- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flexible heaters

Results for

Flexible heaters - Import export

FRIEDR. FREEK GMBH

Germany

We can offer flexible heating elements manufactured from three different insulation materials: silicone, polyimide (Kapton) or polyester. Each of these materials possess different properties which make them suitable for diverse applications. Silicone heaters can also be produced in very large sizes, whereas polyimide is significantly thinner and polyester unbeatable in price when it comes to high quantities. All three of them are bespoke products made according to your needs, so within the bounds of what is technically feasible you as the customer can determine almost every feature of your heater. This can include; voltage, wattage, dimensions, shape, sensors, leads, plus much more. Due to their low thermal mass flexible polymer insulated heaters distinguish themselves by a very short response time and excellent controllability.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Flexible silicone heaters are resistant to permanent temperatures up to 200°C, with self-adhesive foil 180°C should not be exceeded. Higher temperatures of 230°C are possible for a short time without destroying the heater. The temperature that will be reached within the application, generally is not easy to predict, as there are many influencing factors. In addition to the power, resp. surface load, this also includes mass and type of the material to be heated (thermal conductivity, surface quality, etc.) installation / assembly situation (bonded, vulcanised, clamped, etc.), ambient temperature, air movement and, of course, the control technology used. Application examples for silicone heater mats include: canteen kitchen technology / catering, anti-fog and anti-freeze applications, tool or plate heating in machines, 3D printers, laboratory equipment, composite materials repair, joint curing and much more.

Request for a quote

EMBRO GMBH

Germany

We are using CNC - technology for the laying of thin and insulated heating wires on a variety of carrier materials in order to manufacture all kinds of heating elements. We can work up to sizes of 2 x 2 m, and we can realize medium series (500 - 10.000pcs.) as well as high volume productions (up to 1 million pcs.). All voltages from 3,7V up to 480V are possible. With our elements we can reach temperatures of up to 200°C. Please do not hesitate to contact us!

Request for a quote

FRIEDR. FREEK GMBH

Germany

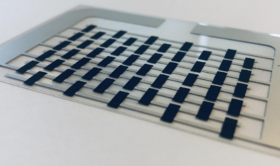

Polyester heaters also referred to as Polyester film heaters or Polyester foil heaters consist of an electrically conductive ink between two insulating respectively carrier layers of polyester. With a maximum size of 600 x 1000 mm, their average height is only 0.2 mm. As the picture examples show, practically any shape and type of cut-out is possible. Polyester foil heaters are resistant to permanent temperatures of up to 90°C (max. 100°C for short periods). It is generally not possible to predict which temperature a Polyester heating element will reach in the application, as there are extremely many influencing factors. These include not only the power, but also the mass and type of goods to be heated, the ambient temperature, air currents, the type of mounting and, of course, the control technology. Typical applications for Polyester heaters are e.g. cup warmers in coffee machines, mirror heaters, plate heat exchangers, flat applications with a target temperature below 90°C.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Silicone heaters and Kapton heaters are preferred surface heating elements for laboratory equipment and medical technology due to their easy handling and variety of shapes. Like Kapton polyimide heating foils, silicone heaters are resistant to continuous temperatures of up to 200 °C, with self-adhesive foil up to 180 °C. When designing silicone heaters and Kapton foil heaters, the designer has almost unlimited degrees of freedom. This applies to the minimum and maximum dimensions, which are set within wide limits, as well as to contours and recesses, holes and feed-throughs of any kind. The good shape flexibility of silicone heating mats and foils as well as Kapton polyimide heaters also enables the heating of cylindrical, conical or rounded surfaces. The resistance of polyimides to fungi, bacteria, ozone, weather, ageing and most chemicals, acids and solvents is very good, making polyimide (Kapton) heaters an ideal solution for many critical applications.

Request for a quote

SILGA SPA

Italy

FPCs solutions for batteries include Flexible Heaters , an innovative technology developed for the thermal management system of the batteries; in this way, the performance of the battery is improved, prolonging its life, especially when it is located in areas with extreme climatic conditions. Flexible heaters can be made using the traditional technique or the new Printed Electronics technology , with the possibility of also using PTC inks for automatic temperature regulation. Furthermore, the “Made in Silga” Flexible Heaters offer the possibility of integrating special finishes to guarantee excellent performance in any working condition.

Request for a quote

SILGA SPA

Italy

Lightweighting, freedom of design and cost reduction are the drivers for every application and sector. For this reason, Silga is increasingly called upon by its Customers to become a partner in the development of solutions that achieve this objective. Especially if they are non-standard solutions. One of the most important and successful is that of FLEXIBLE HEATERS . In this area, in fact, skills related to: Flexible PCB's Alternative materials Chemical etching capability of metals other than copper Know How in using functional inks Exclusive surface finishes developed by Silga. Production lines adequate for the required volumes

Request for a quote

FRIEDR. FREEK GMBH

Germany

In general, a Kapton film heater is always more expensive than a silicone heater or polyester heater. Where chemical resistance or the weight of the flexible heating element plays an important role, however, Kapton heaters are the ideal solution. The resistance of Kapton Polyimide to fungi, bacteria, ozone, weather, ageing and most chemicals, acids and solvents is very good, so that heating elements made of Polyimide (Kapton) are an ideal solution for many critical applications. Kapton foil heaters are also silicone-free and are characterised by an even heat distribution. The dielectric strength of a Polyimide film is very high and so the flexible Kapton (Polyimide) heater can be very thin. Due to the small thickness, the heat transfer to the component is improved and higher surface loads are possible. Typical applications for Kapton film heaters are: Laboratory technology, aircraft electronics, printers, diagnostic instruments, vacuum chambers, medical equipment and many more.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Square stainless steel tubular heaters BASE-flex (1.4541) are a reliable industry standard for the use in heating platens and manifolds. In contrast to traditional tubular heaters with a round section which have to be bent by machines, square BASE-flex can be fitted into any rectangular groove with simple hand tools. Moreover, the square shape results in a bigger heat emitting area of up to 80% compared with a corresponding round section. Finally, the easy manual mounting saves the usually high technical expenditure for casting-in / soldering / cementing of bent round tubular heaters. A soft version of the BASE-flex, the NICKEL-flex (2.4068) is available as special execution. Due to the soft, easy to form nickel material, the NICKEL-flex is suitable for manual mounting with hand tools in round sections, too. Furthermore, Nickel has a better capability to conduct heat compared with stainless steel.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Advantages of Heating Plates with Square Cartridge Heaters: -> Simple plate manufacture due to rectangular groove geometry, no deep-hole boring -> Simple heater installation by bending and pressing along the plate surface -> Complex plate geometries with bores and openings -> Optimal heat transfer due to 75% surface contact -> No casting with heat conductive compound -> Uniform temperature profiles due to thermally optimized groove layouts/power distribution and utilization of insulation plates -> high process temperatures (up to 450°C in aluminium, up to 700°C in stainless steel) Example "Heated Stamp": D=100 mm out of tempered tool steel up to max. 700°C continuous temperature. Fitted with 2 Square Cartridge Heaters 1500 W/ 230 V, 4,5 x 4,5 mm x 600 mm, with 50 mm unheated at the termination end. Annealed and formable with a nickel sheath, resistant up to 850°C surface temperature. Connection by fibreglass insulated pure nickel high-temperature leads (max. 500°C)

Request for a quote

FRIEDR. FREEK GMBH

Germany

Flexible Polyester Heaters consist of a conductive ink between two insulation layers of polyester. The heater can be pressed on or fixed with a self-adhesive foil. Wrapped in PVC the use in liquids is possible as well. Typical standard applications are e.g. mirror heaters, water bed heaters, or low temperature room heaters. For terrarium and aquarium heaters we offer standard elements as well.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Micanite is a kind of insulation paper which is impregnated with a heat resistant binder and afterwards pressed in several shifts under heat and high pressure to plates. This material is heat resistant up to 350 °C, as special construction (Phlogopit) up to 450 °C, and is used for the wire wound formers as well as for the encapsulating cover plates of mica surface heaters. Because of the typical "sandwich"-construction of Micanite Flat Heating Elements and their high watt density it is necessary to use a platen to press the mica heater onto the surface to be heated. Established on the market for round Flat Heating Elements are some standard dimensions (Ø 58 / Ø 65 / Ø 80 / Ø 100 / Ø 160 / Ø 260 mm). But normally Micanite Surface Heating Elements are constructed on customer's request. Mica heaters can be metal sheathed for higher mechanical stability. This makes the heater flexible, so that it is also possible to build a band heater.

Request for a quote

PEEKCHINA CO., LTD.

China

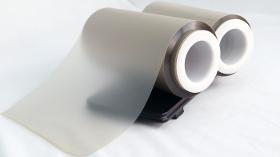

Material: Amorphous, Semi-crystalline and Mineral Filled Semi-crystalline. PEEK (polyetheretherketone) Film Provides: ● High Temperature Performance ● Excellent Tribological Properties ● Broad Chemical Resistance ● High-Strength & Toughness ● Electrical Stability & Radiation Resistance ● Low Smoke & Toxic Gas Emission ● High-Purity, extremely low extractables Appication: ● Micro speaker diaphragm, dome tweeter. ● Presslire exchanger and senior oliaphragin. ● Aerospace high-speed rail insulation and TAB heat insulation components. ● Thrust washers for micro motors, gaskets for automobiles. ● High-temperature resistant label, pressure sensitive tape substrate. ● Insulation layer of electric vehicle battery. ● Flexible film surface heater. ● Wire, cable, insulation and wrcop sheaths.

Request for a quote

SILGA SPA

Italy

To effectively respond to the technological expectations of its customers and satisfy the different market needs, Silga is able to offer a wide and complete range of products ranging from printed circuits with standard characteristics to highly complex ones. Silga offers single-copper flexible PCBs , double-sided flexible PCBs with metalized holes (PTH), flex therm for heat dissipation, Gigaflex for the sensorized connection of the battery pack to the BMS in e-vehicles and Flexible Heaters for heating and removal of the condensation. Silga flexible PCBs find application in numerous sectors such as automotive, EMS, industrial, medical and wearable.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Cu-Ni 715 is a copper-nickel alloy that is resistant to corrosion in sea water. The alloy has good fatigue strength and relatively high thermal conductivity. This alloy is used mainly for flexible metal foil heaters. The alloy is readily formed in the annealed temper, and can be joined by the standard welding, brazing and soldering processes. Available Sizes: Cu-Ni 715 is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.010” (0.0127 mm to 0.254 mm) in widths up to 12” (304.8 mm). The material conforms to ASTM B122 and UNS C71500.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® 80/20 A is a resistance alloy used in electric heating applications. It is recommended for use in dry air applications up to 2150°F with good hot strength. Such as, flexible metal foil heaters and airbag igniters. The alloy forms rather well and has good welding characteristic. Caution should be used to avoid extended exposure to elevated temperature in marginally oxidizing or partially reducing atmospheres as it would be susceptible to “green rot” corrosion, carburization and sulfurization. Available Sizes: HPM® 80/20 A is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.050” (0.0127 mm to 1.27 mm) and width up to 12” (304.8 mm). The material conforms to ASTM B-344. Foil product may be supplied in thickness to 0.0001” (0.00254 mm) in width up to 4.0” (101.6 mm).

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® 600 is well suited for severe corrosive environments and is oxidation resistant through 2150°F. Such as, metal diaphragms for aerospace sensors, flexible metal foil heaters and metal diaphragms for burst discs. The strength can be increased by cold working. The material has good elevated strength retention through 800°F. The alloy is readily formed in the annealed temper, and can be joined by the standard welding, brazing and soldering processes. Available Sizes: HPM® 600 is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.050” (0.0127 mm to 1.27 mm) and width up to 12” (304.8 mm). It is also available in foil as thin as 0.000100” (0.00254 mm) in widths of 4.0” (101.6 mm) maximum. The material conforms to ASTM B168, AMS 5540, MIL N 23228 and UNS N06600.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® 201 Nickel is a commercially pure wrought Nickel. With low carbon, the material has excellent corrosion resistance with high thermal and electrical conductivities. Making it perfect for use in flexible metal foil heaters. The alloy can be formed by all conventional cold-forming methods and can be joined by welding, brazing and soldering. The corrosion resistance is generally very good in most mediums, although it is subject to intergranular embrittlement by sulfur compounds above 315°C. Available Sizes: HPM® 201 Nickel is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.020” (0.0127 mm to 0.508 mm) in widths up to 12.0” (304.8 mm). It is available as foil as thin as 0.000100” (0.00254 mm) to 4.0” (101.6 mm) maximum width. The material conforms to ASTM B162, and UNS N02201.

Request for a quoteResults for

Flexible heaters - Import exportNumber of results

19 ProductsCountries

Company type