- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- feed tanks

Results for

Feed tanks - Import export

ELKON GMBH

Germany

Cement material supplied with big bags or bags can be transferred into cement silos by means of ELKON Big Bag/Bag Pneumatic Cement Feeding System. ELKON Big Bag/Bag Pneumatic Cement Feeding System consists of cement feeding hopper, intermediary feeding screw, pressure tank, compressor, loading crane and control panel. This feeding system, which has a capacity of 15 tons/hour, is equipped with 2 tons crane to lift the big bags and dispatch into the feeding hopper. The complete set of ELKON Big Bag/Bag Pneumatic Cement Feeding System fits into 1 unit 40’OT container and thus it can be easily transported to overseas countries.

Request for a quote

ELKON GMBH

Germany

In some countries, cement is widely delivered by railway. The cement carried in wagons can be transferred to the cement silos with special pneumatic cement feeding system developed by ELKON. ELKON Cement Delivery System from Railway consists of wagon feeding hopper, intermediary feeding screw, material holding tank, pressure tank, compressor and control panel. The system which has a cement feeding capacity of 50 tons / hour can also be used to feed a large number of cement silos.

Request for a quote

A.B.S. SILO- UND FÖRDERANLAGEN GMBH

Germany

Flexible indoor silo made of breathable, uncoated polyester fabric for a constant feed quality without the formation of mould and lumps. The lowest-cost storage possibility with an optimal space utilisation.

Request for a quote

A.B.S. SILO- UND FÖRDERANLAGEN GMBH

Germany

Flexible indoor silo made of breathable, uncoated polyester fabric for a constant feed quality without the formation of mould and lumps. The lowest-cost storage possibility with an optimal space utilisation.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Water treatment for steam boiler systems — Prevention of corrosion in the boiler — Outstanding deaeration efficiency and reduced consumption of chemicals with WSM-V complete deaeration system — Partial deaeration module WSM-T for small systems — Fast and easy planning, installation and acceptance appropriate to the steam boiler in question — Requirement for positive suction head allows for ground-level installation and easy commissioning

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

With the new EMX model range of electric steam boilers, CERTUSS offers you twice the steam output as before with a significantly smaller footprint. Electric steam generators from CERTUSS are heated by stainless steel heating rods with a large heating surface. The output of the heating elements is regulated continuously via semiconductor contactors. One energy-efficient advantage is the immediate modulating output adjustment to the actual steam demand during the operating cycle. For greater steam demand of up to 640 kg/h or fluctuating steam loads, several ELECTRO steam generators can be cascaded in series. Multiple systems like this are an especially economical solution. Our compact electric steam systems feature built-in feed water tanks and feed water pumps. They require very little space and have a short heat-up time. Steam systems are also available as a unit with water conditioning equipment installed at the factory.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

Our steam generators are available on request as a ready-to-operate steam boiler plant: CERTUSS steam generator plus CERTUSS supply unit CVE. All components for the water supply and water conditioning of the CERTUSS steam generator are included in the complete steam plant. - Feed water tank - Desalination heat exchanger - Water softening equipment - Test extraction cooler - Mixing heat exchanger - Measuring equipment - Steam dryer The CVE supply unit is compatible with all the CERTUSS steam generators. In addition to the CERTUSS supply unit as a ready-to-operate boiler house installation on a basic frame, we also offer a complete container installation on request. Depending on the desired steam output a multiple steam boiler plant may be suitable for you.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

Marking system for double-sided offset printing of cable insulation with synchronized, phase-adjustable printing wheels Double-sided indirect gravure printing Indirect printing system Marking speeds up to 100 m / minute Marking cold plastic tubing and hoses as well as plastic insulated cables including products with irregular surfaces STANDARD CONFIGURATION Marking unit with two marking stations. Complete marking station with ink tank, solvent feed unit, printing disc shaft, and rubber faced transfer roll. 1 set jof dedicated ink wipers and guide roller matching the specified printing disc. Complete accessories kit without printing discs.Offset printing machine using laser engraved printing discs and rubber faced transfer rolls. Transfer rolls synchronized and phase-adjustable during operation for ring marking or spiral striping. Easy to set up and operate. Printing discs and transfer rolls driven by product being marked. Available on request with auxiliary drive for marking

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

General-purpose offset printing system for cold plastic tubing and hoses as well as plastic insulated cables including products with irregular surfaces. General pupose printer Indirect printing system Marking speeds up to 150 m / minute Marking cold plastic tubing and hoses as well as plastic insulated cables including products with irregular surfaces STANDARD CONFIGURATION Frame with support column and height adjustment crank mechanism. Marking unit with one marking station, guide rollers, and drive wheel. Complete marking station with ink tank, solvent feed unit, printing disc shaft, and rubber faced transfer roll. 1 set jof dedicated ink wipers and guide roller matching the specified printing disc. Complete accessories kit without printing discs.Offset printing machine with laser engraved steel printing disc and rubber faced transfer roll Also suited for flexo printing using rubber plates (available separately)

Request for a quote

DINO ANLAGE- UND MASCHINENBAU E.K.

Germany

Fully equipped steam boiler with feed water tank

DINO ANLAGE- UND MASCHINENBAU E.K.

Germany

We supply units up to 750kg/h! Complete with feed water tank, pumps and controls

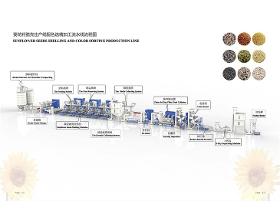

YONGMING MACHINERY MANUFACTURING CO., LTD

China

It involves a great deal of preparation to have a beautifully decorated design. We start with measuring the workshop area to get its length, width and height, then according to the entrance or exit of workshop, we are to plan the starter in the processing line. That includes how the materials are to be fed, pit making or feeding platform, and storage tank for materials reserving or processing directly. We need to consider how many materials would you be processing? And what is the degree of quality that you need? Where is the proper place for storage finished products? Where is the good exit for finished products transportation by truck? When all these information are gathered then we will be contributing to processing equipment.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

With view of the increasing market demand for sunflower kernel oil, basing on 20-year patented dehulling equipments’ manufacturing advantage,the large capacity sunflower seed dehulling equipment for oil pressing purpose KTF5-3000 is our self-developed equipment to meet the needs of large capacity with premium quality of sunflower kernel oil production. Fully Equipped Seed Processing Production Line Plant . It involves a great deal of preparation to have a beautifully decorated design. We start with measuring the workshop area to get its length, width and height, then according to the entrance or exit of workshop, we are to plan the starter in the processing line. That includes how the materials are to be fed, pit making or feeding platform, and storage tank for materials reserving or processing directly. We need to consider how many materials would you be processing? And what is the degree of quality that you need

Request for a quote

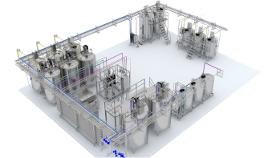

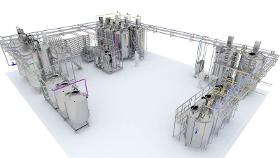

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple product viscosity and types Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

SPECIFICATION Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

1,Specification •,Milk Double jackets cooling collecting tanks •,Chillers. •,Storage feeding tank •,Processing section •,Cheese press to mold machines •,Mozzarella cheese making machines •,Vacuum cooker cream cheese making machines •,Rotary bottles washing system •,Milk, yogurt and cheese filling, sealing and capping machines •,Fermentation room. •,Compact design •,Available certification up on your request UL, CE, GMP, FDA, ASME. •,Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. 2,Description ,High stability on high capacity. ,Can handle multiple ointment viscosity and types ,Type of metal used S.S 316 / 304 ,Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018

Request for a quote

FILTRATION SERVICES LTD

United Kingdom

The Rotavac Lab is a fully functional and representative lab scale rotary drum vacuum filter (RDVF) and filtration system, generally used for product evaluation tests or as a preliminary step towards pilot scale and full scale equipment trials. The unit can be used to validate the suitability of this type of continuous vacuum filtration equipment. The equipment offers the advantage of an easily interchangeable discharge system so that different configurations can be trialled if required. It is supplied with a control panel for modifying drum and agitator speeds and, when using a precoat discharge, the knife advance rate. A separate skid mounted feed tank, mixer and feed pump is included with the RDVF. The unit is easy to assemble and we can provide full detailed instructions including photographs at the point of hire. We include filter cloths from our extensive range of fabrics. Please contact us for more information if you are interested in purchase or hire of this lab filter.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PERO AG

Germany

After production of repair, the workpieces are lowered in a parts carrier into the immersion tank. A pump feeds cold cleaning agent containing solvents into the tank so that dirt is dissolved and removed by flooding. Persistent dirt can be removed manually with the flowthrough brush. The cleaning medium in the tank is constantly recirculated through a filter. Cleaning with sprayable cold cleaning agents containing hydrocarbons with a flash point > 60 °C Manual cleaning station Continuous filtration of cleaning medium Immersion tank suitable for wide range of workpieces Available as 1bath unit with loading of the unit via Manual loading

Request for a quote

ADVANCE APPLIANCES

United Kingdom

Use these Advance Thermal Stores for the provision of fast, safe hot water provision throughout the house. The indirect pattern cylinder (TSiC) without the integrated feed and expansion tank has to be fed with a remote F and E tank but can be sited anywhere in the property. They have two coils, the lower one for heat input from a boiler, the higher one for mains fed hot water services. They can be used with sealed system boilers and heating circuits on Y plan systems. These low maintenance pre plumbed units provide flow rates up to 30 litres per minute and if linked to the appropriate gas, oil, or LPG boiler are suitable for average to larger properties. The bottom coil must be pumped. The units look smart too, with a wipe-clean white appliance finish, and the insulation is 60mm foam injected for maximum efficiencies. Stainless steel construction offers a lightweight long life product. The stores are guaranteed for ten years, the parts for two.

Request for a quote

ADVANCE APPLIANCES

United Kingdom

Use these Advance Thermal Stores for the provision of fast, safe hot water provision throughout the house. The indirect pattern (TSi) Twin Coil with the integrated feed and expansion tank can be sited anywhere in the property. The lower coil can be connected to a sealed system boiler in a Y plan, thus only one pump is needed. The store remains vented, with the contents of the store used as a medium for heat transfer only. These low maintenance pre plumbed units provide flow rates up to 30 litres per minute and if linked to the appropriate gas, oil, solid fuel, biomass or other appliance (except Heat Pumps) are suitable for average to larger properties.

Request for a quote

ADVANCE APPLIANCES

United Kingdom

Use these Advance Thermal Stores for the provision of fast, safe hot water provision throughout the house. They work on the thermal store principle of storing central heating water and providing mains fed hot water via a powerful coil for power showering and quick bath filling. The coil is not pumped. The thermal store acts as a buffer for fast radiator heat up and boiler efficiency. The direct pattern cylinder (TSDC) without the integrated feed and expansion tank has to be fed with a remote F and E tank sited above the highest point of the radiator circuit. You need two pumps - one for the boiler to keep the store hot - controlled by the thermostat on the store, and one for the heating circuit - controlled by the room thermostat and heating programmer. These low maintenance pre plumbed units provide flow rates up to 30 litres per minute and if linked to the appropriate gas, oil, solid fuel or biomass(except Heat Pumps) are suitable for average to larger properties

Request for a quote

ADVANCE APPLIANCES

United Kingdom

Use these Advance Thermal Stores for the provision of fast, safe hot water provision throughout the house. The thermal store principle stores central heating water in the tank. Mains pressure hot water is created with an internal powerful coil for power showers and quick bath filling. This coil is not pumped. The thermal store acts as a buffer to reduce boiler cycling and improve efficiencies - and heats the radiators quickly. The direct pattern (TSD) single coil with integrated feed and expansion tank has to be above the radiator circuit as the water is drawn from the tank for fast heat-up. You need two pumps - one for the boiler to keep the store hot - controlled by the thermostat on the store, and one for the heating circuit - controlled by the room thermostat and heating programmer.

Request for a quote

THE FILTER PRESS COMPANY LTD

United Kingdom

This Filter Press installation has a 2,500 ltr Feed tank with agitator, a 3m3 / hr Mono-Pump to feed the Press. There is a 10 bar pressure transducer in the feed line to tell out PLC control panel that the press is full and to start the Automatic Emptying of the Filter Press.

Results for

Feed tanks - Import exportNumber of results

24 ProductsCountries

Company type

Category

- Water-heaters, domestic (4)

- Agricultural systems and equipment (2)

- Boilerwork (2)

- Concrete mixers (2)

- Fabric printing - machinery and equipment (2)

- Food canning and preserving - machinery and equipment (2)

- Food industry - machinery and equipment (2)

- Silos, farm (2)

- Water retreatment - equipment and installations (2)

- Cleaning machines, industrial (1)

- Dairies - machinery and equipment (1)

- Laboratory equipment and instruments (1)