- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- feeders for belts

Results for

Feeders for belts - Import export

NOVELTY STEEL

Turkey

A screw feeder is primarily designed for handling very low-tonnage outputs, with a critical requirement for positive and controlled material discharge. This type of feeder offers the advantage of easy enclosure, making it effective at preventing the release of dust. Consequently, it allows for a sealed hopper and chute arrangement from the hopper to the delivery point. The basic structure of a screw feeder includes a helical screw that rotates below the hopper outlet and is driven by an external power source. The screw can have a fixed pitch or a variable pitch with smaller spacings in the rear and gradual increases in pitch towards the discharge end. This design ensures that the material moves efficiently within the rear portion of the hopper. Novelty Structures supplies various type of Feeders for Mineral Processing Plants. * Belt Feeders * Screw Feeders * Apron Feeders * Rotary Table Feeders

Request for a quote

NOVELTY STEEL

Turkey

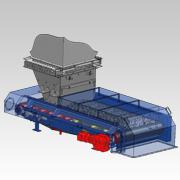

A belt feeder is comprised of an uninterrupted rubber belt that is supported by closely spaced idlers and propelled by end pulleys, commonly known as the head and tail pulleys. This entire assembly is enclosed within a single framework. The motor can be installed on the ground or on a separate frame and drive the feeder through the use of V-belts. Typically, the belt feeder is positioned beneath a hopper with a long, narrow slot-like opening. It allows the material to be fed along the length of the hopper. Belt feeders typically come in a range of widths from 0.6 to 1.8 meters and lengths spanning from 1.5 to 4.6 meters. The capacity of a belt feeder is determined by the width of the belt and the speed at which it moves. In practice, the capacity of belt feeders generally falls within the range of 4.5 to 2,270 tons per hour. Novelty Structures supplies various type of Feeders for Mineral Processing Plants.

Request for a quote

SPF SWEDA LTD

Ukraine

The belt feeder (weight belt batcher of continuous operation) SWEDA DWL is designed for continuous batching with a given capacity of bulk and lumpy materials. Features: - Accurate maintenance of the specified capacity (±0,5%); - Execution for the width of the conveyor belt from 500mm to 1200mm, the length of the conveyor from 2m to 6m, the temperature range of the dosed material up to 200 ° - Wide range of batcher capacity; - Equipped with a needle or knife gate; - Use of components from leading world producers; - Data output to a remote display and a computer as part of the process control system; - The batcher can be equipped with a special device for its dynamic calibration. We are in social networks: Facebook: https://www.facebook.com/SPFSwedaLtd Instagram: https://www.instagram.com/easyweighing/

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Stable dust-tight design for harsh industrial conditions — Removable doors for quick cleaning — Usable as a continuous or batch-wise metering belt feeder or for throughput metering (operating mode can be changed on the controller) Power range 200-50000 dm³/h

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK UMBB Series Vibrating Feeders are positioned in the intermediate stock points, at the exit of the silo or bunker where the material is stocked, in order to ensure continuous feeding of the machines at all stages after the primary crushing stage in crushing and screening processes.

Request for a quote

FEMIA INDUSTRIE

France

Cuts husked ears of corn. Capacity of 110 ears/minute. Machine primarily comprised of a feeder belt and a rotating bowl that allows for transfer of cobs on a corn belt one after the other and correctly aligned, of an automatic “head first” orientation system of the ears and of a cutting head comprised of 6 blades arranged like a diaphragm of a camera. The orientation system is also capable of “diverting” ears that are too short. Self clearing of the cutter head is case of jams. The cutter requires the dedicated WKS blade sharpener.

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

Whether for large or small conveyed quantities, no matter the application, from luxury food processing to the steel industry, AViTEQ Belt weigh feeders assure high weighing precision for reliable, uninterrupted operations. In automated production processes requiring constant weighing and metering, Weiteq Belt Weigh Feeders are the first choice. Advantages and benefits For feeding a wide range of bulk materials from free flowing to bridging High long- and short-term accuracy Robust construction allows ease of installation and belt replacement Customized feeder sizes, belt type and feed hopper based on bulk material handling experience Special solutions for high-accuracy feeding and heavy duty operating condition Can be used with different types of feeding equipment and directly at the silo outlet Application Components feeding for blending Feeding of additives Batch charging Wagon and truck loadingFeeding and control systems for mills, crushers and mixers Technical data WBL-L WBF-M W

Request for a quote

NOVELTY STEEL

Turkey

Apron feeders come in varying widths, ranging from 0.6 to 3.0 meters, and lengths spanning from 2.4 to 30.5 meters. Lengths exceeding 4.6 meters are primarily used for material conveyance rather than being an integral part of the feeder. Apron feeders exhibit capacities ranging from 91 to 2,270 tons per hour. The power requirements for apron feeders are approximately twice as high as those for comparable belt feeders. Apron feeders are typically employed in situations involving truck dumps or other scenarios where very coarse materials are handled, such as in the feeding of primary or secondary crushers. When an apron feeder is intended for use under a truck dump hopper with an elongated hopper opening, it’s essential to design the hopper with a taper that widens in the direction of horizontal flow for belt feeders. Novelty Structures supplies various types of feeders such as; * Apron Feeders * Belt Feeders * Rotary Table Feeders * Screw Feeders

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

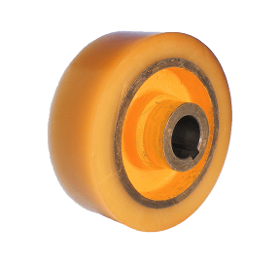

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Harbs rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. We would be pleased to advise you on which harbs rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Gubisch rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core receiving hole is designed with a feather keyway. We would be pleased to advise you on which gubisch rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Wood-Her rollers consist of an aluminum core. Light-colored rubber is used for the coating, in addition to the polyurethane materials that have long been tried and tested in the woodworking industry, and mainly the elastomer Vulkollan®. The core mounting holes have two side holes.As a service, we offer our customers the opportunity to have their used pressure and feed rollers re-upholstered by us. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design in smooth or grooved form and the most suitable degree of hardness must be determined by the customer. Weinig rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core mounting holes are designed as a keyway or with three side holes.The Weinig rollers are mainly coated with the elastomer Vulkollan® patented by Bayer. We would be happy to advise you by telephone or at your location regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for bulk handling projects. With our modern CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke steel frames according to the EN 1090-2 European Norms. Some examples of the bulk material structure fabrications are : Steel frame for Conveyor Belts Feeders Transfer Towers Bunkers Hoppers Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

STATEC BINDER GMBH

Austria

Our product portfolio includes three manual bagging machines for open-mouth bags: SCALPAC-G, SCALPAC-B, SCALPAC-S. All three bagging systems are designed for up to 1200 bags per hour and differ only in the used net weighers. Depending on the product to be filled, a net weigher with gravity, belt or screw feeding is used. Prefabricated open-mouth bags made of woven PP, PE or paper are attached to the filling clamp and fixed by an employee. As soon as the bag is fixed, the weighed product flows into the bag. A conveyor belt transports the filled bag to a bag closing machine, which sews, seals or hot-glues the bag depending on the material. For free-flowing bulk materials, a net weigher with gravity feeding is selected. Moderately flowing products are fed via a belt feeder. For fine and powdery products, the screw feeder is best suited.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for bulk handling and mining projects. With our modern CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke steel frames according to the EN 1090-2 European Norms. Some examples of the bulk material structure fabrications are : Steel frame for Conveyor Belts Feeders Transfer Towers Chutes Hoppers Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for bulk handling projects. With our modern CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke steel frames according to the EN 1090-2 European Norms. Some examples of the bulk material structure fabrications are : Steel frame for Conveyor Belts Feeders Transfer Towers Bunkers Hoppers Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

PRESSTA EISELE GMBH

Germany

High-Performance automatic circular saw for aluminium and non-ferrous heavy metal Fully automatic operation Use of TCT or solid carbide blades ø 250 mm Motor 7,5KW, 400 V, 50 Hz, infinitely adjustable Blade feeder hydropneumatic Material feeder with ball screw spindle and servo motor 2-axis NC control Simatic S7-300 with 7“ touch screen Cutting range: height up to 60 mm, width up to 140 mm Manual safety cover 2x Ø 100 mm swarf extraction connector Blade feeder pneumatic hydraulic controled vertical top to down Manual blade feed adjustment to optimize the feed length Pneumatic clamps horizontal left and right of the blade Diagnosis of errors, trouble shooting Pneumatic clamps vertical left of the blade Mist spray blade lubrication (filling level controlled) 1 l tank Parts slide (Option: conveying belt) Material feeder from 2 – 650 mm with ball screw spindle and servo motor Multiple material feed possible up to 3250 mm cutting length Vertical and horizontal clamps Reducer of...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ENVEA

France

Sensor for continuous moisture measurement in dry bulk solids and installation on conveyor belts, screw feeder or hoppers. Microwave based sensor for high resolution and accuracy. • highly resistant to abrasion • extended measurement range, up to 85 % moisture • high temperature version up to 190 °C • measurement accuracy 0.1 % • recording of surface moisture and capillary moisture

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— RS 485 interface for internal Brabender fieldbus — Application software for DDW (loss-in-weight feeder), DBW (dosing belt scale) or Coriolis flow meters — internal pluggable fieldbus connection — can be controlled via the OP1, OP6 and OP16

Request for a quote

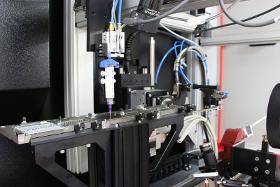

NANOSYSTEC GMBH

Germany

VersaHybrid is a semi or fully automated production system for complex assemblies which require a precision in the low micrometer regime. Assembly techniques include micro welding, selective laser soldering and gluing plus laser fine cutting. Various processing methods are combined in one station. Feeders, belts and robots allow for full automation.

Request for a quote

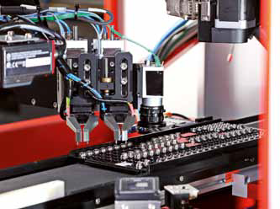

NANOSYSTEC GMBH

Germany

The fully automated assembly station VersaGlue takes components, such as lenses or dies from a loading area and mounts them by epoxy gluing with UV or thermal curing. The large work area of up to 1000 mm x 1000 mm provides space for the positioning of device trays and support systems. The parts are presented manually or fully automated. Feeders or stop-motion conveyor belts bring the parts to the working area and collect the finished product. The VersaGlue processes optoelectronic elements like VCSELs, photo diodes, laser dies and micro optics with highest precision while the passive placement of fiber ribbon cables is another major application.Thorough design and continuous optimization of all functional groups lead to superior mechanical stability. Mechanical references with tight tolerances provide a repeatable manufacturing operation from device to device.

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

Equipment features: - Simple and easy operation - Processing of logs by sawing and splitting in one pass - Automatic removal of the material by means of a belt conveyor - Powerful 9.5kW electric motor for fast work even with larger logs with 50cm diameter - Hydraulic chain saw and log holder operation for even more fatigue-free work - Integrated hydraulic feeder belt to supply the saw blade machine with material Delivered without fluids Technical data: Feed conveyor belt (LxW): 2150 x 250 mm discharge conveyor belt (LxWxH): 3200 x 200 x 2200 mm Conveyor belt speed: 0,5 m / sec. Own weight incl. conveyor belt: 780 kg (670kg + 110kg) Packing dimensions automatic saw blade machine (LxWxH): 2000 x 1000 x 1200 mm Packing dimensions discharge conveyor (LxWxH): 1850 x 450 x 570 mm Packaging dimensions infeed conveyor (LxWxH): 1150 x 680 x 380 mm chain (STIHL): C3621 000 0077/0.375/1,5mm

Request for a quote

TECONER OY

Finland

The sensor is used to measure the moisture of concrete aggregates and is typically installed over a silo belt feeder or a conveyor belt or under a silo trap door to have a view on a moving sample. Current loop is available for feeding the data into your PLC, and a software licence for a PC to calibrate the sensor as well as view and store the data is also included in the system. There are no moving or wearing parts and as the measurement is done by a non-contact remote sensor, the maintenance cost will be very low.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Belt feeders are recommended for the extraction and dosage of aggregates from hoppers, ensuring a constant and regular flow rate with small and medium size aggregate, in cluding in the presence of high percentages of fine matter. They are usually mounted with variable speed motors and/or inverters for fine adjustment of the speed of extraction and the flow rate.

Request for a quote

KESTASMAK MINING MACHINERY AND SPARE PARTS

Turkey

jaw crushers, primary impact crushers, secondary impact crushers, dewatering systems, screens, vertical shaft impact crushers, VSI, VSI spare parts, crusher wearing parts, feeders, bunkers, conveyor systems, conveyor belts, conveyor rollers, conveyor drums, belts, clamps, high carbon steel woven meshes, anti clogging, anti-clogging screen meshes, flex screens, perforated steel screens, bolts, polyurethane screens, polyurethane tensioned screen panels, polyurethane jig screens, polyurethane dewatering screens

Request for a quoteResults for

Feeders for belts - Import exportNumber of results

26 ProductsCompany type

Category

- Mining and quarrying - machinery and equipment (4)

- Cutting - steels and metals (2)

- Import-export - electrical and electronic equipment (2)

- Industrial tools (2)

- Measurement and regulation equipment and instruments - output and flow (2)

- Weighing and dosing equipment (2)

- Wheels, castors and rollers (2)

- Bridges, metal (1)

- Concrete preparing - machinery and equipment (1)

- Conveyor systems (1)

- Crushing and grinding machinery (1)

- Extraction machinery and equipment - minerals and ores (1)

- Packing and packaging - machinery and equipment (1)

- Sawing machine tools (1)