- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pneumatics

Results for

Pneumatics - Import export

NORELEM FRANCE

France

Doubleacting pneumatic cylinder acc. to DIN ISO 6432. Piston rod with external thread, position detection for proximity switch and flexible damping on both sides.

Request for a quote

NORELEM FRANCE

France

Doubleacting pneumatic cylinder acc. to DIN ISO 21287. Piston rod with internal or external thread, position detection for proximity switch and flexible damping on both sides. Thanks to their compact structural dimensions, compact cylinders are ideal for use in installation spaces where space is limited.

Request for a quote

NORELEM FRANCE

France

Doubleacting pneumatic cylinder in constructionoptimised design acc. to DIN ISO 15552. Piston rod with external thread, position detection and adjustable pneumatic damping. Due to their robust construction, these cylinders are the preferred choice for numerous applications.

Request for a quote

NORELEM FRANCE

France

The collet is opened by applying compressed air to the "open" port. The collet is closed (for clamping) by applying compressed air to the "close" port. The pneumatic connections can be screwed on either from below or from the side. If the air is connected from below, the side ports must be closed. Machining the collet for external clamping: The negative form of the workpiece to be clamped is machined into the collet. Free-form and asymmetrical contours are possible. Different workpieces can be clamped quickly and securely by simply exchanging the collet. The collet can be milled down to height H2. This enables multiple workpiece contours to be machined into one collet. Repeat accuracy for workpiece: +/-0.03 Repeat accuracy after replacing the collet +/- 0.02 The collet radial clamping travel is 0.15 mm per clamping segment. To prevent damage the collet should not be tightened without a workpiece or clamping ring in place. The operating air pressure should lay between 0.45 - 0.55 MPa.

Request for a quote

NORELEM FRANCE

France

Pneumatic clamps have the following advantages compared to hand clamps: The operator is relieved of frequent clamping. Several clamps can be activated at the same time and can be closed in a specific sequence. Single or multiple clamps can be activated from varying positions by machine control or hand control. Because of the toggle system: the clamp remains closed if the air supply fails. the air consumption is low due to the large end ratio. pivoting the clamping arm achieves a large opening travel. optimum force and movement ratios are achieved. VL = air consumption per complete cycle in dm³ at 6 bar. Selection criteria: To select the correct size of pneumatic clamps, the possible clamping force at 6 bar (any compressed media are permissible, maximum pressure 10 bar) is specified besides the retaining force. F3 is the possible clamping force that the clamp exerts on the end of the clamping arm, F4 the force it exerts on the fulcrum side.

Request for a quote

NORELEM FRANCE

France

The mini clamp is characterised by its small size, positioning accuracy of the clamping arm, and lightweight construction. Mini clamps are fully self-locking. The clamping force is guaranteed even when the pressure is removed through the over dead-centre position of the toggle lever on the clamping arm. The permanent lubrication and special bearing bushings make the mini clamps maintenance-free. They can be operated using dry, oil-free air. The manual closing and locking using the hand lever. Pneumatic opening and closing. Attention: A 5/3-way valve is required, middle position vented. On request: Clamping arm without holes.

Request for a quote

NORELEM FRANCE

France

Swing clamps are used where low clamping forces suffice or where the clamping point must be free when mounting and removing the workpiece. The block form of the housing offers universal fastening possibilities. The magnetic piston is primed for electrical end position feedback. Including screw and lock washer for fastening the clamping arms (accessories). The swing action of the clamp should not be blocked. F1 = at 6 bar (max. operating pressure).

Request for a quote

NORELEM FRANCE

France

Extruded section, aluminium EN AW6060. Version Hard anodised aluminium, 50 µm. Hardness 500 HV. Note The aluminium guide rail has good thermal conductivity and importantly heats only at continuously very high speeds. ** lengths L2 = 20 mm * and L = 500 mm included L2 and L only available in full mm.

Request for a quote

NORELEM FRANCE

France

Sliding carriage Base structure in extruded section, aluminium EN AW6060. Sliding elements Maintenance free plain bearing iglidur® J. Version Eloxalcoated E6/EV1. Black thermoplastic Note With a low rate of inerita, high accelerations and short term extreme speeds up to 30 m/s are possible. DryLin® T linear glide guides are resistant to dirt and corrosion and are adjustable, maintenancefree and quiet. Application temperature max. 80 °C. As no lubricants are used they are recommended for use in food, medical, and clean room technologies. Manual clamping was developed for simple functions. Polymer under constant pressure has a tendency to creep which causes a decrease in clamping force over time (up to 70%), which means that no safetyrelevant parts should be clamped. Suitable guide rails see 21200. Drawing reference 1) manual clamping

Request for a quote

NORELEM FRANCE

France

Base and rotary table aluminium alloy. Hollow shaft stainless steel. Preloaded worm gear steel. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Rotary positioning stages for motorised adjustment and positioning tasks. The preloaded worm gear runs virtually playfree. The bearing of the worm shaft offers maximum radial rotational accuracy. Cables can be routed through the large bore in the hollow shaft. The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment, no end stop. Scale graduation is 10 increments. Transmission ratio 2116008 = 501 2116012 = 551 2116025 = 501 The rotary stage can be easily combined with other modules of the same size. Drawing reference All counterbores to DIN 74Bm (D6)

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy, anodised. Guide columns stainless steel, ground. Spindle stainless steel, rolled thread. Guide bearing maintenancefree. Version Radial play on guide < 0.02 mm. No axial backlash. Spindle selflocking, with additional lock. Note The almost playfree guides and absolutely playfree spindle allow for adjustment without the need to loosen or clamp the spindle. The scale graduation is in 5 or 10 increments; 1 increment corresponds to 0.1 mm of travel. The cross stage can be easily combined with positioning stages, vertical stages and other accessories of respective size by the modular principle.

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy, anodised. Guide columns stainless steel, ground. Spindle stainless steel, rolled thread. Guide bearing maintenancefree. Position indicator plastic. Version Radial play on guide < 0.02 mm. No axial backlash. Spindle selflocking, with additional lock. Note Due to the practically playfree guides and absolutely playfree spindle, loosening or clamping of the spindle is not required during adjustments. Digital position indicators with 0.1 mm display accuracy, digits increase with right rotation. The display value of the position indicator can be adjusted by turning the carrier ring. The mounted position of the position indicator can be set in 4 positions with a screw. Within the respective sizes, the positioning stages can be easily combined using the modular principle. Drawing reference Assembly position of position indicator a) top (standard) b) right c) bottom d) left

Request for a quote

NORELEM FRANCE

France

Backstop steel. Axis steel. Cage polyamide, carbonfibre reinforced. Version Electro zincplated Cage black. Note The backstop element is matched to the aluminium profiles for roller rails and can be mounted on them quickly and easily. It prevents reverse movements of items on the roller tracks. No tools required. Suitable for aluminium profiles Type B and I.

Request for a quote

NORELEM FRANCE

France

Ball stainless steel. Housing steel. Cage polyamide, carbonfibre reinforced. These ball transfer units are matched to the aluminium profiles for roller rails and can be mounted on them quickly and easily. For flexible movements in two dimensions. With a lowwear and lowfriction ball rollers. No tools required. Suitable for aluminium profiles Type B and I.

Request for a quote

NORELEM FRANCE

France

Roller and cage polyamide, glassbead reinforced. Steel axis. Cage black. Roller available in different colours. The roller elements are matched to the aluminium profiles for roller rails and can be mounted on them quickly and easily. No tools required. The compact design with a small centre distance is optimally designed for the lowvibration conveyance of sensitive items. Suitable for aluminium profiles Type B and I.

Request for a quote

NORELEM FRANCE

France

Bearing flanges and fastening pieces PAGF. Bolts steel. Black. Bolts electro zincplated. Two bearing flanges combined with a D50 type I aluminium profile tube (10050) form a feed roller (loadbearing roller). The bearing flanges are simply pressed into the aluminium profile tube. These can be used for many conveyance tasks. The bearing flanges have ball bearings and springloaded fastening spigots which enable transport rollers to be retrofitted into existing structures. A roller conveyor is created when several transport rollers are mounted in series. Two bearing flanges are required for a transport roller.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Clamping angle diecast zinc. Grip diecast zinc DIN EN 12844. Steel parts stainless steel 1.4305. Cam lever cast aluminium. Body steel. Version Clamping angle painted aluminium tone. Handle powdercoated. Stainless steel bright. Slot key electro zincplated. Cam lever black powdercoated, steel parts black oxidised. Note The clamping angles are used for connecting two profiles of the same series that have contact on the side faces and cross at any angle. Loosening the screw releases both clamps allowing free rotation and sliding along the slots. The clamping angles are generally used in pairs or in combination with a joint angle.

Request for a quote

NORELEM FRANCE

France

Angle diecast zinc. Screws and slot nuts steel. End cap polyamide, fibreglass reinforced. Version Angle painted aluminium tone. Screws and slot nuts electro zincplated. End cap black. Note Suitable for reinforcing profile constructions and for frictional connection of profiles with each other without machining. Can also be used as fastening element (e.g. bracket) for any components. The angles have centring lugs for accurate and twistproof mounting. The centring lugs can be removed if necessary by breaking off i.e. for mounting plates. The open side can be closed off with the end cap.

Request for a quote

NORELEM FRANCE

France

The pneumatic swing clamp is suitable for clamping workpieces from above. The swivel and clamping function occurs pneumatically. The swivel function enables unobstructed insertion and removal of the workpiece. Optimum accessibility to the workpiece is guaranteed. The foot of the housing offers universal fastening possibilities, enabling the swing clamp to be optimally aligned with the workpiece being clamped. The swing clamps are available in left or right swivelling versions. Pneumatic swing clamps can also be placed in multiple positions on the workpiece and operated in a particular order. They can be controlled manually or automatically.

Request for a quote

NORELEM FRANCE

France

Workpieces are clamped and released by compressed air. The possible clamping diameter is from 16 to 20 mm. Material: Body, stainless steel. Seal, NBR. Version: Stainless steel bright. Note for ordering: Cylinder head screws M4X35 for fastening from below are included with delivery. Cylinder head screws with low head M5 for fastening from above are not included with delivery. Note: Installed dimensions for plate thickness 6 mm. The stated retaining forces are related to an operating pressure of 0.5 Mpa and a surface quality of Ra 1.6 µm. Repeat accuracy in this case is ±0.2 mm.

Request for a quote

NORELEM FRANCE

France

Housing hardened and black oxidised. Contact faces ground. Note: Locating bushes are placed in a fixture or interchangeable subplate and form the counterpart to the locating cylinder. The locating bushes are centred in a reamed hole and then fastened with 4 screws. The balls of the locating cylinder engage in the groove in the locating bush, thereby forming a fast, secure and highly accurate changeover unit, and reducing setup and changeover times. Attention: Please observe installation notes of the locating bushes.

Request for a quote

NORELEM FRANCE

France

Housing hardened and black oxidised. Contact faces ground. Note: This positioning and clamping system is especially suitable for installation in fixtures (plates, clamping tower blocks, etc.) in all mounting positions. The modular design allows the number of and distance between the locating cylinders to be ideally adjusted to suit the clamping task. Due to the small diameters, the spacing between the locating cylinders can also be reduced. The 3 clamping balls are mechanically released through control of the locating cylinder with the "opening" connection. The 3 clamping balls move inward and the fixture can be changed quickly. For clamping, the air is taken from the "opening" connection and the "clamping" connection then receives air on the locating cylinder. The 3 clamping balls are mechanically driven outward again and the new fixture is clamped. To achieve optimal retaining force, the locating cylinder remains connected to the air.

Request for a quote

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Position indicator plastic. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment with no end stop. The position indicator displays in 0.1° increments clockwise. The angle of rotation is indicated directly on the large LCD display. The rotary stage rotates anticlockwise. Reset, chain dimension and offset settings can be made via the keypad. 2 years battery life. The battery is quick and easy to replace. The mounting position of the position indicator is set in 4 positions using one screw. Transmission ratio 211611008 = 501 211611012 = 551 211611025 = 501 The modular design enables the rotary stage to be easily combined with other items of the same size. Drawing reference Assembly position of position indicator a) top (standard) b) right c) bottom

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

The pneumatic hold-down clamp is suitable for clamping workpieces from above. This clamp is operated with standard pressure compressed air. The large swivel angle of the clamping arm makes it easy to insert and remove the workpieces without any obstructions, guaranteeing optimum accessibility to the workpiece. The block design of the housing offers universal fastening possibilities, which means that the clamp can be optimally adapted to the workpiece being clamped. Self-aligning pads with a smooth or serrated faces can be fitted in the clamping arm, enabling rough or machined workpieces to be clamped. These pneumatic clamps can be placed in multiple positions on the workpiece and operated in any particular order. They can be controlled manually or automatically. As these clamps are pneumatically actuated, they relieve the operator, particularly where frequent clamping processes are carried out.

Request for a quote

NORELEM FRANCE

France

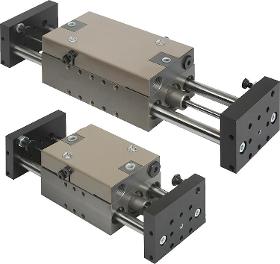

Body and flange plate EN AW5754. Guide shafts steel Version Body, hardcoated Flange plates, anodised. Guide shaft, hardened. Note Maintenancefree pneumatic linear modules with two precision steel shafts and ball guide bushing with wipers. Double acting cylinder drive. All fastening threads have threaded inserts. The as accessory available shock absorbers and proximity switches can be integrated (no protruding edges). Positive fit construction for hundred per cent reproducibility. Combinations in all sizes and stroke variants are feasible without adapter plates. Repeat accuracies of ±0.01 mm are possible. Specified loads apply by centred carriages. On request Available with locking cartridge as stroke deviation safeguard. Accessory See table for shock absorber, proximitiy switch and plug connector.

Request for a quoteResults for

Pneumatics - Import exportNumber of results

28 ProductsCompany type