- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forming press

Results for

Forming press - Import export

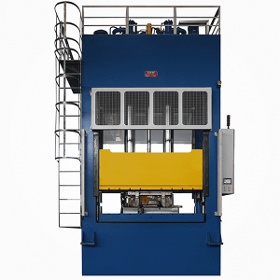

OZKOC HYDRAULIC MACHINE CO.

Turkey

In processes which requires single effect, Ozkoc offers variety of solutions between 70 to 7000 tons with extractors or complicated solutions with mold core in case of need. Please contact our specialists for choosing most suitable Hydraulic Press specifications for your production.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The O-forming press applies a press force of 4,000 metric tons per meter of pipe. This is necessary to form today’s material grades above X100 to the desired round shape at the optimum level of reduction. The control concept with (patented) multi-cylinder parallelism control ensures that the moving beam maintains a position parallel to the press table with a tolerance of +/-1 mm/m over the entire length. Combined with our tools, this results in a precise pipe gap which leads to signicant time and material savings for the subsequent welding process. The intelligent sensor and control concept of all main cylinders ensures that dierent sheet lengths (e.g., residual lengths) can be processed. The press is powered by either conventional drive concepts or via frequencycontrolled drive concepts. Our ECO Drive uses the high moving load of the moving beam to generate energy during the controlled quick lowering of the beam. This energy is fed back to the power network.

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Application areas for straightening presses include the sheet metal processing industry. Here, this type of press is used for the straightening of semi-nished products, such as the levelling of uneven sheet metal and slab surfaces, which are used in subsequent processes. In addition to high straightening accuracy, Siempelkamp straightening presses provide a broad straightening spectrum and high exibility in the further processing of sheet metal. For materials with a tensile strength of 1,300 N/mm2, sheet metal with a thickness of approx. 300 mm can be processed To do so, the presses are equipped with one or several straightening rams which can be operated together or individually. The pressing force needed for straightening is applied across the entire press width. Sheet metal can be straightened by cold or warm forming with sheet temperatures of up to 600°C.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our isothermal forging presses produce sophisticated, heavy-duty components for high-tech products. We furnish our customers with rst-class solutions including control systems for the ne-tuning of pressing speeds. Our presses are designed for high-precision applications indispensable in the aircraft/aerospace and medical engineering industries. The challenge here is to manage pressing speeds of 0.01 mm/s in controlled operation, which is ensured by our own electrical and hydraulic control engineering Siempelkamp also oers plants to be used for isothermal forging. They comprise the furnace, the feed manipulator, the forging press, the die heater, the hydraulic drive system and the entire automation technology. The plant control for isothermal forging presses monitors and documents the process parameters in compliance with the certication standards to be observed in the aircraft industry.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

As the leading provider of metal forming presses we are setting the standard worldwide. Our expertise in plant engineering and process technology is unique. This is because the individual performance features from the design to the startup of the equipment create a coherent and complete solution from a single source. Our hydraulic presses for metal forming are at home in cold and hot forming. From turbine disks for aircraft to pipeline pipes in the oil and gas industry to longitudinal beams in trucks: In our key industries of automotive, energy, rail and aerospace, we offer the right solution for every product. We supply not only the press, but also the associated process technology. Our range of services includes forging, thick sheet metal forming, raw forming, sheet metal forming and ring rolling. Our special systems for metal forming offer the perfect balance between the use of standard components and a custom-made design.

Request for a quote

PERGEL METAL

Turkey

CNC Press Brake puts the raw material that is in the form of metal or press into a new form by twisting it. It is a hair styling loom. In the old days, it was called caka, which was used more primitively in accordance with the possibilities. CNC Press decoiler bending machines are pressed between a mold to give a new shape. Hair is a metal loom. The lower and upper moldings are called male and female. In our company, cnc press brake is made of twist. A hydraulic pressure is applied. In press brake bending, the operation is performed by applying force. There are control panels that provide the principle of operation. Such characteristics of materials as their quality, type, thickness and pressure are also important.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

These bearings consist of a cage made from a steel plate, which is precisely press formed and surfacehardened, and needle rollers with a diameter variation within 2μm. They have a rigid structure and a high lubricantretaining capacity. As they have the lowest sectional height compared with other thrust bearings, they can be used instead of conventional thrust washers and can withstand highspeed rotations with a low coefficient of friction.

Request for a quote

NORELEM FRANCE

France

Body carbon steel. Ball, ball bearing steel 1.2067. Form D: Ball with POM insert. Form H: Ball with POM insert. Form K: Ball with carbide insert. Form M has a carbide ball. Version: Body tempered and phosphated. Ball hardened. Form M ball nickel plated. Note: Self-aligning pads serve as stops, supports and thrust pads in fixture constructions. Ball secured against rotation. * Valid only if the minimum bore depth is observed. Drawing reference: Form C: with male thread, flattened ball, smooth. Form D: with male thread, flattened ball, with POM insert. Form F: with male thread, flattened ball, diamond grip. Form M: with male thread, flattened ball, with carbide insert. Form G: press fit, flattened ball, smooth. Form H: press fit, flattened ball, with POM insert. Form J: press fit, flattened ball, diamond grip. Form K: press fit, flattened ball, with carbide insert.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). At PRUFREX, single-chamber and multi-chamber coils can also be achieved using two-wire windings. For specific magnetic flux requirements, we apply wires of different thicknesses to the coil form. Two different wire thicknesses, from 0.045 to 0.71 millimetres, on coil forms with press-in ferrite or metallic cores.

Request for a quote

NORELEM FRANCE

France

Form C and F: Ball steel, ball seat high-carbon steel. Form G and J: Ball high-carbon steel, ball seat steel. Version: Form C and F: Ball hardened and black oxidised, ball seat phosphated. Form G and J: Ball phosphated, ball seat hardened and black oxidised. Note: The self-aligning pads serve as stops, rests and thrust pads in fixture construction. The seating face returns to the start position when the load is removed. Ball secured against rotation. Drawing reference: Form C: male thread, flattened ball, smooth Form F: male thread, flattened ball, diamond grip Form G: press fit, flattened ball, smooth Form J: press fit, flattened ball, diamond grip

Request for a quote

NORELEM FRANCE

France

Material: Housing thick steel plate. Tyres steel-wire reinforced elastic solid rubber. Wheel body welded steel. Version: Housing press formed. Reinforced fork, base plate and centre pin. Double ball bearing with hardened shells in the castor head. Precision ball bearings in the wheels. Note: These castors are particularly impact and shock proof and assure a high service life. Wheel axle bolted.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Advanz™ 6F – e170 is a heat treatable product developed for automotive skin sheet applications. This product is characterized by excellent formability and excellent hemming behavior. Novelis Advanz™ 6F – e170 is predominantly used for critical exterior closure panels, but may also be used for demanding inner applications. Typical areas of application are hood outers, door outers, fenders, deck lids and critical inners. This product offers best in class forming behavior during press forming and exhibits significantly improved hemming properties over standard outer sheet. All values listed are typical.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). We can wind onto any desired coil form using many different press-in ferrite and metallic cores. Multiple tap coils are also possible. Pins are automatically applied to the coil connections during the winding process, with wire drawing electrically controlled. Our winding machines handle single-chamber and multi-chamber coils with wire thicknesses from 0.045 to 0.71 millimetres.

Request for a quote

KONSONET

Lithuania

Cocoa liquor (also known as Cocoa mass) is the basic ingredient in manufacture of all chocolate. It is the first product in liquid form which comes from pressing of the cocoa nibs. Cocoa liquor is the source of both Cocoa butter and Cocoa powder. After fermentation, cocoa beans goes under high heating process, by means of a Micronizer, which causes the shell to be separated from the nib. Thereafter the cocoa beans are broken and a winnowing machine is used to remove the shell thus collecting only the cocoa nibs. After roasting, the nibs are ground and processed into cocoa liquor.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

RPWORLD

China

Stamping is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the sheet metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging and coining etc. What Are the Manufacturing Processes of Stamping? Bending - the sheet metal is deformed or bent along a straight line. Flanging - the sheet metal is bent along a curved line. Embossing - the sheet metal is stretched into a shallow depression. Used primarily for adding decorative patterns.

Request for a quote

FERPLAST SNC

Italy

PNEUMATIC SEALER SM 35/40A - WITH DATE PUNCHER Pneumatic sealer SM 35/40 A for closing bags in any material using an aluminum plate with a height of 5/7 mm. All parts in contact are made of AISI 304 stainless steel suitable for contact with food. The seal is obtained from a coil with high autonomy, cut to a length of 35/40 mm, wrapped around the neck of the bag and finally pressed to form a flat closure. Machine complete with date and a kit of numerical punches, practical, economical and safe.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Material: Housing steel plate. Wheels with thermoplastic rubber tread. Wheel body polypropylene. Version: Housing press formed. Double ball bearing in the castor head. Plain bearing in wheels. Note: Wheel axle threaded. Swivel and fixed castors with bolt hole. Electrically conductive wheels, non-marking grey. The ohmic resistance of the wheel is less than 10⁴Ω. Application: Electrically conductive wheels on swivel and fixed castors are used to protect against electrostatic discharge generated by transport equipment or the transported goods. Damage to sensitive goods and painful electrostatic shocks to the personal is so prevented.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

The GESIPA® TRI-FOLD® blind rivet forms three press lashes on the closing head side during setting. The advantages The large moulded lashes distribute the exerted clamping force evenly and gently onto the riveted material. Also, the large surface of the lashes offer excellent protection against the rivet being pulled through very soft, porous or brittle application parts. Thanks to its special design, the TRI-FOLD® is also able to compensate over-dimensional or irregular drill hole diameters. Application areas TRI-FOLD® blind rivets are excellently suited for the automotive field, e.g. for plastic panelling, car body parts and for the interior work inside vehicles, but also for all other applications that are particularly soft, brittle, easily deformed or porous.

Request for a quote

TEKNIK KONTEYNER - WASTE BINS

Turkey

Our metal galvanized waste containers can be specially produced in line with the technical specifications of the product. It can be produced as hot dip galvanized or original galvanized. It can be produced with and without pedal options. Apart from 770 liters, it can also be produced in 770 liters, 660 liters and 400 liters capacities.Body 1.50 mm. It is formed by bending and pressing as a single piece of sheet metal and its strength is increased. Base corners are radiused. The assembly of the body sheet and the side sheets together, the 20.00 mm. formed by pressing the sides of the side sheets. It is mounted from the outside to the body sheet with a bent protrusion or lip in width and welded completely, including the radii, without interruption.Body welding and other welds were welded without slag by gas metal arc technique.The body mouth is completely surrounded by a pipe profile.

Request for a quote

TEKNIK KONTEYNER - WASTE BINS

Turkey

770 Liter Hot Dip Galvanized Waste Container (Dome Lid Model)Body 1.50 mm. It is formed by bending and pressing as a single piece of sheet metal and its strength is increased. Base corners have radius. The assembly of the body sheet and side sheets is made by pressing 20.00 mm on the edges of the side sheets. It is mounted externally to the body sheet with a wide bent protrusion or lip and is completely welded, including the radii, without interruption.The body weld and other welds were welded without slag using the gas arc technique.The body mouth is completely surrounded by a pipe profile.Lift arms and cover connection 2.50 mm. It is welded onto the sheet metal apparatus and screwed onto the body.Lift arms are manufactured in accordance with EN standards. Cover arms 3.00 mm. is.Cover 1.40 mm. It is manufactured from sheet metal as a system that can be opened around its own axis.

Request for a quote

TEKNIK KONTEYNER - WASTE BINS

Turkey

Our metal galvanized waste containers can be specially produced in line with the technical specifications of the product. It can be produced as hot dip galvanized or original galvanized. It can be produced with and without pedal options. Apart from 660 liters, it can also be produced in 770 liters, 660 liters and 400 liters capacities.Body 2.00 mm. It is formed by bending and pressing as a single piece of sheet metal and its strength is increased. The base has corners and the upper posterior rim is radiused. The assembly of the side sheets made of the same sheet with the body sheet, at least 15.00 mm. wide bent protrusion or lip including all perimeters and radii, with this protrusion, side sheets and body sheet, including external radii, are joined seamlessly by welding.The body welding and other welds are made by using the gas metal arc technique, without slag, by continuous boiling and the body is watertight.

Request for a quote

TEKNIK KONTEYNER - WASTE BINS

Turkey

Our metal galvanized waste containers can be specially produced in line with the technical specifications of the product. It can be produced as hot dip galvanized or original galvanized. It can be produced with and without pedal options. Apart from 400 liters, it can also be produced in 770 liters, 660 liters and 400 liters capacities. Cover lid color can be in different options.Body 2.00 mm. It is formed by bending and pressing as a single piece of sheet metal and its strength is increased. The base has corners and the upper posterior rim is radiused. The assembly of the side sheets made of the same sheet with the body sheet, at least 15.00 mm. wide bent protrusion or lip including all perimeters and radii, with this protrusion, side sheets and body sheet, including external radii, are joined seamlessly by welding.The body welding and other welds are made by using the gas metal arc technique, without slag, by continuous boiling and the body is watertight.

Request for a quote

KRANAMAX

Bulgaria

Presses: Our innovative presses are designed for high productivity and precision in metal processing, meeting the strict standards of the industry.

Request for a quote

KRANAMAX

Bulgaria

Presses: Our innovative presses are designed for high productivity and precision in metal processing, meeting the strict standards of the industry.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Chain conveyors made to handle severe-duty, highly abrasive, metal chips, fines and swarf. Transfer and elevate the most difficult and abrasive wet or dry metal chips, fines, swarf, die scrap and other materials with this rugged, chain driven, liquid-tight conveyor. Every part of this rugged chain driven conveyor is designed for severe duty. The Heavy-duty, abrasion-resistant flight bars of the scrap conveyor feature an exclusive bolt-free connection so they stay strong under grueling conditions. The abrasion-resistant steel press-formed trough is liquid tight and comes standard with safety covers

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA can improve material proportion and complete solution according to industry demand to achieve the best effect of customer use. Boron Nitride Ceramic Rod Characteristics: High thermal conductivity, pressed into various forms, used as high temperature, high pressure, insulation, heat dissipation components, such as aircraft, rocket engine nozzles. 2. Excellent thermal shock resistance and erosion resistance. It is used in Amorphous Ribbon Making and amorphous nozzles, three-dimensional printing metal powder diversion tubes, nozzles, etc. 3. High strength non-sticking, applied to various hot-pressing dies.

Request for a quote

TECHNIC MACHINES

Turkey

Scaffolding making machine line is the machine line, which for production of scaffolded metal boards for construction industry. Scaffolding Machine Line General Units Decoiler Straightener and Feeder Eccentric Press Roll Form Unit Stacking Unit For high speed scaffolding panel production results and for matching with our customers scaffolding panel design, we use continuously scaffolding roll forming machine on our scaffolding machine line. On roll forming unit, station quantity and rollform roller diameters are designed according to our customer’s scaffold board design. The scaffolding roll forming unit will be designed for having the best results. Also our eccentric presses have all necessary capabilities and can do precision work during scaffold production. It will work synchronized with other scaffolding machine line units.

Request for a quote

TECHNIC MACHINES

Turkey

We provide for our customers different combinations of cable tray roll former machine line. Such as feeding system solutions from coil or sheet or different working parameters for cable tray roll forming machine. And also we produce our cable tray production line with different final cable tray design as to customer's request. With different cable tray width, thickness, height or with different cable tray punching solutions according to our customer’s final cable tray design. Cable Tray Roll Forming Line Units – Cable Tray Press Feeding Unit – Cable Tray Punching Unit – Cable Tray Roll Forming Unit – Cable Tray Cutting Unit – Cable Tray Coupling Unit Solutions for Cable Tray Making Machine Cable Trays have no standard sizes. Sizes can be between 50 – 1200 mm width and can be between 25 – 100 mm flange height. - Light Duty Cable Tray Roll Former - Medium Duty Cable Tray Roll Forming Line - Heavy Duty – Cable Tray Production Line

Request for a quoteResults for

Forming press - Import exportNumber of results

82 ProductsCountries

Category

- Thermoforming, plastics - machinery (14)

- Metal industrial presses (10)

- Forming - steels and metals (7)

- Dustbins, waste bins (4)

- Mattresses (4)

- Presses, hydraulic (3)

- Wheels, castors and rollers (3)

- Coil winders (2)

- Electrical & Electronic Components (2)

- Screws (2)

- Bearings - ball, needle and roller (1)

- Bending - steels and metals (1)

- Boxes, cardboard (1)

- Brakes, servo-brakes and accessories (1)

- Cars - electrical and electronic parts and components (1)

- Ceramics, industrial (1)

- Cocoa and chocolate (1)

- Components and parts for small household appliances (1)

- Goods handling systems, continuous (1)

- Hydraulic equipment (1)