- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flour mills

Results for

Flour mills - Import export

ROBINSON CO.

Turkey

Molasses Mixer designed for homogeneous mixing of liquid sweetener to product additives in feed mill plants. U type body in Carbon Steel ST37 metarial up to requirement. Liquid with 1-11 % is mixed homogeneously. Maximum mixing is provided by heating molasses 40 - 42 degress. Applications Fields Food Business Industries Flour Mills Semolina Mills Seed Cleaning Facilities Malt Factories Feed Mills Corn Mills Grain Storage Silos

Request for a quote

ROBINSON CO.

Turkey

It performs the dissolving and grinding process in the appropriate semolina passages of flour diagrams, in this passage it increases the flour yield at high rates. This process is carried out with lower energy than other grinders. These machines are used in coarse and fine semolina passages, It can be mounted right after the rolls or on the upper turning points of the pneumatic carrier pipes to be used as elbows. Application Fields ◾ Flour Mills ◾ Semolina Mills

Request for a quote

ROBINSON CO.

Turkey

It is used for cleaning and classifying semolina in flour and semolina factories. The product, whose flow rate can be adjusted, is evenly distributed over the entire screen surface by means of a curtain. Screening process is carried out with 2 or 3 layers of telero. With the aerodynamic air channel and adjustment valves, an equal vacuum is created on the whole screen surface, the products with extended adhesion surface such as bran and bran are separated from the product by vacuuming and pushed into the outlet channel. The product (semolina) free from bran is classified according to its grain size by means of sieves. Application Field ◾ At food industry ◾ Flour mills ◾ Semolina mills

Request for a quote

ROBINSON CO.

Turkey

It is used for breaking and crushing wheat in flour factories. The most important machine of the flour mill, the roller mill consists of two pairs of roller balls operating in parallel. Unlike the pneumatic roller, the incoming product amount is measured with the help of a sensor or load cell. Feeding rollers change speed according to the incoming product amount and provide homogeneous flow. At the same time, the gap between the rolls is closed by pneumatic pistons and allows the product to be grinded by passing through the rolls. The bearings of the rolls are ductile iron and the arms of the rolls are conical. It is produced with gear drive and belt drive. It can also be produced with an optional touch control screen. Especially thanks to the side covers that can be opened one by one based on the opening system, it provides fast and easy access and the possibility of rapid ball removal with the cover opened on the ball.

Request for a quote

ROBINSON CO.

Turkey

The control sieve is used for the final control before packaging in the packaging unit of the flour factories. The product arriving at each passage of the square screen enters through the pressure pipe and moves vertically and horizontally through the pre-set flow paths along the passage. The final checks are made after the flour sifting process. The flour, whose last checks are made, is directed to the bagging process. Apart from flour and semolina factories, it is used in processing plants of wheat, corn and similar grains, in feed mills, in various food products processing plants for the final screening of mixed feeds and for the sifting of large-grain corn, crushed pellet feed, barley, oats and similar processes. Application Fields ◾ At flour mills: For wheat, corn and similar grain processing plants ◾ At feed mills: For final sifting of formulated feed meals, corn, crushed pellet feed, barley, oats and for removing the remained coarse materials after grinding and similar processe

Request for a quote

ROBINSON CO.

Turkey

This machine is used in flour mills to separate the stuck core particles in the product coming from the roll. In this way, in flour production; Soft separation does not spoil the product. Both floor and ceiling hanging position shape, Right and left directions of spinner bars, Low power requirement, Coupling or pulley connection system Application Fields ◾ At flour mills ◾ At coarse and fine semolina passages ◾ After roller mills or before plansifter inlet

Request for a quote

ROBINSON CO.

Turkey

This machine provides the sorting of crushed corn with speed adjustment. It makes density and size classification with vibramotor from sheets of different sizes. It separates the sticky products (bran, flour, corn...) that can be obtained from corn with the help of vacuum.

Request for a quote

ROBINSON CO.

Turkey

It transports the bagged product from one place to another, the combined belt conveyor supports the belt conveying process. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

It is a conveyor belt system with general ease of use that can be used in any area where loading and unloading operations are performed, provides convenience in terms of occupational and worker health, minimizes damage to products. It provides convenience in stacking and storage. It can be used as highly adjustable, stationary and mobile (mobile). Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories ◾ All Transport Operations

Request for a quote

ROBINSON CO.

Turkey

The Conveyor used in grain, creals and food processing plants in the transport unit. Tube Conveyor is used for the horizontal transporttation of products in flour plants. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

Depending on the central control, it takes action by being set up with chain gear and ensures the transportation of the falling product. The body is made of steel. It has idler drive bearing system. It has been designed with a special tensioning device. It varies according to the desired capacities. Carrier plates are made of hardened steel. It is used wherever horizontal transportation is possible. It is used in feed, food, chemical, mining, sawdust and soil industries. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

It is utilised to partitioned air from the item, which is released from a typhoon separator into pneumatic frameworks. It is introduced underneath the twister separators and air filters. It works with the negative weight and in addition an air seal against spillage. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories ◾ Biscuit and macaroni plants

Request for a quote

ROBINSON CO.

Turkey

It is used for breaking and crushing wheat in flour factories. The most important machine of the flour mill, the roller mill consists of two pairs of roller balls operating in parallel. Unlike the pneumatic roller, the incoming product amount is measured with the help of a sensor or load cell. Feeding rollers change speed according to the incoming product amount and provide homogeneous flow. At the same time, the gap between the rolls is closed by pneumatic pistons and allows the product to be grinded by passing through the rolls.

Request for a quote

ROBINSON CO.

Turkey

◾ Fully PLC controlled. ◾ Precision weighing and long life with stainless steel load cells. ◾ 5/10kg.-10/25kg.and 25/50kg. weighing December. ◾ Automatic filling into bags with an open mouth. ◾ Lower and upper tolerance values that can be programmed separately. ◾ Automatic sack shaking mechanics. ◾ Separate weighing container feeding system according to the type of product to be bagged. ◾ Double coil feeding driven by separate motor. ◾ Single coil feeding driven by two-speed motor. ◾ Belt feed driven by two-speed motor. ◾ According to the product to be bagged and the desired tolerance, 13-22 tons/hour (50 kg. capacity Decoupled in bags) between. ◾ Special system panel from IP54 protection class ◾ Regulation bunker weighing unit and special vibration units in unloading bunkers. ◾ Easy calibration with keypad. ◾ Height adjustable sewing machine column.

Request for a quote

ROBINSON CO.

Turkey

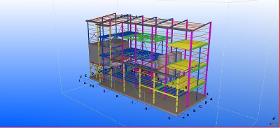

There are several reasons why steel structures are preferred over reinforced concrete structures. The main reasons are fast generation and seismic resistance. Steel structure reduces loss of life and property during disasters and ensures safety. Metallurgical facilities, industrial buildings, sports facilities, hangars, warehouses - these are structures in which metal structures are often used. Light or heavy steel is preferred depending on the project requirements. Since heavy steel is generally preferred in industrial buildings, its load-bearing capacity is suitable for industrial applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROBINSON CO.

Turkey

It is utilized as a part of the flour plants to isolate any outside material that might be blended into conclusive item amid processing procedure or capacity. The remote materials isolated from item before pressing, item stockpiling or mass stacking storehouse. FEATURES - MFDJ It is utilized as a part of the flour plants to isolate any outside material that might be blended into conclusive item amid processing procedure or capacity. The remote materials isolated from item before pressing, item stockpiling or mass stacking storehouse. - MFNM - Best machine in practice. - Most economic spare parts. - Long life. - Seperation of fat with intensive operation. - Nindamac helps to achive high aqualit diffrent granulation of finished product with low fat content. For high technology degermination done by Nindamac by the

Request for a quote

BERG TRADING COMPANY

Netherlands

SPECIFICATIONS OF WHITE MAIZE: 1. Commodity: white maize 2. Moisture: 13% max 3. Protein: 9% 4. Purity: 98% 5. Broken: 2% 6. Aflatoxin: 10 ppb(human consumption) 7. Packing: 50 kg pp bag Packing - 25 kg or 50 kg pp bag Printing Bag - As per the buyer needs

Request for a quote

RPWORLD

China

CNC Machining at RPWORLD meet the diverse needs of clients ranging from single part to low- to mid-volume production. Our CNC machines run 24/7, ensuring that your high precision, complex geometries parts delivered in as fast as 3 days. We have equipped with 3-axis, 4-axis, and 5-axis machines, drilling machines, lathe machines and EDM, which are designed for creating complex shapes with high precision. The cutting-edge machines offer tight tolerances DIN ISO 2768 medium (fine), and wide machining range from 1mm to 1600mm. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

AG FEEDING

Poland

Very rich in unsaturated fatty acids: Monounsaturated - 15,7% of total fat Polyunsaturated - 73,5% of total fat Omega 3 fatty acids - 56,7% of total fat Omega 6 fatty acids - 16,8% of total fat Omega 9 fatty acids - 14,8% of total fat

Request for a quote

MDM INTERNATIONAL BRANDS SP.Z.O.O

Poland

available wheat flour 1kg if you need others types you can ask

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used in the flour mills to prevent infestation of insects to be grown in the processed product

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used in the flour mills to prevent infestation of insects to be grown in the processed product

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to fill in the gap between the big plan sifter and the laboratory plan sifter. The unit is strongly advised to be used after product silo before packing of products

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to feed regularly the granular or powdery product into a conveying line or a machine at a suitable rate especially at flour mills

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to feed regularly the granular or powdery product into a conveying line or a machine at a suitable rate especially at flour mills

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to break endosperm flakes, which are obtained after reduction rolls, so that it helps for the process of the flour production

Request for a quoteResults for

Flour mills - Import exportNumber of results

152 ProductsCountries

Company type

Category

- Flour milling - machinery and equipment (125)

- Flour-milling (92)

- Flour and semolina (8)

- Food Industry - Machines & Equipment (7)

- Bread, factory-baked (4)

- Troughs and feeders (3)

- Common wheat (2)

- Oils, cooking - machinery and equipment (2)

- Conveyor systems (1)

- Crushing and grinding machinery (1)

- Flow meters (1)

- Food Processing (1)

- Food industry packaging machinery (1)

- Food packaging (1)

- Milling - steels and metals (1)

- Organic food (1)

- Packing and packaging - machinery and equipment (1)

- Silos, farm (1)

- Steel, structural (1)