- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling of cans

Results for

Filling of cans - Import export

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The can weighing and filling machine for liquid, can be both automatic and semi automatic, the automatic one is a inline type and multi heads from 2 heads to 12 heads depends on the capacity demand;the semi automatic one normally is with nonzzles numbers from 1 to 2. Application It is application for Food and beverage, cosmetics and personal care, agricultural, animal care, pharmaceutical, and chemical industries.,Also used in jelly, pudding, fruit juice, ice cream cup filling, yogurt cup filling, honey, curd, buttermilk filling, and shrimpkhand filling with a single or double filling nozzles. It suits for filling multi liquids, low investment, easy cleaning.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Net weight filling machines use a weigh scale platform to monitor the weight of product as it is filling into a bottle or container. Net weight fillers are well suited for large container filling applications. This type machine is used for 5kg -30 kg,and 50KG to 300KG, and IBC system liquid filling. both of gravity filling or pump feeding liquid system with weight scale under filling nozzle or under the conveyor to assure filling accuracy. It can finish a series of operations automatically, such as bottle inlet, weight filling, and bottle outlet. Especially for SL, edible oil lubrication. it is a nice choice for foodstuff, pharmacy, cosmetic and chemical industries.Linear type machine, can be made with 2/4/6/8 filling nozzle for different filling capacity.

Request for a quote

ARPA INCORPORATED COMPANY

Greece

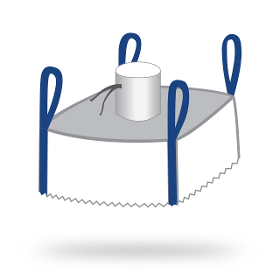

A top panel and cylinder attached to the upper body of the bag. The filling spout provides for clean and controlled transfer of material from the filling equipment to the bag. After filling, the spout can be tied off with pre-attached ties.

Request for a quote

TECNOCOSMETICA - COSMETIC PRODUCTS MANUFACTURER

Portugal

Tecnocosmetica does full service cosmetic production in Private label, Contract manufacturing and White Label according to ISO 22716 - GMP (Good Production Practices) Our production equipment and processes are versatile and can be adapted to different forms of manufacturing. Our filling machines work with a broad spectrum of preparations: liquids, gels, scrubs, creams, oils, butters, O/W and O/A emulsions, micronized suspensions, etc. Our specialized technology can be used for a wide range of skin care products, regardless of their density and viscosity. Our dedicated filling lines can be set up for automatic or semi-automatic filling. We also adapt to various types of packaging, such as tubes, jars and bottles made of plastic, glass and aluminum. All cosmetics from our production lines and are submitted to a rigorous quality control inspection. Quality assurance is key when producing cosmetic products. The quality assurance and quality control team

Request for a quote

KELTEKS

Croatia

kelteks Needled Fabric gives a finer appearance to the outer surface and when cutting into strips they do not fall off. Serves to strengthen the laminate and it is used for the first layer of laminate or for filling laminate. We can produce widths from 125cm up to 300cm and in roll length from 50m up to 500m

Request for a quote

KELTEKS

Croatia

kelteks Needled Fabric gives a finer appearance to the outer surface and when cutting into strips they do not fall off. Serves to strengthen the laminate and it is used for the first layer of laminate or for filling laminate. We can produce widths from 125cm up to 300cm and in roll length from 50m up to 500m

Request for a quote

PEMAT S.C.

Poland

Brand new gas Cylinder full of Argon 4.8 The cylinder is filled with a high quality 99,998% Argon welding compound. A protective cap protects the valve from damage during transport or storage. The cylinder is new and has a working pressure of 150 bar. The cylinder and valve are manufactured according to EN 1964:1999 and have the conformity mark π (pi) with the requirements of ADR / RID. ATTENTION! Our cylinders have a threaded valve (W21.8x1 / 14) and it is technically possible to fill it. However, filling problems can occur in certain countries such as France, Great Britain due to the type of valve used (G5/8") or Finland (W24,32x1/14) However, filling is possible without problem in most countries. TECHNICAL DATA CYLINDER GAS: Valve: 21.8 x 1/14 DIN 477 Content: 99.998% Argon Capacity: 8l Working pressure: 150 bar Quantity of gas: ~1.5m3 Height: 82 cm Diameter about: 14 cm Weight: ~13 kg Can be used throughout the European Union without additional testing for 10 years Powder coated according to current standards PN-EN

Request for a quote

PEMAT S.C.

Poland

Brand new gas Cylinder full of Argon and Carbon Dioxide mixture – Ar/CO2. A protective cap protects the valve from damage during transport or storage. The cylinder is new and has a working pressure of 150 bar. The cylinder and valve are manufactured according to EN 1964:1999 and have the conformity mark π (pi) with the requirements of ADR / RID. ATTENTION! Our cylinders have a threaded valve (W21.8x1 / 14) and it is technically possible to fill it. However, filling problems can occur in certain countries such as France, Great Britain due to the type of valve used (G5/8") or Finland (W24,32x1/14) However, filling is possible without problem in most countries. TECHNICAL DATA: Valve: 21.8 x 1/14 DIN 477 Content: Argon (82%) + CO2 (18%) Capacity: 8l Working pressure: 150 bar Quantity of gas: ~1.5m3 Height: 82 cm Diameter about: 14 cm Weight: ~13,5 kg Can be used throughout the European Union without additional testing for 10 years Powder coated according to current standards PN-EN

Request for a quote

PEMAT S.C.

Poland

Brand new gas cylinder full of Nitrogen. The bottle contains 8 liters of high quality pure NITROGEN, designed for e.g. checking the tightness of various types of valves, air conditioning, and pumping wheels. The cylinder is new and has a working pressure of 150 bar. The cylinder and valve are manufactured according to EN 1964:1999 and have an ADR / RID compliance mark and a -40°C mark. ATTENTION! Our cylinders have a threaded valve (W24.32x1 / 14) "RH and it is technically possible to fill it. However, filling problems can occur in certain countries such as France, Great Britain, Finland. due to the type of valve used. However, filling is possible without problem in most countries. TECHNICAL DATA: Valve: W24,32 x 1/14 "RH Content: Nitrogen Capacity: 8l Working pressure: 150 bar Quantity of gas: ~1.6m3 Height: 82 cm Diameter about: 14 cm Weight: ~14 kg Can be used throughout the European Union without additional testing for 10 years Powder coated according to current standards PN-EN

Request for a quote

SYNERLINK

France

Our RM25B bottle filling machine for preformed bottles is known for its extremely high filling accuracy. We can also deliver a wide range of decontamination levels according to shelf-life need and storage conditions. This machine's compact footprint and cost-efficiency are ideal for small beverage lines. Our equipment is designed to make all operations at ground level. The filling volume goes from 80 to 270 ml at a speed up to 6,000 bottles per hour. Our machine can handle various materials (PET, HDPE, PP, PS) with optional screw capping. With one or two neck diameters, 40 to 56mm body diameter and multi-flavors filling, RM25B is optimal for industries where flexibility and line efficiency are critical.

Request for a quote

SYNERLINK

France

Our RM12B bottle filling machine for preformed bottles is known for its extremely high filling accuracy. We can deliver a wide range of decontamination levels according to shelf-life need and storage conditions. This machine high flexibility and technical efficiency are ideal for medium beverage lines. Our equipment is designed to make all operations at ground level. The filling volume goes from 80 to 1,000 ml at a speed up to 50,000 bottles per hour. Our machine can handle various materials (PET, HDPE, PP, PS) with optional screw capping. With one or two neck diameters, 40 to 92mm body diameter and multi-flavors filling, RM12B is optimal for industries where flexibility and line efficiency are critical.

Request for a quote

SYNERLINK

France

Our RM80B bottle filling machine for preformed bottles is known for its extremely high filling accuracy. We can deliver a wide range of decontamination levels according to shelf-life need and storage conditions. This machine compact footprint and cost-efficiency are ideal for medium beverage lines. Our equipment is designed to make all operations at ground level. The filling volume goes from 80 to 1,500 ml at a speed up to 24,000 bottles per hour. Our machine can handle various materials (PET, HDPE, PP, PS) with optional screw capping. With one or two neck diameters, 40 to 88mm body diameter and multi-flavors filling, RM80B is optimal for industries where flexibility and line efficiency are critical.

Request for a quote

SYNERLINK

France

The COMBI adds value to any complete PET packaging line by combining blow molding, filling and capping into an integrated system. By eliminating conveying, empty bottle handling, accumulation and storage, the COMBI optimizes line layout with a linear compact footprint, improving production hygiene and efficiency while lowering operating costs. Our brand of filling equipment with blowing unit can be used for dairy products, as well as fruit juices, smoothies, nutritional drinks, coffees and teas, presented in PET. Express your creativity! Nearly anything is possible, from one-of-a-kind bottle shapes and decorations to unique over caps above screw caps, thanks to our various options

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Quantitive the liquid weight by a high quality weigher and weigher sensor High accuracy measurement system for different types of non corrosive liquid, corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need.

Request for a quote

FERPLAST SNC

Italy

The idle roller with boxes-stopper plan allows the operator to "lock" the box still to be closed and make the filling operations. Depending on customer requirements can be matched more filling stations. For safer packaging, especially of fragile goods such as glasses, bottles and cosmetics, it is also possible to place beside the operator a machine to create air cushions.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

For some highly corrosive liquid products, this machine can adapt PTFE pump, PTFE hose and sealing material, so as to avoid the corrosive of the machine 2. The parts in contact with the liquid conform to the GMP standard. When filling, the filling head extends into the bottle and the bottle is sealed to ensure that the liquid does not foam and overflow, and the liquid level in the bottle is consistent. 3. The filling head has the function of sucking back, and there is no dripping phenomenon. The bottle is not in place and not filled, ensuring misoperation and keeping the work area clean. 4. This machine has only one filling pump, one top tank and one side stand tank which can be equipped with 2~20 filling heads, and the output and filling volume can be adjusted if need. More information: When filling, the filling head presses against

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Volumetric by a high quality piston High accuracy measurement system for different types of non corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable, and by the distance of the piston working stroke The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need. Pharmaceutical, GMP,FDA health standards. Hard, abrasion resistant, particle release is extremely small, long service life. Dense material, water absorption as low as zero; very high surface finish, minimal friction; therefore minimal residual materials. Thermal expansion coefficient is small, piston clearance fit more, filling accuracy can be achieved online cleaning and sterilization.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

It is PLC control the flowmeter open and shut off, servo motor driven the filling nozzles moving up and down. Capacity: The capacity of an automatic flowmeter filling machine can vary depending on the model, but typically ranges from 500 ml to 5 liters. Material: Most flowmeter filling machines are made from stainless steel or other food-grade materials to ensure the quality and safety of the product being filled. Speed: The speed of the filling process can be adjusted depending on the viscosity of the liquid and the desired fill volume. Typically, these machines can fill between 30 and 60 bottles per minute. Accuracy: Flowmeter filling machines are known for their high level of accuracy in measuring the volume of the liquid being filled. They can achieve accuracy levels of +/- 0.5%. Operation: The operation of an automatic flowmeter filling machine is typically

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

The sturdy stainless steel and impact-resistant plastic housings are designed for mounting on tubs or similar containers. With the stainless steel brackets on the rim of the tank, the fill level can be easily adjusted. The fill level can also be finely adjusted on the PEKI brass high-performance float valve for high and low pressure. Stepless adjustment, simple installation, low wear, long service life and safe operation of the autotanker for automatic filling.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

All pipe use quick-change connector. 2. Height and space between filling heads can be changed quick and easy to operate. 3. All filling valve use ESG valve instead of traditional valve by general manufacturer. 4. All filling heads can be diving from the bottom of bottle to start filling. Features 1.1 Suitable material: Wine, beverage,vinegar, daily chemical and something that are low viscous,especially for the foamy liquid. 1.2 This Vertical filler is a high-tech filling equipment integrating on the PLC microcomputer programmable control, and photo electricity instruction pneumatic action. 1.3 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes. Short filling circle, high production capacity. 1.4 User may choose the filling volume and decide the filling heads per own production capacity. 1.5 The precision time of the pneumatic valve filling may set to 0.01

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machines are made of high-quality stainless steel, making them durable and easy to clean. 6. Automatic control: Liquid weighing filling machines have automatic controls that detect when the container is full, stopping the filling process. 7.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

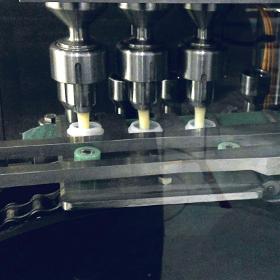

The NP-EVF economy automatic horizontal piston filler is equipment with 2 or 4 filling heads,the driven system can be air cylinder or a servo motor. Feature 1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machi machines are made of high-quality stainless steel, making them durable and easy to clean.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

An automatic flowmeter filling machine is a type of equipment used in the packaging industry for accurately filling liquid products into bottles or containers. It uses a flowmeter to measure the volume of the liquid being filled and automatically stops the filling process once the desired volume is reached. Feature: It is PLC control the flowmeter open and shut off, servo motor driven the filling nozzles moving up and down. Capacity: The capacity of an automatic flowmeter filling machine can vary depending on the model, but typically ranges from 500 ml to 5 liters. Material: Most flowmeter filling machines are made from stainless steel or other food-grade materials to ensure the quality and safety of the product being filled. Speed: The speed of the filling process can be adjusted depending on the viscosity of the liquid and the desired fill volume. Cleaning: Flowmeter filling machines are designed to be easyto clean, with quick-release fittings and removable components

Request for a quote

MINEBEA INTEC GMBH

Germany

The weight controllers CSD-912 and CSD-918 ensure simple dosing and filling applications, can manage up to 10 materials and execute different dosing modes. CSD-912 benefits Material management and dosing in one weighing controller Weight value analysis at a glance Intuitive operation via touch display Time-saving configuration CSD-918 benefits Enables additional measurement of feeding and discharging

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Semi automatic Pneumatic volumetric Piston Filling machine is available with Single Head or double filling Heads.High quality and famous brand air cylinder ensure the machine work stably and fast.Make the machine suitable for fill viscosity and liquid.This semi-auto machine have 2 working mode for operation,auto and pedal. Feature Volumetric by a high quality piston High accuracy measurement system for different types of non corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable, and by the distance of the piston working stroke The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need. Pharmaceutical, GMP,FDA health standards. Hard, abrasion resistant, particle release is extremely small, long service life.

Request for a quote

PEEKCHINA CO., LTD.

China

Manufacturing Process CNC Machining & Injection Molding Glass Filled PEEK Thermal Properties High Operating Temperature: Glass-filled PEEK can withstand temperatures up to 250°C (482°F). Low Thermal Expansion: It has minimal dimensional changes with temperature. Low Thermal Conductivity: It's a poor conductor of heat, useful for insulation. Flame-Resistant: PEEK is inherently flame-resistant with low smoke emissions.

Request for a quote

KULLEN-KOTI GMBH

Germany

Kullen-Koti has a large range of moulded brush discs. These are used for various applications, namely, de-burring. For this, brush discs with nylon abrasive filling or wire are mainly used. The abrasive filling removes burrs that occur during production processes. Moulded disc brushes are characterised by their filling density. This can´t be achieved with other brushes. Furthermore the moulded disc brush has an extra flat filling. That leads to perfect deburring results and has a longer service life than conventional brushes. They need to be replaced much less frequently. The brush discs are available in diverse dimensions and materials. They can be provided with a bore with or without a keyway. There are other connecting possibilities, such as nuts and cams. Besides abrasive filling and wire, all available filling materials can be used.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-OF Automatic Multy Head Overflow Liquid Filling Machine works by feeding the liquid through a specific pump or a top storage tank. Simultaneously, once the feeding is completed, a portion of the material returns to the liquid overflow tank via the overflow port to guarantee the filled bottle in same level. The depth of the overflow port in the container neck determines the container’s filling level, which is easily adjustable. The number of filling heads can be increased to meet production needs. It’s ideal for filling low-viscosity, high foamy liquid in the chemical, food, pharmaceutical, and other sectors. Vacuum overflow filler system is for optional,filling nozzles moving up and down by servo motor driving, specially designed overflow filling nozzles.

Request for a quote

PEKU FOLIEN GMBH

Germany

One side of the flap bags is longer than the other, so that the bag, after filling, can be closed by turning the flap. Furthermore, the flap ensures a quick and easy filling of the shipping bag. We would be pleased to give you advice about our flap bags. We look forward to your inquiry by mail or by phone: +49 (0)9181/2960-0!

Request for a quoteResults for

Filling of cans - Import exportNumber of results

180 ProductsCountries

Company type

Category

- Bottling and filling - machinery and equipment (43)

- Packing and packaging - machinery and equipment (9)

- Engines & Parts (7)

- Food Industry - Machines & Equipment (6)

- Metal brushes (6)

- Cosmetics (5)

- Food industry packaging machinery (4)

- Bags, plastic (3)

- Chocolates, filled (3)

- Gas, compressed (3)

- Labelling machines (3)

- Parasols (3)

- Beauty products (2)

- Bottles and jars, plastic (2)

- Bread & Cakes (2)

- Explosion-proof - equipment (2)

- Fabrics for technical use (2)

- Flour and semolina (2)

- Plate glass and mirrors (2)

- Bag filling machinery and equipment (1)