- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation

Results for

Automation - Import export

GRAVOTECH

France

TOUCH SCREEN Just press the touch screen and the LW2 takes care of the rest! The door closes automatically, the laser is positioned at the right focus height, the marking is done in a few seconds and the door opens. This laser station does not require training. Just prepare your marking jobs and load them into your industrial marking solution via the USB port. COMPLETE SAFETY This laser marking system is certified as class 1 laser products, allowing use in unrestricted environments: integrated fail-safe relay, protective glass, door closure security, emergency stop, door fitted with sensors and anti-pinch system, integrated extraction and filtration solution to protect users from dust and smoke. Mechanic and electronics are fully protected in a sealed box. Integrated alarms and controls. FLEXIBILITY Large marking area with 3 sided door, marking of a wide variety of parts, from small to big parts, from simple to complex shapes. The LW2 is compatible with most of our laser sources.

Request for a quote

CDA

France

The Ninon Down, an automatic linear labeller, is specifically designed to apply a single label to the bottom of various product shapes, including square, cylindrical, conical, or oval items (bottles, jars, vials, etc.). Equipped with a timing system, it ensures rapid, precise, and efficient product labelling, accommodating a speed of up to 80 products per minute. The Ninon Down stands out for its user-friendly design and control through an intuitive touch screen. Thanks to its versatile application, this linear automatic labeller can be adapted to various sectors, including: Cosmetics and hygiene (soap, shower gel, shampoo, etc.), Food processing (condiments, oil, vinegar, vegetable and fruit jars, etc.), Paint and varnish (buckets, pots, cans, etc.), Chemicals (cleaning products, household items, solvents, detergents, etc.).

Request for a quote

REP INTERNATIONAL

France

REP AUTOMATED SOLUTIONS Automation is adapted to the needs and objectives of each customer. An infinite number of possibilities for the following operations Feeder channels Evacuation Flash and gum cutters Evacuation Spraying of release agent and / or cleaning of the mold Loading of inserts Demoulding of finished parts Visual control of conformity and many others... 3 levels of automation possible o Operator assistance Insert loader o Partial automation Demoulding kit (front, rear top, rear bottom, etc.) o Total automation Robotic cell, brushing on horizontal presses, etc.

Request for a quote

AXON CABLE SAS

France

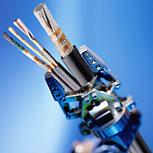

Axomove® is a range of round composite cables specially designed for robotic technology applications. They are able to meet the most demanding requirements of the automation technology. The main characteristics are as follows : good flexlife and resistance to torsion, small dimensions, small bend radius, resistance to oil and solvents, abrasion resistance, EMI protection. Depending on customer requirements, they can be composed of round or flat primary wires or both Insulation : FEP, PTFE, ETFE, PFA, polyimide, vitax™ , PU, ... Shielding for EMI protection when required

Request for a quote

AXON CABLE SAS

France

Flextrack® is a range of high flex flat cables for the automation and robotics industry. They meet the most demanding applications requiring tens of millions of flex cycles. They are designed for high flex applications including Pick and Place industries. Their flat configuration allows for space saving compared to a round cable. Flextrack® laminated flat cables are lightweight and flexible. They resist to high temperatures, repeated flexions and chemical products.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACIMEX

France

Bespoke machines are pieces of equipment installed on production lines (handling line, output line, etc.) and which are used to move different types of heavy loads from point A to point B (storage area). ACIMEX is specialized in the manufacture of equipment fitted with suction cups which detect the weight, the diameter and the size of heavy loads in order to grip them in complete safety and so facilitate the production process. Using its know-how in custom design and manufacture, ACIMEX innovates constantly to create bespoke machines that meet the needs of each of its customers. Two types of bespoke machines have been developped at the beginning of 2017 in ACIMEX factories, one to grip sandwich panels of 160 kg safely, and the other to move and store graphite electrodes. Evidence, once again, that ACIMEX offers turnkey solutions to its customers, and this regardless of the type of handling performed.

Request for a quoteResults for

Automation - Import exportNumber of results

7 ProductsCountries

Company type