- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- finishing tools

Results for

Finishing tools - Import export

SEMIN

France

TECHNICAL DETAILS Paste coating for a good finish on interior walls and ceilings. Provides excellent surface preparation before painting or hanging coverings. COMPOSITION AND APPEARANCE Emulsion resin, calcium carbonate, rheological agent and various additives. SEMIN ENDUIT DE LISSAGE is a water-based coating. The paste is white in colour. COVERINGS • Wallpaper • Paint • Wall covering SUITABLE SURFACES Interior walls and ceilings • Plasterboards • Plaster tiles • Concrete • Cement coating TECHNICAL CHARACTERISTICS • Density of paste : 1.9 • Granulometry : fine • pH : 7 Adhesion : complies with NFT 30 608 PACK SIZE 4 and 10 kg buckets on shrink-wrapped pallet. APPLICATION Apply manually using a smoothing trowel or a filling knife. The maximum thickness will be 2 mm per coat. Allow to harden and remove imperfections before sanding, if necessary. Print the SEMIN ENDUIT DE LISSAGE if applying satin-finish or gloss paint. Clean tools in water.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Burrs are splinters, fraying, or edges that occur during machining processes. Tyrolit tools make removing these easy. Our nonwoven products are ideal for finer deburring work on materials like stainless steel, nonferrous metals, titanium, and high-alloy steels. Applications include surgical instruments, turbine construction, products for the chemical and food industries, design objects, and more. For coarser deburring and rough grinding, flap or fiber discs are typically used. Tyrolit's product range for deburring and finishing surfaces is extensive. It includes various non-woven products like discs, rolls, belts, and points for use on steel, stainless steel, nonferrous metals, and plastic. Our high-quality polishing program, featuring first-class discs for angle grinders and different polishing pastes, is perfect for removing final scratches. Tyrolit offers tools for every finishing application.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Honing tools from Tyrolit deliver the smoothest surface effects with precision down to the smallest µ-range, essential for industries like cutlery, ski, automotive, watchmaking, and medical technology. These sectors benefit from our extensive range of honing and finishing tools, known for high precision. Tyrolit's dynamic innovation in quality and processes ensures our partners are well-equipped for industry challenges. Best Honing Tools for Various Industries: Our broad assortment offers optimal solutions for any application. In the automotive industry, our products use special polyester film. For superfinishing, the Facetec MF line offers high process stability and cost-effectiveness. The thermal glass industry benefits from our elastic bonded tools for easy metal layer removal. The ski industry uses resinoid-bonded elastic tools to sharpen edges. For precision machining of hip and knee joints, the medical industry relies on our diamond and CBN tools.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In high-pressure grinding, the quality of the grinding wheel is crucial for the process result. It determines whether economical snagging of steel can meet technological requirements. Tyrolit's high-performance grinding wheels are designed to quickly and precisely achieve the required quality for further processing, supporting the production process. Snagging is the most common process for plastering semi-finished products. Our tools ensure high process quality, targeted and controllable stock removal, high production output, and consistent surface quality. They also guarantee high economic efficiency, easy handling, and low fault susceptibility. The SECUR line abrasives demonstrate the capabilities of our product range in high-pressure grinding. Many steel grades have surface defects, scales, and decarburization zones after continuous casting, which must be efficiently fettled before rolling mill processing.

Request for a quote

THOMSON MACHINERY BV

Netherlands

1. The Thomson adopts advanced DSP system with USB connection, operated with handle, convenient operation.2. The whole machine is welded with seamless steel structure, which is high temperature annealing and vibrating stress relief, so the machine body is stabilized and will not be deformed forever.3. The ATC CNC adopts domestic top brand stepper motor to ensure high precision.4. Operating system has friendly easy operation interface, english suggestion and simple setting method.5. Spindle System is divided into single axial and biaxial.6. Transmission system adopts Hiwin square rail and ball screw to control the linear error effectively .7. One-time tool setting to finish the whole workpiece.8. Compatible with several CAD/CAM design software such as Type3, Artcam, etc.9. The ATC wood lathe can completely work offline and do not take any computer resources.10. 4th axis for 3D carving and cutting.11. Automatic tool changer system.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Process:Precision Maching Product Name:Precision Machining Stainless Steel Union Joint Main Use:Industry,Machinery Parts,Chemical Industry Technical parameter Technical:Precision Machining Material: Stainless Steel Machining Surface Roughness:Ra0.8-1.6 Support File Format : ProE (.igs , .stp) , Auto CAD , PDF, Jpeg, Jpg, Png Machining Equipment : Inclined Bed ,CNC Turning Machine Surface Finished : Nickel Plating Measuring Tool : Three Coordinate, Micrometer, Caliper, Height Gauge,Screw Gauge,Outside Diameter Gauge Inspection : First Checking , Checking , Final Checking QC Report:Material Stainless Steel Report,Product Ddimension Inspection Report Technical Process Order Stainless Steel Tub Cut Blank Precision Machining

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Technical : Aluminium Hot Forging + Precision Machining Product Name : Aluminum Fastener Main Use : Auto Parts Technical parameter Technical Aluminum Hot Forging Fastener + Precision Machining Material: Al-6061 T6 Al-6063 Material Standard GB,ASTM,AISI,DIN,BS,JIS,NF Forging Weight 0.3kg~5kg Forging Dimension Tolerancez: CT8-10Grade Forging Surface Rough: Ra6.4 – 3.2 Rough of Machining Surface:Ra0.8-1.6 Support File of Format: ProE (.igs , .stp) , Auto CAD , PDF, Jpeg, Jpg, Png Heat Treatment: Quenching and Tempering , High Frequency Quenching Machining Equipment CNC Center,CNCs, Drilling Machine. Surface Finished Hard Anodizing Measure Tool: Micrometer, Caliper, Height Gauge,Screw Gauge Inspection First Checking , Checking , Final Checking QC Report:Material Report, Product Ddimension Inspection Report.

Request for a quote

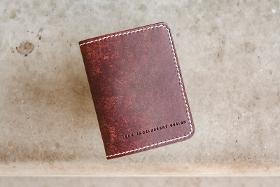

LEON ENGELBRECHT DESIGN CC

Namibia

Please contact us to find out what colours we currently have in stock! Our Updated Compact wallet from our AXEL range. Made from some of the best, premium Vegetable Tanned leather in the world with amazing textures and colours, using our best hand tools and individually finished by hand. Hand sewn using the saddle stitch with natural burnished edges. Features a unique zig-zag stitch with white contrasting TIGER (waxed and strong polyester) thread. Features nice big cards slots to easily store 2 cards per slot. Has one deep cash slot for your folded cash. Also features a 'quick access' slot on the outside for your most used card. The wallet closes with a small closing snap button. This leather will develop a rich and dark patina with use.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Their flexibility and high performance make BEHRINGER tabletop machines the ideal solution for the medium ton range. The table moves the weight BEHRINGER tabletop machines are ideal for use in forges, rolling mills and die casting factories, in steel finishing works and for tool and mold making. Their individually traversable material clamping vices and blade guide arms make these ideal for cutting bulky materials. The low table height makes this type of machine ideally suited for use on normal hall floor level. BEHRINGER tabletop machines are supplied as standard in semi-automatic form. Automation is possible by upgrading with an additional material clamping vice at the end of the table. Positioning takes place on an axiscontrolled basis. Optionally available is 90° rotatable blade guide for vertical and horizontal sawing to allow notching of materials.

Request for a quote

STRONG MAGNETS GMBH

Germany

Neodymium magnet (aka NdFeB magnet), is the third generation of rare earth magnet, which is composed of Neodymium, Iron, Boron and a few transition metals. With high remanence, high coercive force, high energy product, and high performance /cost, Neodymium magnet is currently the strongest magnet available in the world. Manufacturing Process Neodymium, Iron, Boron and a few transition metals will be mixed into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing the powder in a solid state. There are two ways of pressing die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances. Machining & Tolerance Generally, Neodymium magnet must be machined using diamondgrinding techniques. Sometimes, machining operations may be performed on Neodymium materials with carbide tools, but surface finishes thus obtained may be less than optimal.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming and scoring hidden airbag compartments on thermoformed skin. After the fabrication of IP skins through thermoforming, two separate fabrication steps are still needed before foaming. In the first step, the thermoformed skin will be trimmed in the external zone through punching or a blade cutting process. Depending on the requirements, this is where FRIMO's blade cutting equipment comes into operation. In the second step, the skin will be weakened in the airbag area by a blade. By using the new FRIMO FlexTrim Combi Trim Scoring machine, both steps can be realised at once. The skin is positioned in a common component fixture and finished with two different cutting tools. The new system concept, with its flexible design and layout possibilities, offers a variety of options for combinable process and operation groupings. As an example : one 2-station system with two robots, which are equipped with automatically exchangeable cutter heads, and where two different products

Request for a quote

RHODIUS ABRASIVES GMBH

Germany

Unitised disc for use with the quick change system. For burr removing, blending and finishing. • Decorative surface finish • Long lifetime • Quick tool change without bonding or sliding

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

With the DHC Premium solid carbide end mills, LMT Tools significantly increased the performance of the low-vibration premium tools: 25 % added machining volume is the result of different helix angles in connection with newly developed, stable front cutting edges and peripheral teeth. Additionally, the new cutting material LCPK30M including an innovative PVD high-performance coating contributes to an improved tool life and a safe chip removal. A special performance feature of the DHC Premium end mill (Different Helix Cutter) by LMT Fette consists in its multifunctionality: it allows the user to rough and finish with the same tool. It can also produce narrow projections and up to 2xd-deep slots in steel and cast materials with exceptional surface quality. Advantages: - Increase of the machining volume by 25 % - Increased process reliability due to stable cutting edges - Multifunctional – roughing and finishing with the same tool

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

LMT Tools has developed the CopyMax family, specially for the die and mold making industry The latest addition to the family is the one-sided indexable insert CopyMax1. It is an alternative for the reliable CopyMax2 with a two-sided indexable insert. opyMax1 and CopyMax2 prove their advantages above the competition during the roughing and the semi-finishing processes. Both tools are manufactured using the manufacturing process HQS (High Quality Sintering), which is registered for patent approval. For the first time, HQS allows for pressing and sintering a ball nose copy insert complete, resulting in precision sintered cutting edges. In addition to introducing the new indexable insert CopyMax1, LMT Tools has developed new shanks for the CopyMax. A cylindrical steel shank version is available in two different lengths, and the cylindrical bolt-on milling cutter are both new to the program. Both milling systems are designed with internal coolant supply.

Request for a quote

DORTEX MBH

Germany

Cottonera woven labels and name tapes have many uses. From the traditional laundry label to labels for your own handmade creations: They are always in two colors and you can order them in your desired length, choose between the sew-on or the iron-on version and much more. With our extremely precise configuration tool, your finished woven labels will be delivered to your door just as you imagined them. Cottonera Classic labels are the perfect beginner label for anyone who wishes to label handmade items in an attractive and low cost way. Weaving on the shuttle loom gives the Classic labels their particularly attractive structure. Select from widths of 10mm, 15mm and 25mm, various background and font colors and whether you want the sew-on or iron-on version. You can use our fonts and motifs or upload your own logo.

Request for a quote

DORTEX MBH

Germany

Cottonera woven labels and name tapes have many uses. From the traditional laundry label to labels for your own handmade creations: They are always in two colors and you can order them in your desired length, choose between the sew-on or the iron-on version and much more. With our extremely precise configuration tool, your finished woven labels will be delivered to your door just as you imagined them. Cottonera Classic labels are the perfect beginner label for anyone who wishes to label handmade items in an attractive and low cost way. Weaving on the shuttle loom gives the Classic labels their particularly attractive structure. Select from widths of 10mm, 15mm and 25mm, various background and font colors and whether you want the sew-on or iron-on version. You can use our fonts and motifs or upload your own logo.

Request for a quote

DONLOUCO IRELAND LTD

Ireland

Donlouco has extensive experience in forging of hydraulic components, Cylinder bases, Flanged components and Rod eye. Part weights from 0.5Kg to 50Kg. Max forging capacity: 1,600 Ton. Forged parts for the hydraulics industry with secondary CNC Milling & Turning Forging capability from small detailed parts to large forgings of 50Kg. Maximum forging capacity of 1600 Ton. Forged parts mostly CNC machine to finished part level. Forging tools designed and managed and can be reversed engineered from finished part drawings by Donlouco. All steel grades to meet customer requirements and European standards. Forged parts can be fully tested, tensile, impact etc at approval stage and by sampling as required. All parts fully checked and inspected before shipping with full traceability and reports available with all shipments.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HPTEC GMBH

Germany

Allround router with quiet operation for machining of composite materials such as CFRP and GFRP in the diameter range Ø 0.20 to 6.00 mm. Advantages: Good surface, no delamination and fiber projections, low vibration, ideal for trimming, especially for dry machining suitable (low heat) For advanced materials such as carbon, carbon fiber, glass fiber (fiberglass) with multidirectional and unidirectional fiber orientation Roughing and finishing tools with and without diamond coating. Pulling, pushing (cutting pressure up / down, right twistes / left twisted, right hand cutting / left hand cutting)

Request for a quote

HPTEC GMBH

Germany

Allround router with quiet operation for machining of composite materials such as CFRP and GFRP in the diameter range Ø 0.20 to 6.00 mm. Advantages: Good surface, no delamination and fiber projections, low vibration, ideal for trimming, especially for dry machining suitable (low heat) For advanced materials such as carbon, carbon fiber, glass fiber (fiberglass) with multidirectional and unidirectional fiber orientation Roughing and finishing tools with and without diamond coating. Pulling, pushing (cutting pressure up / down, right twistes / left twisted, right hand cutting / left hand cutting)

Request for a quote

HPTEC GMBH

Germany

Allround router with quiet operation for machining of composite materials such as CFRP and GFRP in the diameter range Ø 0.20 to 6.00 mm. Advantages: Good surface, no delamination and fiber projections, low vibration, ideal for trimming, especially for dry machining suitable (low heat) For advanced materials such as carbon, carbon fiber, glass fiber (fiberglass) with multidirectional and unidirectional fiber orientation Roughing and finishing tools with and without diamond coating. Pulling, pushing (cutting pressure up / down, right twistes / left twisted, right hand cutting / left hand cutting)

Request for a quote

HPTEC GMBH

Germany

Allround router with quiet operation for machining of composite materials such as CFRP and GFRP in the diameter range Ø 0.20 to 6.00 mm. Advantages: Good surface, no delamination and fiber projections, low vibration, ideal for trimming, especially for dry machining suitable (low heat) For advanced materials such as carbon, carbon fiber, glass fiber (fiberglass) with multidirectional and unidirectional fiber orientation Roughing and finishing tools with and without diamond coating. Pulling, pushing (cutting pressure up / down, right twistes / left twisted, right hand cutting / left hand cutting)

Request for a quote

BIBIELLE S.P.A.

Italy

BIBIELLE offers a very good satin finish machine, particularly suitable to be used with the provided abrasive tools. Main features and benefits: The abrasive tools for satin finish machines allow operators to work on quite large areas (from 50 to 100 mm in width) with a lightweight compact machine that can be used “freehand” even on parts already in place. The abrasive tool is efficiently driven by means of a unique split pin system. Recommended applications: Stainless steel, standard or alloyed steel, nonferrous metals and alloys, aluminium, cast iron, titanium, plastic, paint, varnish, filler, stone or wood. Work surfaces: Production and maintenance of machinery and equipment for the chemical, pharmaceutical, medical and food industries. Steel and stainless steel fittings such as cookers, extractor hoods, hobs and domestic appliances.

Request for a quote

BIBIELLE S.P.A.

Italy

These RG aluminium oxide flap wheels are characterized by extremely compact design, 3-mm diameter cylindrical shaft and X-Flex weight backing. Main features and benefits: Being very compact, our Micro RG wheels can be used in confined spaces. The small shaft diameter allows them to be used on light and versatile machine tools. Recommended applications: Finishing moulds, small-sized pipes and cylinders, drilled parts in general. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic materials, glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

These RG aluminium oxide flap wheels are characterized by extremely compact design, 3,17 mm diameter cylindrical shaft and X-Flex weight backing. Main features and benefits: Being very compact, our Micro RG wheels can be used in confined spaces. The small shaft diameter allows them to be used on light and versatile machine tools. Recommended applications: Finishing moulds, small-sized pipes and cylinders, drilled parts in general. Work surfaces: Stainless steel, standard steel, alloyed steel, aluminium, titanium, nonferrous materials and alloys, plastic materials, glass fibre.

Request for a quote

BIBIELLE S.P.A.

Italy

BCW Metal Finish Convolute Wheels Main features and benefits: The dense and durable, but still open web and the strong resin allow uniform finishing but also light deburring operations without changing the dimesions of the workpiece. Long life, extremely consistent finishing, high stock removal, conformability to the worked piece and cool running. Recommended applications: Generates uniform distinct satin, cosmetic, brushed and antique finishes. Blend machine tool marks and apply final finish, blend coated abrasive scratches while applying a burr-free finish acceptable for coating and polishing in one step. Can be used for light deburring applications, removing discoloration from welds, general purpose cleaning, removing rust.

Request for a quoteResults for

Finishing tools - Import exportNumber of results

26 ProductsCountries

Company type

Category

- Machine tools, cutting - parts and accessories (5)

- Grinding - machine tools (2)

- Labels, clothing (2)

- Cylinders, hydraulic (1)

- Hand tools, non-power (1)

- Industrial tools (1)

- Machine tools - metal machining (1)

- Magnets (1)

- Paper - Printing - Machines & Equipment (1)

- Plaster and plaster products (1)

- Polishing equipment and materials (1)

- Purses, leather (1)

- SMALL METAL PARTS (1)

- Sawing machine tools (1)