- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- assembly installations

Results for

Assembly installations - Import export

JAD GROUPE

France

Length 1800 mm Light oak look 5 HPL slats, 18 mm thick 35 mm diameter tubular steel legs Legs treated with zinc primer (high zinc content 90%) Hammered grey anthracite epoxy paint finish Supplied in kit form with assembly accessories For installation or embedding

Request for a quote

NORELEM FRANCE

France

Magnetic tape, magnetised plastic sheet. Carrier band steel. Cover band stainless steel. Version Scale with incremented coding. Pole length 5 mm. Note Simple adhesive mounting; selfassembly possible. Required tape length calculated from measuring path + sensor length "L" + (2 x run or return "B"). L = see drawing of sensor used. B = 10 mm (run and return). Technical data Coefficient of expansion (11 ± 1) x 106/K (spring steel) Temperature range Ambient temperature 20–70°C Storage temperature 40–70°C Assembly Installation using the preaffixed doublesided adhesive tape must be carried out according to the enclosed user information. On request Other lengths from 0.1–100 m, in increments of 0.1 m. Note Relative humidity 100%. Dewing is permissible. Drawing reference 1) Cover band A = 0.176 mm 2) Magnetic tape M = 1.0 mm 3) Carrier band T = 0.3 mm 4) Adhesive tape K = 0.1 mm 5) Required tape length = measuring path + L + 2 x B 6) Measuring path

Request for a quote

NORELEM FRANCE

France

Housing aluminium. Cable sheath PVC. Version Compact sensor and plug design. Flat connector, 8pole, 1x pin. Connection cable, 6wire, ø 3.55–0.3 mm. Cable bend radius, > 17 mm (static). Note Works with magnetic tapes 21725. The reading distance between the sensor and tape must be 0.1 to 2 mm. The sensor is supplied with operating voltage and draws current via the electronics. System accuracy, repeat accuracy and travel speed is dependent on the electronics. Plugin connection to position indicators 21700 and 21702. Technical data Rating IP 67; EN 60529 (sensor head) Shock resistance 2000 m/s², 11 ms; EN 60068227 Vibration resistance 200 m/s², 50 Hz–2 kHz; EN 6006826 Temperature range Ambient temperature 0…60°C Storage temperature 10…70°C Assembly Installation must be carried out using the enclosed user information. A, reading distance sensor/tape ≤ 2 mm B, lateral offset ± 2 mm C, misalignment ± 3° D, pitch gradient ± 1° E, lateral gradient ± 3°

Request for a quote

NORELEM FRANCE

France

Right or left mounting with 90° closing. The quarter-turn lock can be installed pre-assembled (limitations by a small A-dimension and thick doors). The fastening nut has claws allowing it to be used as an earthing nut. Water and dust proof as per IP65 through the O-ring and flat seal. The lockable quarter-turn locks are supplied with 2 keys. The key can be removed in both positions (open and closed). The cylinder locks have a single-key system, i.e. the same key works in all locks (lock type 101 or 1333). Order required tongue version separately. Every tongue can be combined with every housing.

Request for a quote

NORELEM FRANCE

France

This quarter-turn lock is vibration-resistant through a detent mechanism in the end position. Right or left mounting with 90° closing and internal rotation limit. The quarter-turn lock can be installed pre-assembled (limitations by small A-dimensions and thick doors). Tested according to DIN EN 60068-2-64 (vibration) and DIN EN 60068-2-27 (shock), test standard 61373. Vibration-proof as per rail applications category 1, class B requirements (highest requirement). Water and dust proof as per IP65 through O-ring and flat seal. Order the required tongue version separately. Every tongue can be combined with every housing. Accessory: Lock key 05586 Drawing reference: Actuation: a) square 6 mm b) slot c) triangle 6,5 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical joint system, you will save time and optimize your production downtime by reducing the repair time. The mechanical assembly of ERO Joint® round belts is substantially better compared to another mechanical joint system. There is no other mechanical joint system in round belts with traction cord. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® round belts are spliced in our production using a patented process and fitted with the length requested. Anyway using ERO Joint® round belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® round belts are easy to assemble. Alternatives Hollow round belt with fastening system Hollow round belt with connector are only used for very low mechanical resistance.

Request for a quote

ERO JOINT .TANALS

France

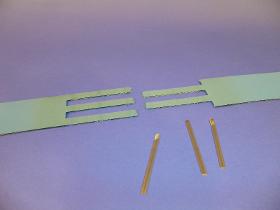

The mechanical fastening system ERO Joint® is available in flat belts with a thickness over 1mm containing an intermediate layer of Polyurethane. The assembly is made by threading of 3 transversal pins. Anyway using ERO Joint® flat belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® flat belts are easy to assemble. Advantages are a fast and easy installation and assembly. With this new lacing technology, you will save time and optimize your production downtime by reducing the repair time.

Request for a quote

ERO JOINT .TANALS

France

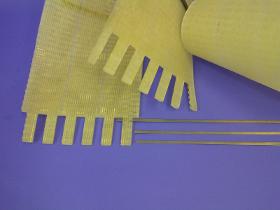

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. Mechanical splicing system ERO Joint® are also possible in conveyor belts with sealed tension members (like Gates PosiClean® and FlatClean FC12™) ->More about PosiClean® ERO Joint® belt The ERO Joint® conveyor belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

ERO JOINT .TANALS

France

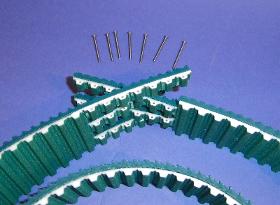

The mechanical fastening system ERO Joint® is available on pitches T10, AT10, T20, AT20, 8M, 14M for all widths over 16mm with reinforcement Steel, Kevlar or Stainless steel. (The recommended minimum diameter for pulleys is 50mm). The ERO Joint® splice is compatible with all type of coatings (Supergrip, Linatex®, PU, Sylomer®, …) and all types of guiding. ADVANTAGES Advantages are a fast and easy installation and assembly. With the pin mechanical fastening system ERO Joint®, you will optimize your production downtime by reducing the repair time. The assembly can be realized by screwing or with a tool. This tool enables the pre-tension of belt and makes pins threading easier. ERO Joint ® Ultimate version In Ultimate version, the mechanical belt fastener ERO Joint® transmits more than 50% of the power of a Flexbelt (true endless belt): Between pulleys, there is always a ½ continuous tight side to assure the mechanical resistance and the rigidity of the belt.

Request for a quote

ERO JOINT .TANALS

France

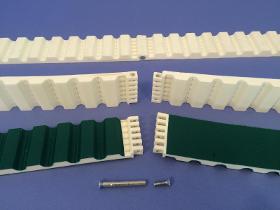

Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The recommended minimum diameter for pulleys is 50mm. The mechanical joint system ERO Joint® WT is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® WT are lasting solutions. The ERO Joint® WT splice shape may be adapted in order to increase the mechanical resistance. ERO Joint® WT is the only one solution of mechanical belt fasteners in wide timing belts. The ERO Joint® WT wide timing belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With the hinge pin mechanical fastening system ERO Joint® HP, you will optimize your production downtime by reducing the repair time. Mechanical strength and lifetime are higher than any other mechanical fastening systems. Mechanical resistance and elongation are equivalent to welded belts. TENSIONING TOOL FOR ERO JOINT® HP Alternatives Spiral seams The mechanical spiral seams system is also very easy to assemble as ERO Joint® HP but its mechanical resistance is poor. Pin Joint The mechanical Pin Joint system is more difficult to assemble than ERO Joint® HP. The mechanical resistance is also lesser than ERO Joint® HP.

Request for a quoteResults for

Assembly installations - Import exportNumber of results

12 ProductsCountries

Company type