- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- food industry waste

Results for

Food industry waste - Import export

BASE GROUP SP Z O.O.

Poland

We have been successfully welding of constructions for waste and constructions for food industry for many years. The structures for waste are welded of steel of different sizes and weight. We manufacture high quality steel constructions for waste or food industry, which are customized to our customers’ needs and in accordance with the international standards ISO 3834-2, ISO 9001:2015 and ISO 14001:2004 and EN 1090-2.

Request for a quote

EUROPEM

Belgium

Enclosed ground flares are suitable for thermal destruction of a wide range of waste gases including rich and lean gas mixtures. Where the burners are housed in a cylindrical vessel resulting in the combustion process being out of sight and more controllable in comparison to elevated flares. Enclosed ground flares can also be designed with or without temperature control. With temperature control, a minimum residence time, at a specific combustion temperature can be set and guaranteed. Consequently, temperature controlled ground flares, also called combustors or thermal oxidisers, can meet the most stringent emission values. The emissions can be monitored with chemical emission monitoring (CEM) units. Features Can be equipped with Europem’ proprietary Tulip Venturi Burner for the combustion of lean waste gases or with multiple burners designed for the flaring of large capacities (modulated flaring is possible) Operating at varying temperatures depending on the load of the ground flare Smokeless operation and high destruction efficiency by ensuring some turbulence around the flame and sufficient residence time at elevated temperatures Simple control system, because the combustion temperature is allowed to fluctuate Provisions for support fuel in cases of combustion of lean waste gases or cooling air in cases of rich waste gas combustion Can be supplied as natural draft or forced draft system Can be supplied with or without temperature control Advantages No visible flame and reduced visibility of the installation due to lower stack heights Reduced noise levels Minimal heat radiation Possibility for emissions sampling High destruction efficiencies and smokeless operation Applications Tank farms and ship loading terminals Chemical and petrochemical industries Food processing industry Waste management plants

Request for a quote

EUROPEM

Belgium

Utility Flares (Pipe Flares) are the most basic flare design available, to provide a robust, reliable and flexible solution for the flaring of large volumes of low pressure waste gas when smokeless operation is either not required or can be achieved without an assisting medium (like steam, air or gas). Reliable operation at both full load and partial load is possible. Key features Flame holders fitted on the periphery of the flare tip ensure stable operation. These flame holders provide a zone of recirculated flue gases, which prevent flame lift off, from the flare tip. Wind deflectors to prevent flame impingement, which prevent a low pressure zone, downwind of the tip. Pilot burner arrangement to further stabilise the flame. Use of high grade alloys to enhance lifetime of the flare tip Use of dynamic seal to reduce purge gas requirements and prevent flash back. Key advantages Low investment and operational costs Low maintenance costs with the use of high grade alloys and the robust design. Reliable and stable flaring in a wide range of operating conditions Large turn-down ratio Applications Upstream oil & gas sector LNG terminals and NG compression stations Chemical and petrochemical industries including refineries Food processing industries Municipal solid waste treatment (biogas and landfill gas) plants Temperature controlled combustors and thermal oxidisers.

Request for a quote

REINASAN BV

Netherlands

With this animation, we try to give a brief and clear explanation of our system for the food industry in a playful way. More details on this and possibly other Reinasan systems can be found here on Europages, our website and on our YouTube channel. We'd love to hear from you! Feel free to send us a message via this platform. Have fun watching!

Request for a quote

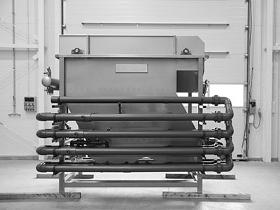

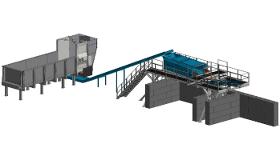

CARBOMECH SP. Z O.O.

Poland

We offer design and construction services for waste processing lines. Our technological solutions are developed with the aim of ensuring maximum efficiency, full automation, and the highest level of operational safety. The presented waste processing line consists of a set of machines, including a container with a shredder, belt conveyors, and a rotary screen. These components are assembled and controlled in such a way that they operate as an integrated whole. The control system ensures the operation of the entire set in both automatic and local modes. Production on the technological line is only possible in automatic mode. Operation in local mode is permissible only during maintenance work. The control system allows for smooth regulation of the line speed.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAKERMAN CORP.

Turkey

Eco-friendly Chemical & Biological Decontamination of Medical Effluent Water and Dangerous Liquid for Contaminated laboratory waste infectious fluids blood and blood products Dialysis fluid waste Liquid pathological waste Pharmaceutical waste and dangerous chemicals. Chemical Neutralization and Biological Treatment Stainless Steel Reactor Tank Biological UV Treatment Disinfection with Ozone

Request for a quote

GEYZER (KZKO LLC)

Russia

To dispose of waste is more and more a cost factor. Every industrial company produces a lot of general and municipal waste. With a license and an incinerator, you have a way to handle your waste problem. Be sure, incinerate municipal rubbish is an ecological, cost-effective and easy solution. In which industrial companies it is very popular Construction companies Building Chemical companies Food industry Oil and gas industry Production of raw materials Plastic industry Every kind of wood industries CBD industry Pharmaceutical industry

Request for a quote

INTEGRATEDAIR SYSTEMS

United Kingdom

Wherever an industrial process produces waste, we can design systems to capture and remove it. The waste will then simply be taken away to be recycled or disposed of. Our expertise in this process is trusted for many different medias and industries such as food and beverage, paper, corrugated card or packaging and containers. Efficient industrial waste extraction in the workplace is critical to the safety of your working environment, and with over 100 years of combined engineering expertise behind us, we’re the ones to call.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Safety, performance and minimum maintenance costs are our focus. Years of close collaboration with machine manufacturers in food processing and packaging have allowed us to develop a full product line of premium, physically non-hazardous lubricants, that are neutral in odour and taste. Our synthetic greases and oils have been formulated to meet the performance requirements of your machines, even in the harshest environments.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Solid-free product range of high-temperature chain oils with InS/H1 food grade approval for the lubrication of conveyor chains. These products minimise lubricant consumption on conveyor chains in high-temperature ovens and dryers and prevent carbonised deposits.

Request for a quote

DC DI CANDIA RUOTE

Italy

The D-NAMIC wheels are manufactured through a new vacuum - dryer - high pressure process, entirely developed by DC, which results in the higher quality wheel in its range of products, and the only one to be covered by a lifetime warranty against the de-bonding of the Polyurethane tyre from the wheel centre. The Polyurethane tyre grant a high cut and tear propagation resistance, is mechanically bonded to the wheel core, and the coupling is further strengthened by a surface adhesion which is obtained without the use of any glue or chemical bonding. The D-NAMIC wheels can be fitted into a specific series of brackets for which are specifically studied and produced to fulfill the extremely wide variability of conditions to which they are submitted, for both industrial and food industry. D-NAMIC are recommended on trolleys for food industry and chemical industry, industrial trolleys, equipment and trolleys for meat and fish industry, slaughterhouses and textile industry.

Request for a quoteResults for

Food industry waste - Import exportNumber of results

12 ProductsCompany type