping force that the clamp exerts on the end of the clamping arm, F4 the force it exerts on the fulcrum side.

Request for a quote

NORELEM FRANCE

France

The mini clamp is characterised by its small size, positioning accuracy of the clamping arm, and lightweight construction. Mini clamps are fully self-locking. The clamping force is guaranteed even when the pressure is removed through the over dead-centre position of the toggle lever on the clamping arm. The permanent lubrication and special bearing bushings make the mini clamps maintenance-free. They can be operated using dry, oil-free air. The manual closing and locking using the hand lever. Pneumatic opening and closing. Attention: A 5/3-way valve is required, middle position vented. On request: Clamping arm without holes.

Request for a quote

NORELEM FRANCE

France

Swing clamps are used where low clamping forces suffice or where the clamping point must be free when mounting and removing the workpiece. The block form of the housing offers universal fastening possibilities. The magnetic piston is primed for electrical end position feedback. Including screw and lock washer for fastening the clamping arms (accessories). The swing action of the clamp should not be blocked. F1 = at 6 bar (max. operating pressure).

Request for a quote

NORELEM FRANCE

France

Latches with draw bail for securing and locking hatches, container lids, machine cladding etc. By exceeding the dead centre they resist vibration. The locking force is applied by drawing on the bail. The latches can be screwed down or riveted. We recommend using countersunk screws for fastening the components. Order catch plates separately.

Request for a quote

NORELEM FRANCE

France

Maintenance-free high quality link bushings. Sustainable constant use of force during opening and closing. Optimum stability through the conical, U-profile clamping arm. Accessory: 05280 Protective caps 07111 Ball-end thrust screws, stainless steel 07119 Thrust screws, stainless steel 07120 Grub screws with thrust point DIN 6332 07140 Thrust pads DIN 6311 Drawing reference: 1) stop pin position 1 2) stop pin position 2

Request for a quote

NORELEM FRANCE

France

The toggle clamp adjusts automatically to the height of the workpiece. Infinitely adjustable clamping height within 35 mm with approximately constant clamping force without manual adjustment of thrust screw position. The clamping force can be adjusted up to 2.500 N according to requirements using a set screw under the lever in the hinge. The hole pattern in the baseplate is suitable for millimetres and inches.

Request for a quote

NORELEM FRANCE

France

Steel parts electro zinc-plated. Hinge pins tempered. Plastic handle oil-resistant. Note: See 05200 – 05280 for accessories.

Request for a quote

NORELEM FRANCE

France

The screw is tightened or the clamping lever is turned to expand the two wedges in the hole. The infinitely adjustable shaft collar enables one or more stop elements with various thicknesses to be securely fixated. Application: These clamping pins are perfect for fixing standard stop elements with various thicknesses to hole grid boards / welding tables with hole Ø 16 mm or 28 mm. Advantages: Infinitely adjustable clamping range of 0-36 mm and 0-75 mm. Not affected by the diameter or surface quality of the bore (up to H12). Clamping range can be easily preset using the scale. Gentle clamping in the bore. Pull-down effect even with thin table material (≥8 mm or ≥4 mm). Compatible with conventional stop elements.

Request for a quote

NORELEM FRANCE

France

The functioning principle make the wedge clamps ideal for series clamping. The wedge form can exert high clamping forces. These wedge clamps can be mounted in grid holes or T-slots. Tightening the socket screw moves the wedge down and the jaws out pressing the workpieces against the fixtures fixed stops. The wedge has a slightly elongated hole allowing for movement to compensate for tolerances. Spread width: M8 = ±0.5 mm M10 = ±1.0 mm M12 = ±1.0 mm M16 = ±1.5 mm Drawing reference: D) DIN 6912 cap screw 1) Jaw face smooth 2) Jaw face serrated 3) Wedge clamps 4) Workpiece 5) Fixed stop

Request for a quote

NORELEM FRANCE

France

Fasten the floating clamp to the fixture with the M12 screw. Adjust the height stop and the swivel range using the blue sleeve and lock with the 3x2.5 mm grub screws. When setting the height leave generous clearance above. For safe operation the M12 tapped hole must always be closed. For specific clamping applications the standard jaws can be altered or replaced. Form B: Fasten the floating clamp with M6 fastening holes to a fixture. Adjust the height stop and pivot range using the blue adjusting sleeve and clamp with grub screws (4x AF 2.5). When setting the height limit, allow ample play at the top. For specific clamping situations, the standard jaw plates can be modified or replaced.

Request for a quote

NORELEM FRANCE

France

Cam tool steel, hardened and black oxidised. Shaft carbon steel, hardened and black oxidised. Grip carbon steel, black oxidised. Ball knob black thermoset PF 31. Note: Admissible hand force for the handle. Accessory: Standard handles 06355. Screw-in handles with adjustable torque 06357.

Request for a quoteResults for

Clamp collars - Import exportNumber of results

66 ProductsCompany type

Category