- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flow measurements

Results for

Flow measurements - Import export

DELTAFLUID

France

For a better precisionSolder (BW) or flanged connection Material: Standard: carbon steel, stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

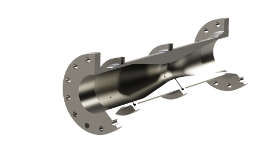

Suitable for small diameters and / or low permanent pressure dropMaterial: Standard: carbon steel, stainless steel, others according to your application. Fluid: liquid, gas, steam. Diameter of pipes: from 50 to 250 mm.

Request for a quote

DELTAFLUID

France

Suitable for large diameters and / or low permanent pressure dropMaterial: Standard: carbon steel, stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

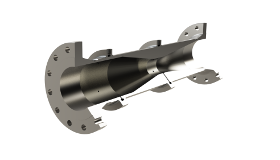

The sonic state of the nozzle means that the flow reaches the speed of sound when going through the throat. Under these conditions, the flow rate depends mainly on the upstream pressure and the fluid temperature. This makes it possible to deliver a stable and perfectly known flow, independent of the downstream pressure conditions of the nozzle. This nozzle is thus used to provide a standard flow value when it comes to calibrating another type of flow meter.

Request for a quote

DELTAFLUID

France

Suitable for large steam flowsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation or solder connection (BW) Material: Standard: carbon steel, stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Suitable for large flows with high speedsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. or solder connection Material: Standard: carbon steel, stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Economical solution thanks to the reduction of upstream and downstream straight lengthsStandard: Element designed on the basis of ISO 5167-1 & ISO 5167-2 or ASME FC-3M. Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application

Request for a quote

DELTAFLUID

France

Recommended orifice plate for dirty, charged or two-phase fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Recommended for viscous fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Recommended for low flow rates and / or viscous fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

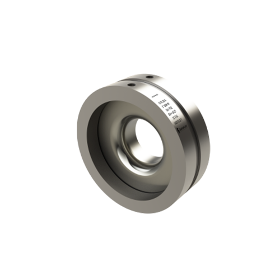

Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Recommended for dirty, charged or diphasic fluidsMounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quote

DELTAFLUID

France

Suitable for large flow rates with low permanent pressure dropSolder (BW) or flanged connection Material: Standard: carbon steel, stainless steel, others according to your application. Fluid: liquid, gas, steam. Diameter of pipes: from 65 to 500 mm.

Request for a quote

DELTAFLUID

France

A flow straightener greatly reduces disturbances in a flow while a conditioner reduces disturbances and also allows a good redistribution of the speed profile, at each point of the section of the pipe. Thus, these devices make it possible to reduce the upstream straight lengths and to improve the measurement accuracy in the case of a flow measurement. They are therefore to be positioned between a pipe fitting (elbow, reduction, etc.) and a flow measurement element while respecting the distances specified in the standard.

Request for a quote

DELTAFLUID

France

Many piping and instrumentation accessories are necessary to implement the flow measurement of a fluid in a pipe: the shutters to isolate the existing pipe in case of intervention, the flanges to fix the primary elements and to connect to the existing process, flow straighteners or flow conditioners to stabilize the flow before the measurement but also condensation pots for steam measurement and finally manifold, pressure transmitter always mandatory for differential pressure flow measurement.

Request for a quote

DELTAFLUID

France

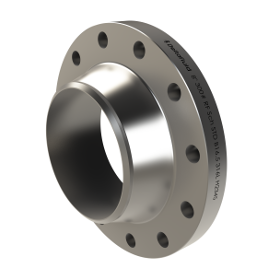

The flanges on the measuring elements and the piping allow easy assembly and disassembly unlike the welded assembly. Different types of flanges are available to meet all standards, all requirements in all areas of activity. Orifice flanges : They are used for flow measurement with orifice plates. They allow, thanks to the integrated pressure taps, to recover high and low pressure (Δp).

Request for a quote

DELTAFLUID

France

Suitable for flow measurement in large pipes, for installations with low pressure dropAverage measurement over the entire length of the tube. Installation on the pipe: compression fitting, flange ISO PN 2.5 to 420 or ASME 150 # to 2500 #, retractable. Material: Standard: 304L / 316L stainless steel, others according to your application.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DELTAFLUID

France

the desired orifice (orifice plate, nozzle) the flanges to fix the orifice the pressure taps (at the flange or in the corners, depending on the primary element chosen) and the impulse tubes integrated or remote 3 or 5 way manifold the preset differential pressure transmitter the built-in temperature sensor (for temperature compensation) in option MOUNTING AND ASSEMBLY DATA: Optimized centering of the measuring element Honing of upstream and downstream pipes to meet roughness criteria Temperature and pressure compensation for gases to achieve very accurate flow measurement Remote mounting of the instrumentation according to the applications CHARACTERISTICS : For orifice plates: see corresponding technical data sheet For nozzles: see corresponding technical data sheet Straight lengths upstream, downstream, roughness and circularity of the tubes, centering measuring element: see details on the FAQ tab on this page ACCESSORIES : Temperature sensor: Sensor mounted on downstream

Request for a quote

DELTAFLUID

France

Orifice plates or diaphragms are the most commonly used primary elements for differential pressure flow measurement. They allow measurement over a wide range of flow rates and for a wide range of pipe diameters. There are several types: the sharp-edge orifice plate, the best known, the other concentric plates with conical inlet and quarter circle plate for the measurement of low flows or viscous fluids and the eccentric plate or segmental plate for the measuring dirty or impure fluids. Finally, the multi-hole / conditioning orifice plate allows a measure of quality while providing a minimum footprint. Inserted within a circular pipe, they create an obstacle, increase the speed of the fluid and generate a pressure difference between upstream and downstream of the restriction. This differential pressure measurement is proprotional to the flow rate value.

Request for a quoteResults for

Flow measurements - Import exportNumber of results

20 ProductsCountries

Company type