- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forging parts

Results for

Forging parts - Import export

MAROVT D.O.O.

Slovenia

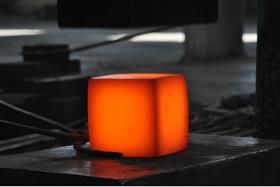

Precision forged parts are forged parts where very narrow tolerance can be achieved by following the forging process permanently. Our processes enable forging with the +/- 0.1mm tolerance. We are specialized in the production of precision forged parts weighing between 0.001kg and 1kg made of different material. The advantage of precision forged parts is that they can be used mostly in different compounds and without additional mechanical machining. Hot die drop forging is the method in our company – sticks are heated and inserted into the appropriate forging tool.After the forging process, we trim and pierce the semi-finished products to meet many shapes and other requirements. We shape stainless, alloy and carbon steels. In most cases, more complex and larger forgings are further machined.Due to the specificity of precision forgings, we provide the minimum necessary additional machining and thus reduce the machining times.

Request for a quote

MAROVT D.O.O.

Slovenia

different kind of forging products incl. machining

Request for a quote

NOVELTY STEEL

Turkey

Forging is a manufacturing process where metals and alloys are shaped into desired forms through the application of repeated blows from a hammer. This process is typically performed at high temperatures (hot forging), although some forging operations can be done at room temperature (cold forging) Typical forging applications are; Gears Flanges Crankshafts Connecting Rods Axles Shafts Bolts and Nuts Hooks and Shackles Valve Bodies Levers and Handles Chains and Sprockets Hand Tools Railroad Components

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: Carbon steel:S355J2G3, 40Cr, 40CrMo Stainless steel: SS316 Process: Die forging, Open die forging Application: Wind turbine, Construction equipment

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg have a freind factory which specialize in Hot forging services, we can outsourcing the rough parts from hot forged parts, then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. The hot forging process can produce steel products of all sizes and shapes,the forged parts have higher density and strength and are suitable for the production of various valve and pipe fittings,such as flanges, rings... We can forge stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials. If you have any parts suit for hot forging process, welcome contact with us to check it.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg as a professional metal parts supplier, specialize in Hot forging services, we can produce small hot forged parts by ourself and outsource the big hot forged parts as blanks then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. Forging refers to the process of forging and pressing metal objects in a red hot state with air hammers or presses (die stamping machine). Forging is to bake and knead the metal of the object into a shape. Nowdways, we use a high-frequency heater to heat the metal object to a red state within a few seconds, and then put it into the mold cavity for compression molding. We can produce forged parts from stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Brass Forging Parts is a metal alloy that consists primarily of copper and zinc. The mechanical properties of brass depend on percentage of zinc along with several additional elements, which can vary significantly. Brass is harder and has a lower melting point than copper, but it has excellent working properties and is excellent for many end usesOrdering brass bar stock to the specified alloy composition in one of the many forms and shapes available is the typical first step in the process. Saw cutting provides blanks, sometimes called slugs, that then enter the forging or forming process. Some grades of brass alloy may be processed at room temperature, but it is most common for slugs to be heated to improve formability. Temperature for hot forging is usually in excess of 1000 degrees F but both the alloy and complexity of the configuration will determine the exact process requirements. In the forging process, the cut slugs are placed between dies and force

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

OEM Forging Auto Parts OEM Forging Auto Parts Manufacturer Process precision forging+ blasting+ cnc machining (https//www.frimaparts.com/precisionmachiningparts2/) Material Aluminum , Brass (https//www.frimaparts.com/brassforgingparts/) , carbon steel, stainless steel, iron Machining turning, milling, drilling, grinding, threading, CNC Finishing sand blasting, polishing, plating, acid treatment, anodizing, coating Design customized samples or drawings are accepted Weight range 0.1100KG Packaging paper carton + bubble bag Delivery time tooling/sample within 4 weeks, batch order within 4 weeks. Inspection all the products are strictly inspected by QC. We develop custom products for clients all over the world, such as 3D Robotics, Nvidia, Smart Systems and so on. We are experienced in many processes, such as stamping (deep drawing, bending), cutting (pipe cutting, profile cutting,

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Cold Foging Parts Suppliers, Custom forging parts,weld nuts,weld washers,square nuts,nonstandard bolts,studs. Ming Xiao Metal Parts Manufacturing custom produce cold forging parts(such as bolt,nuts,screw,metal pin,metal stud) according to customer’s drawing or sample, we made nonstandard fasteners by cold heading / cold forging or lathing – handle pins, Dowel Pins, nonstandard hex head bolts,squre head bolt,philips head screws,pan head screws,nonstandard screws, nonstandard pins, nonstandard nuts of square nuts,self lock nut,all kinds of metal studs,etc. Generally we use cold forging process to produce rough parts, then machining it again by turning,milling and other machining processes to make the parts with good surface and dimensions.This way can make the production cost reduced and the producing processes more less.it’s a more competitive way to produce high quantity parts. If you need any parts produced by cold forging process, pls don't hesitate to contact us.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg have a freind factory which specialize in Hot forging services, we can outsourcing the rough parts from hot forged parts, then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. The hot forging process can produce steel products of all sizes and shapes,the forged parts have higher density and strength and are suitable for the production of various valve and pipe fittings,such as flanges, rings... We can forge stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials. If you have any parts suit for hot forging process, welcome contact with us to check it.

Request for a quote

MODULUS METAL

Turkey

Hot Open Die Forging Hot Closed Die Forging Cold Closed Die Forging Cold Heading and Upsetting Cold Shape Rolling Hot Shape Rolling Swaging

Request for a quote

FORJA NEPTUN SRL

Romania

FORJA NEPTUN has the capability to produce forged parts from carbon steel, alloy steel and high alloy steel, as well as rough or final machining on forged blanks/ parts.

Request for a quote

DONLOUCO IRELAND LTD

Ireland

Donlouco has extensive experience in forging of hydraulic components, Cylinder bases, Flanged components and Rod eye. Part weights from 0.5Kg to 50Kg. Max forging capacity: 1,600 Ton. Forged parts for the hydraulics industry with secondary CNC Milling & Turning Forging capability from small detailed parts to large forgings of 50Kg. Maximum forging capacity of 1600 Ton. Forged parts mostly CNC machine to finished part level. Forging tools designed and managed and can be reversed engineered from finished part drawings by Donlouco. All steel grades to meet customer requirements and European standards. Forged parts can be fully tested, tensile, impact etc at approval stage and by sampling as required. All parts fully checked and inspected before shipping with full traceability and reports available with all shipments.

Request for a quote

MAROVT D.O.O.

Slovenia

The advantage of the Marovt company is that forged parts are machined in our own forge. This is why we are able to ensure forged parts with characteristics defined together. The machining of forged parts is mostly automated; therefore, the human factor is decreased and permanently the same technological process can assure all parts to be machined in the same way and being controlled and tested according to the same procedures.The machining of forged parts is carried out on technologically advanced 3 and 4-axe machines. Our machining centres have the possibility of using up to 40 changeable cutting tools. The tool can be up to 300 mm long and up to 10 kg heavy.The machining center spindle can rotate up to 20,000 rpm. Changing the cutting tool at our centers only takes 1.7 s, which greatly shortens the machining time. All our machining centers have a pallet system that eliminates the time of mounting the forging parts into the clamping device.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg have a freind factory which specialize in Hot forging services, we can outsourcing the rough parts from hot forged parts, then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. The hot forging process can produce steel products of all sizes and shapes,the forged parts have higher density and strength and are suitable for the production of various valve and pipe fittings,such as flanges, rings... We can forge stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials. If you have any parts suit for hot forging process, welcome contact with us to check it.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Drop-forgings of carbon and alloyed steel, nickel, duplex, titanium and superalloys like Monel® or Hastelloy®, Inconel®, Incoloy® for pressurized components like forged valves or valve parts like bodies and yokes or bonnets, flanges for boiler systems, fittings for piping, non-corroding parts for shipbuilding, marine technology, slings and lifting gear, hooks, eyebolts, nuts, chain links, military vehicles, transportation and defense. Every nut, bolt, and screw - forgings for harsh environments: forged valve bodies, bonnets, yokes and flanges, pipe connections, pressure applications like boiler parts, hoists, chain links, eyebolts, hydraulic components, corrosion and acid-resistant parts for chemical and fertilizer industries, as well as shipbuilding and drill equipment. Pressure equipment and nuclear power (valves, boilers, piping): PED 2014/68/EU, AD 2000-W0, ASME/ASTM, KTA, RCC-M Shipbuilding and maritime industry ABS, BV Marine & Offshore, DNV, LR Shipping, ClassNK

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAROVT D.O.O.

Slovenia

With knowledge gained in past years we can provide you with a complete solution – from the idea to the final product. We cooperate with customers from the beginning, from the idea and this is how we contribute to faster solutions in the field of implementation of forged parts into the final system.Modern software and highly skilled employees are keys for the good-quality, fast and expert construction of complete tools and compounds.To design and program machines we use Siemens NX and Visi Vero software, which enable us to read and write data in several possible formsNX files, Solid Works files, IGES, PARASOLID, STEP, SXF, DWGBy using conversion modules, we can also open and saveCATIA, Pro / E, Inventor and STLTo achieve the shortest possible time from development to final products, we use modern software for simulating forging. We have a QForm product in use, a synonym for forging simulations.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Hot forging and CNC machining Brass parts

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Forged parts made of steel, stainless steel and aluminum including mechanical processing. Pressed brass blanks including mechanical processing, also on rotary transfer machines. Sintered parts made of sintered bronze, sintered porous brass and stainless steel. Filter elements for air, liquids and fuel made of sintered ball material or mesh.

Request for a quote

CMPLAST

Poland

It is characterized by good susceptibility to machining. It is very susceptible to hot forming and forging. It is widely used in the production of forged parts with complicated shapes parts for pipe fittings industrial terminals heating elements plumbing industrial fittings We also have other nonferrous materials on sale.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

HT spur gear bevel gear spiral gear Steel quench and tempered, bronze etc. Custom made according drawing With our specialized expertise in custom gear, gear shaft, castings parts, forging parts, machined parts, welding parts for almost three decades, we can assist you on your industrial development. Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We are proud of our core competence in industry leading production processes, spectrometer analysis, critical NDT and tight tolerance machining.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-Tai has been specialized in Custom High Precision Gear, Gearbox, Gear shaft, Castings, forgings, machining parts, metal stamping parts and assembly since 1996. Material options are steel, aluminum, bronze, iron etc. We strive to provide the high quality castings and try to avoid defects delivered to our customers. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Special inspection method agreed by customers like hydraulic, gas tight test, water tight test etc.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-Tai has been specialized in Custom High Precision Gear, Gearbox, Gear shaft, Castings, forgings, machining parts, metal stamping parts and assembly since 1996. Material options are steel, aluminum, bronze, iron etc. We strive to provide the high quality castings and try to avoid defects delivered to our customers. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Special inspection method agreed by customers like hydraulic, gas tight test, water tight test etc.

Request for a quote

ANKARA BRONZ

Turkey

ECU 99,9 % : Electrolytic is used as copper material with a conductivity of 58, electrode in erosion, high-low current panel and busbar in substations. Among our standard products: Rod, Sheet Plate, Straight pipe, Tube Coil, Box profile, Grounding rod - plate, Roofing, Copper fittings and thin wires. Also, sheet plate measurements which do not have a standard are brought to necessary measurement by forging at desired dimensions. Parts that require CU-Cr-Zr (Chromium alloy) High electricity conductivity, hardness and strength at high temperatures: Are used as point welding electrode and seam welding disc at the source of low carbon steels (Panel radiator, Gasoline warehouse, etc.) and Galvanized steel plate (Automotive and white goods), electrode holder at spot welding machines, plunger electrode at erosion machines and contact busbar at substations.

Request for a quote

EXTRA FORGE D.O.O.

Slovenia

At our company, we offer comprehensive heat treatment services for both steel and aluminum products. Our team consists of expert associates who are leaders in their respective fields, ensuring top-notch quality and precision in every project. Additionally, we provide valuable consultation to help you determine the best available options or optimize processes to achieve your desired results efficiently.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Machine Parts manufacuring more than 20years, we have all kinds of machining equipment, can provide a variety of processing methods to meet the machining of various steel parts. As a professional Steel Machined Parts supplier from China,we can custom producing all kinds Carbon & Stainless steel turned parts,Copper & Brass turned parts,Aluminum Turned Parts & Machined parts, such as tube coupling, hose coupling, shaft, pipe joint parts, hose connectors & transition connectors, copper machined tube, flange,bushing, knighthead, pedestal, Piston Rod, insert long pin, Dowel Pin, Drive Pin & Rod,ball head bolt, long rod machined parts, long thread tube parts, nonstandard thread bolt & nut,Extension Rod, etc. Widely use for all industries. China Metal Parts manufacturer custom produce Steel Machined Parts according to customer’s design, provide CNC Turning, Milling, Tool Machining Services, Welcome send inquiry to us !

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Gears are mechanical components and an essential part of many machines and are used in everything from piston engines to gearbox construction to agricultural machinery and wind turbines. Here are some of the main gear types: Spur and Pinion Gears: These gears have straight teeth and are the most common. They transmit rotational movements parallel to the axis and are found in gears, clocks and machines. Bevel Gears: These gears have tapered teeth and movement between non-parallel axes. They are used in differential gears of vehicles and in industrial machinery. Worm Gear: This combination of worm and worm wheel provides high gear ratio and is used in hoists, conveyors and other applications. Hydraulic The West German drop forge KB Schmiedetechnik GmbH produces forged gear blanks, piston parts and hydraulic components for a wide range of applications - from agricultural machinery and conveyor technology to engine construction, diesel generators to shipbuilding. ISO 9.001 + 14.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg as a experienced Steel Parts CNC turning source factory customized many steel parts according to customer's designs, quality always good and price lower than others. We have many different type turning machines, automatic turning machines, and CNC turning machines,Swiss CNC turning lathe, Turn & Mill Composite machining Machine, 3,4,5 axis CNC machining centers. We also equiped cold forging & hot forming production line, can produce blanks for our steel turned parts, greatly reduce the material cost, improve the processing speed and cost, improve the quality of the workpiece. According to quantity & precision requirement, optimize the turning processes to make the machining cost to be lowest. We produce turned parts from raw materials of bars,tubes,forged blanks,casting.,According to the number of parts, structure and other factors, choose the most economical and reliable blanks.saving cost improve quality.

Request for a quoteResults for

Forging parts - Import exportNumber of results

71 ProductsCountries

Company type

Category

- Machine tools, metal machining - parts and accessories (8)

- Forming - steels and metals (5)

- SMALL METAL PARTS (5)

- Forges - machinery and installations (3)

- Gears (3)

- Metallurgy - machinery and installations (3)

- Shaping - steels and metals (3)

- Brass (2)

- Cylinders, hydraulic (2)

- Sharpening - steels and metals (2)

- Steels and metals - machining (2)

- Turning - steels and metals (2)

- Automobiles (1)

- Bronzing - steel and metals (1)

- Casting, steel (1)

- Copper and copper alloys (1)

- Fasteners, metal (1)

- Flanges (1)

- Fossil fuel power stations (1)

- Foundries - copper, bronze and brass (1)