- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- folded paper towel machine

Results for

Folded paper towel machine - Import export

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA OS5 bag packer and packaging machine offers a new method for packaging tissue paper into either polyethylene bags or polyethylene film with the integration of reasonable product compression during the packaging process. The final packed product comes out as a nice, tight, compact package which is easy to palletize. Carton boxes for the secondary packaging are not needed anymore. The press capacity allows perfectly adapted product compression without any quality deficits. Due to the tight and compact film package, the number of truck loads required for transporting only the packaging material is significantly reduced as well as for the transport of the final package. Altogether, the new packaging method gives a high potential in cost saving on packaging material warehouse storage, shelf space and logisitcs and it is environtmentally friendly. Quick and easy change-over Premade polyethylene bags on wickets Carry-handle possible

BARTSCHER GMBH

Germany

Suitable for standard folding paper Interfold folding Layer folding Zig-zag folding

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Accumulator, the transfer machine is a device that plays an important role in the production processes of toilet paper and kitchen towel rolls, increasing the efficiency of production lines. This equipment automates the storage, sorting and dispatching of rolls, ensuring that the production process is uninterrupted and orderly. This device which is widely used in modern toilet paper production facilities, significantly increases the efficiency of the production line and product quality. The Roll/Log Accumulator is a device that transfers the produced rolls of toilet paper or kitchen towels to the next unit and regulates the flow in the production process. This accumulator is designed to prevent possible disruptions in the production line and to ensure a continuous production flow. It facilitates the organised processing and packaging of the rolls in the production process and allows the glue to dry before the rolls are cut to the desired size.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Combining aesthetics and functionality in toilet paper and kitchen roll production, the 5 Embossed Toilet Paper and Kitchen Roll Machine has a technology that gives extra softness and absorbency to paper products. The embossing process increases both, the visual and tactile quality of the product by adding embossed patterns to the paper surface. If high quality and standard are needed for toilet paper and kitchen rolls, this machine is ideal. The Toilet Paper and Kitchen Roll Machine with 5 Embossings is a production machine that adds special embossed patterns to paper products. This machine adds aesthetic and functional reliefs to the surface of toilet paper and kitchen rolls by using special embossing rollers. These embossings increase the paper’s softness and absorbency, thus improving the product quality. High Quality Embossing Process: it gives an aesthetic and tactile superiority to paper products.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

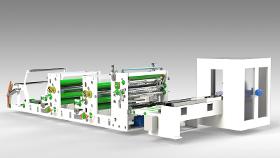

Automatic Mono Toilet Paper and Kitchen Towel Production Line is an efficiency and quality-oriented technology that realises toilet paper and kitchen towel production on a single line. This production line stands out with its high speed and continuous production capability in modern paper production processes. The ability to produce both toilet paper and kitchen towels on a single line simplifies production processes and increases productivity.Automatic Mono Toilet Paper and Kitchen Towel Production Line is a system that can produce both toilet paper and kitchen towels in a single production line. The main feature of this line is that it can produce both products at high quality standards and continuously. In this way, more production can be done in less space. Double Product Production on a Single Line: Both toilet paper and kitchen towel production. High Productivity: Continuous and fast production processes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

V-fold dispenser napkins, which are frequently used in modern restaurants, cafes and service sector, are produced with high efficiency and quality standards thanks to these machines. V Fold Dispenser Napkin Machine is a machine that packs paper napkins by folding them in a ‘V’ shape. This special folding method allows the napkins to be used easily in dispenser devices and allows them to be removed individually. The machine makes it possible to produce large quantities of napkins particularly quickly and efficiently. Folding Technique: Folds the napkins in a special 'V' shape. High Production Capacity: Suitable for the production of large quantities of napkins. Flexible Production Options: Ability to process master bobbins of different sizes and thicknesses. User Friendly Interface: Easy operation and adjustable functions

Request for a quote

ATLAS DIS TICARET

Turkey

Z FOLD PAPER HAND TOWEL 18 GSM X 2 PLY CASE OF: 200*12 = 2400 PCS 150*12= 1800 PCS 120*12=1440 PCS

Request for a quote

PAPERFOLDMACHINE

Italy

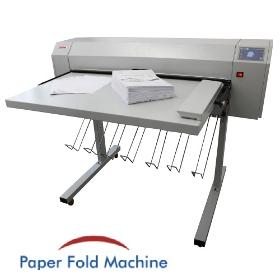

The paper folding machine PFM 222 is designed to fold drawing printed with any printer technology at low cost in only 5 seconds. This paper folding machine is able to fold any technical and architectural drawing perfectly to A4 fold package 210mm by 297mm metric standard or to the imperial A size 8.5×11 9×12 inches . The paper folding machine can process any plot dimension up to the width of 920mm and unlimited length. The type of document the folding machine can fold are colour maps and mechanical archictectural drawing , black & white line document and colour technical drawing.

Request for a quote

PAPERFOLDMACHINE

Italy

PFM 425 is an folding machine designed to fold with one sigle insertion blueprint large format documents. Folding machine concept: a large table that allows a constant flow of high-speed folding operation, fold precision, 3 different fold pattern with or without margin, last panel compensated . Usually off line blueprint machines requier to feed document twice to get the 1st fold process and then is required to feed it again to get the second fold process and reduce the blueprint document width, this allow to get directly A4 fold package in shorter time. The blueprint folding machine is extremely fast 25 meter per minute designed for reproshop and print rooms with high print output by diffrent printers. Maximum productivity, thanks to the large table designed to enable an uninterrupted workflow at 20 A0 / E-size / minute

Request for a quote

YENIADA FLEXO PRINTING MACHINERY

Turkey

Yeniada Makina’s folding machine , used to fold printed rolls into new roll Machine features: Working speed up to 150 meters per minutes Meter Counter Automated tension control system Airshaft roll holder 7″ touch control panel Edge control system Custom roll width design

Request for a quoteResults for

Folded paper towel machine - Import exportNumber of results

11 ProductsCountries

Company type

Category