- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fiber placement

Results for

Fiber placement - Import export

TFP TECHNOLOGY GMBH

Germany

We offer our innovative fiber laying technology to produce customzied fiber preforms without any waste and in a very efficient way - multi - layer - technology. Especially for complex shapes and forms with locally reinforcements it is the best choice. More efficient than carbon weave or automatic fiber placement (AFP). The elements made form endless fibers have better performance than 3-D-printed parts of carbon, too. Please contact us for a first trial!

Request for a quote

BORFLEX SERVICES

France

BORFLEX® has developed elastomer rollers for fibre placement to meet the various needs of customers while adapting to new technological advances. These fibre placement rollers are produced from specific materials, developed and tested by our R&D teams. We offer a wide range of AFP rollers, which, depending on your processes and materials used, will meet all your requirements. FIBERROLL® by BORFLEX® rolls come with a wide range of options, allowing you to create rolls to suit your image: colour, marking, packaging, etc. Our teams are on hand to help you develop your technologies, from the trial phase to mass production.

Request for a quote

TFP TECHNOLOGY GMBH

Germany

With our CNC-fiber laying technlogy we can manufacture carbon preforms up to 2500x2000mm. That way producing composite parts in large dimensions will not be a problem. The usage of different fibers (carbon, glass and aramid) is possible too. Please contact us.

Request for a quote

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

Integrated Photonics is all about our equipment for high-precision positioning of Photonic Integrated Circuits (PICs), enabling you to optimize your back-end processes and reduce your costs. Our fiber array unit combines the latest technologies on automatic fiber placement. Our Photonic Test Prober (PTP) and Photonic Visual Inspection Tool (PVIT) are part of the MEKOPP project.

Request for a quote

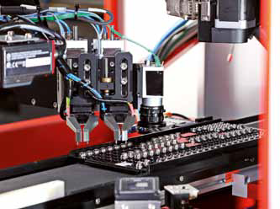

NANOSYSTEC GMBH

Germany

The fully automated assembly station VersaGlue takes components, such as lenses or dies from a loading area and mounts them by epoxy gluing with UV or thermal curing. The large work area of up to 1000 mm x 1000 mm provides space for the positioning of device trays and support systems. The parts are presented manually or fully automated. Feeders or stop-motion conveyor belts bring the parts to the working area and collect the finished product. The VersaGlue processes optoelectronic elements like VCSELs, photo diodes, laser dies and micro optics with highest precision while the passive placement of fiber ribbon cables is another major application.Thorough design and continuous optimization of all functional groups lead to superior mechanical stability. Mechanical references with tight tolerances provide a repeatable manufacturing operation from device to device.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Fiber placement - Import exportNumber of results

5 ProductsCountries

Company type