- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- feeder system

Results for

Feeder system - Import export

SACFORM/AGMLINE

Turkey

Decoiler-Straightener & Servo Feeder Systems are Designed on a Single Chassis to Minimize Space Need at Our Customers Production Facility. These Systems are Convenient for Various Purpose of Work and Desired Projects for The Metal Industry.

Request for a quote

TECHNIC MACHINES

Turkey

Our compact coil feeder and straightener machine is for custom solutions on press feeding equipment’s results with minimum necessary space solution. Also we are targeting to provide precision results on decoiler straightener and feeder machine's press feeding solutions. Our compact coil feeder is provide perfect results for press feeding process. Coil decoiler, straightener and feeder machines are manufactured as synchronised machine system and as single machine body for coil decoiler, straightener and feeder. Also straightener feeder has single body design on our compact coil feeder machine system. We provide compact coil feeder machine systems with custom solutions according to our customers final product needs. Such as with different thickness and width range and decoiler tonnage capacity.

Request for a quote

TECHNIC MACHINES

Turkey

Our coil feeder and straightener machine is for custom solutions on press feeding equipment’s results. Also we are targeting to provide precision results on decoiler straightener and feeder machine's press feeding solutions. Our coil feeder is provide perfect results for press feeding process. Coil decoiler, straightener and feeder machines are manufactured as synchronised machine system but separated or as single machine body for coil decoiler, straightener and feeder. We provide coil feeder machine systems with custom solutions according to our customers final product needs. Such as with different thickness and width range and decoiler tonnage capacity.

Request for a quote

ROBINSON CO.

Turkey

The cylindrical body structure is produced in a structure suitable for the product flow in one or both sides, depending on the project conditions, with supporting legs suitable for connecting to the floor deck or floor. The vibro feeding system connected to the conical structure has an adjustable flow flap and is driven by a vibromotor. In flour factories, it is used in the parts that require the adjustment of the ground grains at the appropriate flow and simple feeding, generally in the parts where the filter outlets need to feed a pneumatic line or a machine and where the dust wastes are brought into the system with pneumatics.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This feeder consists of a completely overhauled rotary feeder from CMC, a new pressure/vacuum pump made by Becker, and a self-programmed control system. All components are mounted on a stable frame made of aluminum construction profiles, which can be placed as a compact unit autonomously at any desired position in the production. The machine can either be operated continuously or controlled by an external signal. This allows inserts to be placed with pinpoint accuracy in a collecting section or at high speed on a conveyor belt to be addressed via inkjet, for example. We offer a 6-month warranty on parts and service for this machine. Our systems can be freely configured according to your needs. Tell us your requirements so that we can present a concrete solution proposal.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-LC automatic spindle capper is almost a universal capper, it is sutiable for capping screw caps, flip flop caps, spray caps, drops caps, metal caps, twist off caps. An automatic spindle capping machine is a device used to cap containers with screw-on caps. The machine works by placing the containers under a series of rotating spindles, which spin the caps onto the bottles or jars. The spindles are adjustable to fit different sizes and shapes of containers, and the speed can be adjusted for different production rates. The machine may also include features such as a cap sorter and feeder, a conveyor system to move the containers through the process, and controls to ensure proper torque and alignment of the caps. Automatic spindle capping machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and efficient capping is necessary for product safety and quality.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

width 66 cm age 2004 pallet feeder Tremat sheet-seperation system 6 folding pockets in the parallel fold section following knife shaft 2 folding knives in the cross fold section 1 additional folding pocket after the 1st cross fold control unit ACC 2.4 window folding pocket pneumatic stream delivery SAK 66 Delivery time: immediately Ref: HE230172A Please ask for price. We ship and install worldwide!

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

width 78 cm age 2001 pallet feeder Tremat sheet-seperation system 4 folding pockets in the parallel fold section following knife shaft 2 folding knives in the cross fold section noise absorbing hood folding knife unit VFZ 52.D stacking delivery SB 66 MP.D without compressors / air supply Ref: HE230275A Please ask for price. We ship and install worldwide!

Request for a quote

SACFORM/AGMLINE

Turkey

Servo Feeder with Straightener Systems, In Addition to Provide the Combination of Feeding and Straightening, Also Enables the Opportunity to Work Fast and Precise at High Performance Press Machines.

Request for a quote

TOMECH SOLUTIONS

Romania

Feeders are devices used to regulate and control the flow of bulk materials from a storage container or hopper to downstream processes or equipment. They play a vital role in ensuring a steady and controlled supply of material, enhancing the efficiency and productivity of material handling systems. Vibrating feeders are a type of feeder that utilizes vibrations to move materials along a trough or tube. Vibrating feeders are commonly used in industries such as mining, aggregate processing, and pharmaceuticals due to their ability to handle a wide range of materials and feed rates while minimizing spillage and dust emissions. We specialize in feeder design services, offering tailored solutions to optimize material flow, feed rate, and system performance. Our expertise encompasses the design, selection of feeder type, and integration of feeding equipment into material handling systems to meet the specific requirements of our clients and enhance their operational efficiency.

Request for a quote

ARINKO BAUTZEN GMBH

Germany

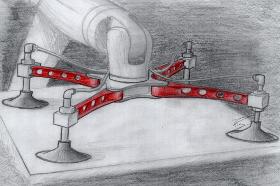

In cooperation with our system partners, we offer you various all-around solutions in the field of handling systems in plant engineering & conveyor technology. In addition to these complete solutions, we also take on the development of various plant parts and/or system components: Manipulators, grippers Transfer stations Safety equipment Workpiece carriers Control cabinets Peripheral equipment Podiums, stairs Media transfer Feeder systems Ejector systems Manual workstations Design focal points: Design & constructional drafts Use of pneumatic and/or electric drives Space-saving lifting stations Construction in accordance with relevant guidelines and regulations Static & dynamic calculation of the construction Material & weight optimization of existing and new systems Project planning to initial start-up of complete automation solutions Optimization and conversion of existing systems

Request for a quote

SACFORM/AGMLINE

Turkey

SACFORM Cut to Length Line consists of Decoiler, Servo Feeder with Straightener, Shear System and Stacking Units. With all these equipment, our Line is a feature-complete Turnkey Project for our Customers.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Meter feed directly to scrap metal furnace. Meter feed abrasive die scrap, casting metal, and other materials directly to the melting furnace. PRAB’s furnace feeder scrap removal systems allow you to meter feed abrasive die scrap casting metal and other materials directly to the scrap metal furnace.

Request for a quote

TIANJIN ZHONGHUAN ASCEND TECHNOLOGIES CO., LTD.

China

Air Dielectric cable used as feeder cable for broadcast transmitting system.

Request for a quote

TIANJIN ZHONGHUAN ASCEND TECHNOLOGIES CO., LTD.

China

Air Dielectric cable used as feeder cable for broadcast transimtting system.

Request for a quote

TIANJIN ZHONGHUAN ASCEND TECHNOLOGIES CO., LTD.

China

Air Dielectric cable used as feeder cable for broadcast transmitting system.

Request for a quote

TECHNIC MACHINES

Turkey

We design our coil feeder machine for working precision feeding and without damage on sheet metal surface. Our coil feeder machines provide to have working possibility with high speed and precision sheet metal feeding results during press feeding. We have as alternative for coil feeder machine standard models. And we design and provide for different request specific coil feeder machines. We supply our coil feeder machines as to our customer's requests and needs, according the working sheet raw material, thickness and width. We check our customer’s final target product and requested production capacity, then we offer the optimum solution coil feeder machine solution.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOSPORAS

Turkey

Our 11-roller ACZ series compact servo feeder lines which have 600 and 1600 mm of coil width, between 2 and 10 mm thickness and 15.000 kilograms capacity is used as a compact press feeding machine. Our compact system servo feeder machines can process different kinds of materials like aluminum and other soft alloys, hot or cold foliated materials, carbon and stainless steel, high integrity materials and lamination steel. 11-Roller Compact Coil Servo Feeder System Components Hydraulic Decoiler Hydraulic Coil Car Hydraulic Inner Tightening and Unloading Automatic Coil Centering Feature Snubber and Upper Arm Coil Guidance Platform and Peeler Feature

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Busbars are typically used in high current, low voltage distribution and control equipment. Typical busbar applications include busway systems, low and medium voltage switchgear, transformers, earthing, electrification - lines panel boards, switchboards, and feeds to heavy electrical uses in commercial and industrial buildings - such as plating cells and feeder systems. Busbars can be made from copper or aluminum, but we couldn’ t argue the reality that copper bus bars are the better electrical conductors. Also installers can use smaller busbars if they are made by copper. On the other hand copper busbars have better resistance to corrosion than the aluminum busbars.We have large production facilities for extruded and drawn flats in various production range of sizes and shapes for electrical engineering, anodes, components etc.

Request for a quote

BOSPORAS

Turkey

Our 11-roller ACS Series compact system press feeding machines consist of 600 and 1600 coil width, 2 and 10 mm of sheet metal thickness, between 6.000 and 15.000 kilograms of coil weight capacity feeder, straightener and decoiler. 11-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

Our 7-roller ACS Series compact system press feeding machines consist of 60 and 1300 coil width, 0,5 and 4 mm of sheet metal thickness, between 6.000 and 10.000 kilograms of coil weight capacity feeder, straightener and decoiler. 7-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

Our 7-roller ACS Series compact system press feeding machines consist of 60 and 1300 coil width, 0,5 and 4 mm of sheet metal thickness, between 6.000 and 10.000 kilograms of coil weight capacity feeder, straightener and decoiler. 7-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Busbars are typically used in high current, low voltage distribution and control equipment. Typical busbar applications include busway systems, low and medium voltage switchgear, transformers, earthing, electrification - lines panel boards, switchboards, and feeds to heavy electrical uses in commercial and industrial buildings - such as plating cells and feeder systems. Busbars can be made from copper, but we couldn’ t argue the reality that copper bus bars are the better electrical conductors. Also installers can use smaller busbars if they are made by copper. On the other hand copper busbars have better resistance to corrosion than the aluminum busbars.We have large production facilities for extruded and drawn flats in various production range of sizes and shapes for electrical engineering, anodes, components etc. They are produced OF upward cansting than Contunious processing and drawing.

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Busbars are typically used in high current, low voltage distribution and control equipment. Typical busbar applications include busway systems, low and medium voltage switchgear, transformers, earthing, electrification - lines panel boards, switchboards, and feeds to heavy electrical uses in commercial and industrial buildings - such as plating cells and feeder systems. Busbars can be made from copper or aluminum, but we couldn’ t argue the reality that copper bus bars are the better electrical conductors. Also installers can use smaller busbars if they are made by copper. On the other hand copper busbars have better resistance to corrosion than the aluminum busbars.We have large production facilities for extruded and drawn flats in various production range of sizes and shapes for electrical engineering, anodes, components etc.

Request for a quote

BOSPORAS

Turkey

Our 11-roller servo feeders work between 300 and 1.600 millimeters of width and, 1 and 8 millimeters of thickness. Our straightener servo machines’ full-auto piloting system works with feeder and straightener rollers. Our company mass produces 11-roller Model with static body and in accordance with Conformité Européenne (CE) Regulations.

Request for a quote

BOSPORAS

Turkey

Our 7-roller straightener servo feeders work between 300 and 1.600 millimeters of width and, 0,5 and 5 millimeters of thickness. Our straightener servo machines’ full-auto piloting system works with feeder and straightener rollers. Our company mass produces 7-roller Model with static body and in accordance with Conformité Européenne (CE) Regulations.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

The GBOX-802CD is a weighing module developed for linear feeder packing systems with vibrators. The new algorithm makes the weighing control faster and more accurate. Various communication ports make the equipment easier to interconnect with the system. It is suitable for weighing powdery or small granular materials in sizes from 10.0 to 5000.0 g, such as sugar, salt, seeds, rice, sesame, spice, milk powder, coffee, washing powder, etc.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with servo auger/agitator feeder system,30-50L fillers,and lifting conveyor,accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design ,compact and reasonable arranged in the smallest amount of space,to automatic control of a series of processes from bag-giving,coding,bag-opening,filling, sealing, and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials. 3.Adopt Siemens PLC control system, touch screen can set variety of languages,simple operation, and easy maintenance. 4.The machine use premade pouch,you have more choice for the bag type and excellent appearance .Sealing good, the finished product looks high-end. 5.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 6.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

ALPHA LASER GMBH

Germany

The laser welding systems of the AL series can be used universally. They might be integrated into existing machine structures or used with an application device for manual welding. In combination with our NC-controlled laser machining table AL-T you get a real professional solution. We offer the required performance class for every application. You can choose between 75 and 900 W. There is a wide range of processing lenses and equipment options for these laser systems. Regardless of whether you use a simple 90 ° deflection lens, the tilt-swivel lens or our circular welding lens - the laser beam always reaches the desired point on the workpiece with pinpoint accuracy. Additional equipment options are optionally available for the AL, such as: • Micro welding device for a welding spot diameter <100 µm • Rotary axis module for cylindrical welds • automatic wire feeder • Workpiece holder • camera system •…and much more

Request for a quoteResults for

Feeder system - Import exportNumber of results

50 ProductsCategory

- Cutting - machine tools (6)

- Food industry - machinery and equipment (5)

- Copper and copper alloys (3)

- Copper wires and cables (3)

- Mechanical surface treatment - machinery (3)

- Metal straightening machines (3)

- Automation - systems and equipment (2)

- Finishing and binding - machinery and equipment (2)

- Laser - cutting and welding machines (2)

- Wood veneer - machinery and equipment (2)

- Bottling and filling - machinery and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Chemical industry - machinery and equipment (1)

- Custom packaging (1)

- Engineering - industrial consultants (1)

- Flour-milling (1)

- Goods handling systems, continuous (1)

- Machine vision system (1)

- Mechanical engineering - custom work (1)

- Mechanical transmission - components (1)