- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flow sensors for liquids

Results for

Flow sensors for liquids - Import export

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The preeflow flowplus16 is a material-resistant, dead space-free miniature pressure sensor in the smallest design - for moving fluids. The "Luer-Lock" (male/female) on both sides makes it suitable for all common dosing systems that work with this type of thread. The sensor generates a standardized, compatible, linearized and temperature-compensated output signal. Existing dosing systems can be easily extended and protected with the pressure sensor. The flowscreen is a robust evaluation device for applications in various fields of application. In combination with the pressure sensor flowplus16, a complete system for fluid process monitoring is created. Thanks to standardized signals and standardized connections, the components can also be integrated as individual components. Your advantages: - Inline sensor - A pure flow sensor - Maintenance-free - Supply/voltage supply 24 V +- 10% - Mechanical Luerlock connection to DIN EN 1707

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE flow rate sensors for the flow rate detection of 1...10 l/min feature one-piece measuring tubes with an inner diameter of 4...10 mm from highly resistant stainless steel V4A (1.4571). For particularly aggressive media EGE offers special materials, such as bronze, Hastelloy, titanium or even PTFE. The devices can either be set up intuitively using a potentiometer and LED indications or easily programmed using buttons and a multi-segment display. EGE flow rate sensors can be installed in circuits with corresponding pipe diameters using threaded fittings or compression fittings. The provide excellent measuring results wherever the safe, robust and low-maintenance monitoring of low flows is required.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE flow rate sensors for the flow rate detection of 0...1 l/min feature one-piece measuring tubes with an inner diameter of 3.5 mm to 4 mm from highly resistant stainless steel V4A (1.4571). For particularly aggressive media EGE offers special materials, such as bronze, Hastelloy, titanium or even PTFE. The devices can either be set up intuitively using a potentiometer and LED indications or easily programmed using buttons and a multi-segment display. EGE flow rate sensors can be installed in hoses or circuits with small pipe diameters using threaded fittings or compression fittings. The provide excellent measuring results wherever the safe, robust and low-maintenance monitoring of low flows is required.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE flow rate sensors for the flow rate detection of 10...100 l/min feature one-piece measuring tubes with an inner diameter of 20 mm from highly resistant stainless steel V4A (1.4571). For particularly aggressive media EGE offers special materials, such as bronze, Hastelloy, titanium or even PTFE. The devices can either be set up intuitively using a potentiometer and LED indications or easily programmed using buttons and a multi-segment display. EGE flow rate sensors can be installed in circuits with corresponding pipe diameters using threaded fittings or compression fittings. The provide excellent measuring results wherever the safe, robust and low-maintenance monitoring of low flows is required.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG FS7.4W gas flow sensor has been developed for applications with temperatures up to 400 °C. The design of the FS7.4W is based on the FS7 design which offers a symmetrical heater that enhances sensitivity. The FS7.4W flow sensor is applicable in gas and offers excellent long-term stability. The small thermal mass of the FS7.4W sensor provides a fast response time. Further advantages of the FS7.4W thermal mass flow sensor include: — Easy adaptation in various applications and housings — Excellent long-term stability — Simple signal processing — Simple calibration — Stable platinum technology — Excellent reproducibility — Customer-specific sensor available upon request The IST AG FS7.4W flow sensors are optimal for measuring gas flow in various flow applications.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG FS7 thermal mass flow sensors are the successors of the FS5 flow sensors and exhibit a symmetrical heater design and enhanced sensitivity. The FS7 flow sensor is applicable in gas and offer excellent long-term stability. The small thermal mass of the FS7 sensor provides a fast response time. Additionally, the standard FS7 sensor is also available with a housing which is easily implemented into various applications. Further advantages of the FS7 thermal mass flow sensor include: — Easy adaptation in various applications and housings — Excellent long-term stability — Simple signal processing — Simple calibration — Stable platinum technology — Excellent reproducibility — Customer-specific sensor available upon request. The IST AG FS7 flow sensors are optimal for measuring gas flow in various flow applications.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG FS2 flow sensors are applicable in gas and offer excellent long-term stability. In addition to measuring flow rates, the FS2 gas flow sensor is able to detect flow direction with outstanding sensitivity. Further advantages of the FS2 thermal mass flow sensor include: — Simple signal processing — Simple calibration — Bare sensor resists up to +450 °C (customer specific) — Stable platinum technology — Excellent reproducibility — No moving mechanical parts — Customer-specific sensor available upon request The IST AG FS2 flow sensors are optimal for measuring gas flow and direction.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

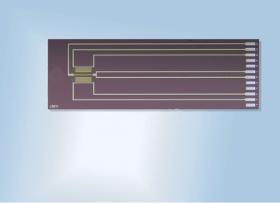

The IST AG MicroFlowSens (MFS) technology was developed for fast flow measurements. Due to the membrane system, the thermal mass is reduced to the minimum resulting in a very fast response time and low power consumption. In addition to measuring flow rates, the MicroFlowSens offers an outstanding sensitivity and is able to detect flow direction. The MFS flow sensor is optimal for limited space system integration and is available as integrated sensor on a PCB. Further advantages of the MFS thermal mass flow sensor include: — Excellent solution for applications with high flow rates and fast response time in CTA mode — Very high measuring dynamic with CTA mode (10'000'000 : 1) without bypass — Excellent for the measurement of very low flow rates and leakage detection with bridge mode — High chemical resistance against aggressive gases and vapors — Different sensitivities, circuit topologies available — Detection of flow direction — Customer-specific sensor layout upon request

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The SFS01 is particularly suitable for low flow velocities up to 3.5 m/s (in gases). It shows very fast measurement results of the flow rate as well as the flow direction. The Silicon Flow Sensor SFS01 offers three main characteristics: — Very fast response time <5 ms — Very low energy consumption — Easy system integration including temperature compensation Well-adapted channel geometries allow the performance of the sensor to be optimally aligned to the desired application. The SFS01 flow sensor is ideally suited for space-limited applications, but can also be easily upgraded to complete ready-to-use systems. Suitable application areas for the SFS01 flow sensor are flow measurements in battery-operated / portable devices, air conditioning technology (HVAC), automation technology as well as process and control engineering.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG SFS01 EvaKit offers an easy evaluation of the SFS01 gas flow sensor. It has both analog and digital output (I2C) and allows a fast and flexible evaluation of the SFS01 sensor. The I2C output includes both raw values and calibrated flow values from 0 to +-200 sccm. Further advantages of the SFS01 EvaKit include: — Excellent measuring dynamics — Analog output of raw signal — Digital output with raw signal and fully calibrated signal — Integrated flow channel with pneumatic connections

Request for a quote

FLUX-GERÄTE GMBH

Germany

FLUX flow meters constructed on the nutating disc principle (FMC), oval rotor (FMO) or the turbine principle (FMT), provide the right solution for every application. Depending on model and overall size they can be used on e.g. FLUX drum pumps or stationary e.g. in pipe lines. Using the digital display unit FLUXTRONIC® for FMC and FMO filling and metering processes can be carried out for virtually all liquids with maximum precision and the greatest possible safety. In automatic mode there is the possibility of transmitting signals for control purposes. In this way differing processes can be regulated.

Request for a quote

MICROCYBER

China

Parameters Basic Parameters Bus Power Supply: 9~32VDC Current consumption (static):≤14mA(FF/PA) 11V~35 VDC(HART) Input Signal: Pt100, Pt1000, Cu50, Cu100 Ω, 0, 0 to 500 ~ 4000 Ω Resistance, B, E, J, N, K, R, S, T eight degrees of Thermocouple, -100mV ~ 100mV Voltage Signal The Channel Number: Single Channel Fieldbus Protocol: FF/PA/HART Insulation: Between the Terminal and the Housing:500Vrms(707VDC) Operating Temperature: -40℃~85℃ Humidity Range: 0%~95%RH Starting Time: ≤5secs. Turnover Time: 0.5secs. Electromagnetic Compatibility: In Line with the GB/T 18268-2010 Explosion-Proof Sign: Ex ia IIC T4 Ga (HART)

Request for a quote

OMEGA AIR

Slovenia

Thermal mass flow sensor OS 401/OS421 is suitable for consumption measuring in different compressed air systems. The version with a display shows the volumetric flow and the total compressed air consumption. The keyboard enables setting of tube diameters and consumption counter. Various settings such as gas type, flow unit, reference standards, can also be set.

Request for a quote

OPTOLUTION MESSTECHNIK GMBH

Germany

Large heat and flow meters are often used continuously for decades after an initial calibration at external test benches. A recalibration of these meters within their actual operation conditions was not possible so far. In the best case scenario those flow meters are unmounted and recalibrated on an external test bench. Drawback of this method is an interruption of supply in addition to its already high costs. Furthermore, calibration conditions can differ greatly from actual operation conditions compared to test bench conditions, so even if calibrated, the measurement uncertainty in operation remains fairly unknown. This often leads to more difficult fluid distribution optimizations and leaves billing fairness to a gamble. More precisely measured values of flow sensors may uncover hidden saving potentials within the fluid distribution system and allow more exact performance indicators, improving energy efficiency.

Request for a quote

TETHYS OIL SUPPLIES & SERVICES

Malta

Tethys Oil Supplies & Services is a distributor of FMC Smith Meter® flow meters, strainers, PD Meters, and Accu-Load. Known worldwide for its ability to produce reliable, accurate and consistent measurement results, the Smith Meter® brand is one of the most accurate and cost-effective options available to the industry. In addition, the Smith Meter Guardsman™ is lightweight and compact for easy integration into packaged systems. Also available through Arm-Tex is the Smith Meter® Ultra Series. Backed by FMC Technologies, the Ultra Series is the cutting edge solutions for custody and non-custody transfer measurement applications. This non-intrusive design has no moving parts to provide a low maintenance measurement solution and offers a wide dynamic flow range, wide viscosity application range with low differential pressure. Applications include: blending, batching, dispensing, inventory control, and custody transfer of oils, solvents, chemicals, paints, fats, and fertilizers.

Request for a quote

VENRIUS B.V.

Netherlands

Venrius has a broad range of purgemeters. The purge rotameters are intended for general use as a low-cost method of flow indication. It is suitable for the majority of non-critical purge applications that do not necessarily require high flow measurement accuracy. Their primary use is to regulate small gas or liquid purge streams. They are used to keep instruments from coming into contact with hot and corrosive fluids, to keep pressure taps from plugging, to keep optical devices clean, and to keep electrical devices from igniting when they come into contact with flammable materials.

Request for a quote

VENRIUS B.V.

Netherlands

Venrius' portfolio includes a variety of variable area flowmeters. Metal tube variable area flowmeters, glass tube variable area flowmeters, and purge rotameters are the three main types. The volumetric flow rate of liquids and gases is measured using the float principle in metal and glass tube flowmeters. The purge flowmeter is intended for general use as a low-cost method of flow indication. It is suitable for the majority of non-critical purge applications that do not necessarily require high flow measurement accuracy.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IPF ELECTRONIC GMBH

Germany

The function of the flow sensor is based on the calorimetric principle. The probe is heated up from the inside a few degrees Celsius in relation to the flow medium, in which it protrudes. When the medium flows, the heat generated in the probe is dissipated through the medium. The temperature within the sensor is measured and compared with the likewise measured medium temperature. From the obtained temperature difference the flow state of each medium can be derived. These sensors are applied in areas such as monitoring of cooling systems, ventilation systems, pump dry running by checking the presence of liquid or gas flows.

Request for a quoteResults for

Flow sensors for liquids - Import exportNumber of results

19 ProductsCompany type