- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fem calculation

Results for

Fem calculation - Import export

DGS DRUCKGUSS SYSTEME AG

Switzerland

Perfect die-casting components are not the only strength of the DGS brand. As a process-oriented full-service partner we offer numerous complementary services to our customers. In our development department we work with state-of-the-art CAD and CAM equipment, which enables us able to perform client-specific FEM calculations and complete die-casting process simulations. To ensure the best possible production efficiency, we are in contact with our client’s experts in the early stages of design and prototyping, a collaboration which continues after the casting process. Our know-how goes far beyond quality checks and logistics; in many cases we take over the responsibility for development, surface finishing, shot peeling, machining, galvanising, coating, painting and the assembly of parts and systems. The result from the client’s point of view: less interfaces and more time for essentials.

Request for a quote

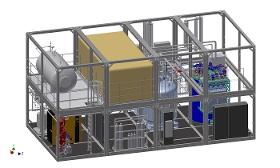

KASAG SWISS AG

Switzerland

We bring your ideas to life KASAG has a high level of competence, with many years of experience in design and construction of plants, apparatuses, pressure vessels, pipes and welded structures. Our engineers can assist you with the following: Strength calculation according to the global regulations, such as PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) FEM-calculations (Finite element analysis) and providing proof for overpressure and underpressure, load alteration, earthquake, joint flanges, nozzle loads Consultancy for interpreting and analyses of computation results, material choice, regulatory authorities Constructive, design based on Autocad 2D and Inventor 3D Comprehensive plants engineering, such as compilation of technical specifications, P&I schemes, risk analyses, pipeline/piping planning

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

Roof rim for trams in Karlsruhe When manufacturing and attaching the roof rim for trams in Karlsruhe, it was particularly important to ensure that the adhesive bond was secure. These dualsystem vehicles, which are manufactured by Bombardier, can reach speeds of up to 100 km/h. The GRP roof rim was attached to the vehicle body using an invisible aluminium bracket. The adhesive bonds between the aluminium and GRP were applied in accordance with DIN 6701, Class A1, and thoroughly tested in conjunction with the Fraunhofer Institut. FEM calculations demonstrate the permanent durability ofthe adhesive bond.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The optimum oscillation behavior of the ultrasonic sonotrodes is determined by means of FEM (Finite Element Method) calculation. Highest precision requirements in terms of CAD/CAM calculation algorithms guarantee precise 3D contours for sonotrode manufacturing. Measuring and documentation of the amplitude distribution is performed at the vibrating sonotrode using state-of-the-art laser measurement technology. Special surface finishings result in even longer service life spans of the ultrasonic sonotrodes.

Request for a quote

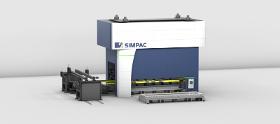

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 3,000 - 10,000 kN ● Part size: small to medium ● Slide kinematics: servo (freely programmable) ● Application: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes through the use of torque motors that provide high torque even at low speeds ● Maximum production flexibility due to freely programmable slide movement, slide velocity and stroke length ● Significantly higher output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 8,000 - 30,000 kN ● Part size: medium to large ● Slide kinematics: servo (freely programmable) ● Applications: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes thanks to the use of torque motors that deliver high torque even at low speeds ● Maximum production flexibility through free programmability of slide movement, (forming) speed and stroke lenths ● Significantly more output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

Compact and modular presses for a wide range of medium sized parts. Flexible installation options as a single press in progressive or transfer mode or as fully automated press line. Overview: ● Pressing capacity: 3,000 - 10,000 kN ● Component size: medium ● Slide kinematics: crank ● Applications: stamping, cutting, forming, bending, embossing Features and benefits: ● The compact design requires little floor space and no foundation at presses below 4,000 kN. ● The very solid, low-stress annealed press bodies are FEM-calculated and optimized by so-called “hot-spot analysis” in areas which are subject to higher loads. ● Motor, clutch/brake unit, lubrication system and control are of German origin and guarantee a long service life and maximum dynamics. ● The slide guiding system ensures a high level of tilting rigidity and reduces the cutting impact during the cut through when it comes to the processing of higher-strength materials.

Request for a quoteResults for

Fem calculation - Import exportNumber of results

8 ProductsCountries

Company type