- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- feed machine

Results for

Feed machine - Import export

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to feed regularly the granular or powdery product into a conveying line or a machine at a suitable rate especially at flour mills

Request for a quote

ROBINSON CO.

Turkey

The wing formation inside the machine feeds the product at a stable rate to the transport line. The accurate tolerance between the body and the wings prevents the pressurized air to reach the product inlet. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

The Air Channel is used for cleaning wheat, barley, legumes and soybeans. The machine removes all kinds of light materials different from cereal grains in terms of aerodynamic properties: garbage, straw and spike fractures, various seeds, peeled shell and dust from the product by means of air flow. While the grain products are distributed homogeneously in the width of the Air Channel with the feeding table of the machine or a vibrating feeder, the light particles in it are conveyed to the upper outlet channel with the air flow coming from the bottom, and the cleaned product falls down and transferred into the system. ◾ The lighting created by the window enables the separation to be seen clearly and thus all kinds of air adjustments can be made. ◾ Manufactured in two types, this machine with vibro motor is usually used with a Peeler machine, the non-motorized one is used with a Garbage Purifier machine.

Request for a quote

PARSMEGA MAKINA

Turkey

Garbage separator machine is used to separate foreign grain products such as garbage and straw in wheat. The garbage purifier consists of two parts. Upper sieve part: It separates the large foreign substances in the wheat and throws them out. Lower sieve part: It eliminates small foreign substances from the wheat that pass through the upper sieve part and fall on it. Both screen wires can be easily removed and installed by hand. Wheat entering the machine from the product entrance is distributed smoothly and homogeneously on the sieve thanks to the vibromotor mounted on the center of gravity of the machine. The feeding box is oscillated with the body working by vibration on rubber wedges. With an adjustable flap, it ensures that the wheat is distributed across the entire sieve surface.

Request for a quote

ROLLON GMBH

Germany

Versatile multi-axis system designed for feeding machine stations. The Y axis can be realized with a rack and pinion driving system for multiple independent carriages or with a short belt system for connected Z axes. The motion systems can be designed with recirculating ball guides or with bearings depending on loads, dynamics, and different environments. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. The wall-mounted system feeds the machine and retracts, facilitating the feeding of machine tools where obstructions to protective doors must be avoided. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Jung JF520 surface and profile grinding machine in very good condition. Machine No. 1569. Year of construction 1981 - Grinding length max. 600 mm - Sliding width: 200mm - Magnet size: 500x175mm - Grinding wheel dimensions: 250x25x50.8mm Bcspaqsayd8 - Spindle speed: stepless 4200 omw./min. - 380V 4kW - Weight about 2000kg Equipment: - 1 axis digital display, - Flanges - Infinitely adjustable spindle speed - Infinitely variable hydraulic supply in transverse direction - auto lubrication system, - Automatic height feed with rapid traverse - machine books

Request for a quote

MICRON AMERICA

Turkey

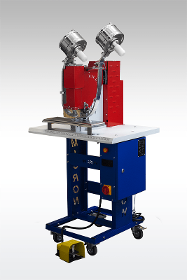

Micron M-500 fully automatic, eyelet and washer attaching machine. This machine is built around a newly designed frame that requires less space and is much lighter than previous generations of machines. The M-500 fully automatic machine that feeds both the eyelet and washer punches the hole in the material and attaches the eyelet and washer, all in a single cycle. This machine has been specifically engineered for light to medium duty applications.

Request for a quote

MICRON AMERICA

Turkey

Fully automatic, self loading machine. Fed by hoppers. Punches a hole and sets the grommet in one step. Can only accommodate one size die for the lifetime of the machine. Foot pedal for hand safety. Requires 220 volts of AC power to operate. This machine is built around a newly designed frame that requires less space and is much lighter than previous generations. The M 500 fully automatic machine that feeds both the grommet and washer punches the hole in the material and attaches the grommet and washer, all in a single cycle. This machine has been specifically engineered for light to medium duty applications. Features Flywheel powered and cam actuated to ensure consistent settings. Advanced cutting technology to punch a hole in multi layeredmaterialsCompensator to allow for a nominal variance in material thickness.Stripper plate to lift grommet and washer setting off the pilot ofthe anvil.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This coin feeder enables continuous feeding of a coin sorting machine or a coin wrapping machine. Fill level controlled by detectors. Adaptation to your coin trolleys. - Robust frame made of epoxy painted steel - Hooking device for all types of trolleys - Specially designed trolley that is easily handled and adaptable to the forklift truck - Possibility of manufacturing to your dimensions depending on the quantity required - Height adjustable from 500 to 1300 mm - Dimensions can be changed on request - Speed: up to 7000 pieces/min - Speed control by variator The materials comply with the applicable EC standards.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Felt roller lubricators For evenly dosed application Targeted lubrication of metal coils and blanks We offer felt roller lubricators in a variety of different model ranges. The rollers are generally driven by the feed machine, but we also offer systems equipped with their own transport units. Features & benefits • Versions with their own transport unit • Rollers easily and quickly changed • Rugged, wear-resistant workmanship • Numerous application options for coil gauges from 0.5 to 10 mm • Viscosities up to 150 mm2/sec possible Design versions and details In this field we offer three product lines with different roller diameters. 32 Series Our compact felt roller lubricators are designed for coil gauges up to 0.5 mm as well as viscosities up to 100 mm2/sec (recommended guideline values). Fields of application Contact components: tab connectors, electric switching contacts, contact springs Punched and bent parts: medical technology, microelectronics, precision engineering Fine bla

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

This machine is used for plastic round, shaped or square bottles unscrambling equipment. No matter what the status of the bottle feeding, the machine can automatically complete the bottle feeding, bottle unscrambling, flip, arranging, bottle output, and connected with later packaging equipment. The machine uses high quality stainless steel or non-toxic pollution-free engineering plastic, adopts mechanical transmission technology, different bottles can work on a machine by adjusting machine parts, has stepless adjustable speed, simple operation, high degree of automation.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The predominant use of LAWECO lifting platforms in the paper industry is for the formation and separation of stacks. Additional application possibilities are the handling of paper rolls and rack loading. Movable lifting table to feed a printing machine with foil material. Dimension: 1700 x 840 mm Operating stroke: 700 mmm Rated load: 2500 kg

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

A flexible and cost-effective way of connecting tubes to each other reliably and stably. RK Rose+Krieger developed the precision-cast stainless steel tube connectors specially for heavy loads and impact-resistance. The high-strength tube connectors are resistant to high temperatures and corrosion, and are engineered for dynamic loads. An electrochemical passivation – the tube connectors are electropolished in a final working step – makes them more resilient and resistant to acids than elements made of untreated stainless steel. As a result they are particularly resistant to cleaning with aggressive cleaning agents or hot water from high-pressure cleaners, and ideally suitable for use in packaging machines or for feeding technology in plants in the chemicals industry. Stainless steel clamp connectors are tough. Stainless steel clamps are particularly important for users working in the fields of chemical and food technology.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

This fully automatic sleeve labeling machine is suitable for various kinds of bottles,like round bottles, square bottles,oval bottles,etc.This machine can automatically feed and cut film,and it can sleeve labels precisely,greatly saving labor and improving work efficiency.The machine can be widely used for beverage bottles,cosmetic bottles,shampoo bottles,etc. The touch screen control panel makes the working parameter is visual,the precise adjustment can be easily achieved according to operation Equipped with high quality electric eye,It can pull film automatically,it is more convenient and easier to operate the machine. The bottle separating component can help to separate bottle and adjust bottles distance,ensure the bottle can be labeled in order,improve the labeling effect. Rotary knobs are designed for adjusting the position of different mechanisms, make sure the machine can sleeve label precisely.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-OF Automatic Multy Head Overflow Liquid Filling Machine works by feeding the liquid through a specific pump or a top storage tank. Simultaneously, once the feeding is completed, a portion of the material returns to the liquid overflow tank via the overflow port to guarantee the filled bottle in same level. The depth of the overflow port in the container neck determines the container’s filling level, which is easily adjustable. The number of filling heads can be increased to meet production needs. It’s ideal for filling low-viscosity, high foamy liquid in the chemical, food, pharmaceutical, and other sectors. Vacuum overflow filler system is for optional,filling nozzles moving up and down by servo motor driving, specially designed overflow filling nozzles.

Request for a quote

FERPLAST SNC

Italy

Electric sewing machine for sacks model FPGK 350. This model is recommended for production up to 450 sacks per day. New model of the FPGK series designed for the seam of juta, paper, fabric, plastic and net bags. The front part of the stapler is made of metal while the handle is made of plastic. Given its features this electric sewing machine is suitable for farms, warehouses, post offices and food and chemical industries. It is a good solution for the closure of bags of any material and dimension due to the automatic feed. This light and handy machine is the fastest in its class. The standard model must be connected to the electric current of 220V. The maximum span passage is 10 mm. The material you can sew, if different from those listed must be low density (to avoid breaking of the needles).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WEBER ULTRASONICS AG

Germany

Utilize Weber Ultrasonics technology for your system just like your application demands it. The innovative and highly modular Saphir machine concept is a breeze to integrate in existing process lines and can be customized to individual requirements. The machine components generator, feed unit, swing unit and Touch-PC with the powerful control software SAPHIR CONTROL 4.0 and extensive accessories are pre-configured and ready for use.

Request for a quote

FERPLAST SNC

Italy

The ME-FD double Impulse sealers with pedestal incorporate twin elements (top and bottom) for heavy-duty applications and can accommodate up to 0.5mm material. Makes a 5 mm wide seal and fuses the material from both sides. Ideal for sealing large heavy bags. Also equipped with slide switch to select single side sealing or double sides sealing. By having a foot control, the hands are free to feed the machine. Units come complete with pedestal, stand, adjustable working plan and adjustable foot control. The sealing time is adjustable with a timer and is indicated by a light. Easy and simple to operate. No pre-heating required. Maximum seal thickness 0,25 mm. (0,50 mm total).

Request for a quote

FERPLAST SNC

Italy

MINI TWIST 140-160 CABLE - SEALING MACHINES WITH TWIST BAND Twisting manual machine, designed and built to tie different kinds of product, with a twistband wire. It is mode in varnished steel assuring a long life. The MINI TWIST is user-friendly and astonishes for its simplicity. It makes possible a grow of productivity of the worker himself. The machine is feeded by a reel of plastic wire, so-called "Twist band" which has a metal wire inside.

Request for a quote

BIZERBA SE & CO. KG

Germany

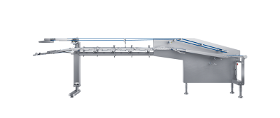

Optimizes package handling in material flow systems By channeling up to 6 product lanes into a single line the LCE allows controlled product feeding from the packaging machine to the price labeler. Due to specially formed and Teflon-coated alignment rails the converger belt proves its effectiveness especially for flat packages. It can be infinitely adjusted from 10 - 80 m/minute and individually set for each PLU.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The CompactLoader is an especially compact infeeder which transports sliced portions fully automatically and feeds them into a packaging machine – all at a very modest footprint. Human touch of groceries is practically reduced to zero. Cleaning times of the CompactLoader are short and efficient. Advantages Compact, small footprint Modular adjustable system Weber hygienic design Arranges portions in die fomats, buffers them and places them in the packaging machine One design in different configurations – from base to top Space saving due to integrated rocker Optimal access to packaging machine by raising the buffer conveyors Infeeding belt foldable and swivable side-wise Easy cleaning, maintenance and service Options: Upper reject conveyor Buffer conveyor (2, 3, 4) Grouping conveyor (3, 4) Line divider – 2 axis 1 > n or 2 > 2 n Line divider – 3 axis 1 > n, 2 > 2 n, 2 > 3

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to its high resolution also when measuring long distances, linear displacement measurements up to 900 mm can be carried out. Conversions between rotatory and translation movements through ball screws, wire or cord connections and so on are not necessary for direct displacement measurement. Application fields include: —Electromagnets —Deformations - bending —Pneumatic cylinders —Length tolerances —Press-insertions (longitudinal press-fits) —Feed strokes —Machine hubs —Punch, knee lever or extruder distances —Hydraulic cylinders Due to the technology employed in potentiometric displacement sensors, they always operate with a sliding contact system. Special processes are applied to give the resistance tracks low friction, low tendency to stick/slip, resistance to abrasion and long-term stability. The rod is guided in a low-play floating frontal bearing. This absorbs small angular and parallel displacements.

Request for a quote

SPIROL

Germany

SPIROL is a technical resource that provides high quality components that improve the quality of your assembly, extend the life of your products and reduce your manufacturing costs. We are the leading global manufacturer of engineered fasteners, shims, installation machines, and parts feeding equipment producing over two billion components annually. In addition to high quality products, SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and global stocking facilities to simplify the logistics of delivering your product. If you have any questions or would like complimentary Application Engineering support, please feel free to contact us at any time!

Request for a quote

SPIROL

Germany

Some of SPIROL's standard Pin Installation Models can be equipped with a pusher punch (in place of a pin insertion quill) to press Threaded Inserts into plastic assemblies. The most appropriate Installation Machine depends on the actual insertion force required to press the Insert into the plastic hole and the desired productivity. Generally speaking, the Model PMH Heavy Duty Installation Machine is typically used for low to medium volume installation, and for medium to high volume installation, SPIROL's Model PH/PHX Platen-Style Installation Machines can be used for simultaneous installation of several Press-In Inserts at the same or different elevations. Due to the length to diameter ratio of Press -In Inserts, it is not possible to cost-effectively tube feed this type of Threaded Insert with SPIROL's automatic feeding and Installation machines.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit centerless grinding wheels can grind workpieces from a few millimeters to several meters in length with maximum precision and cost-effectiveness, ideal for large series of identical parts. Centerless grinding wheels are notably thick compared to their diameter. Special pressing processes, adapted specifications, and sometimes split grinding wheels ensure homogeneous density distribution. Tyrolit offers a complete assortment of grinding wheels, regulating wheels, and dressing tools. Continuous product development guarantees high stock removal, tight tolerances, and fine surface results. Resin-bonded CBN grinding tools with a fiber-reinforced composite carrier body offer up to 80 percent less weight and better absorption properties, enhancing grinding results and tool life. Vitrified-bonded wheels use innovative sintering technology to prevent abrasive grain breakage. Lightweight diamond wheels are available for centerless through-feed grinding, gentle on machine spindles.

Request for a quote

FERPLAST SNC

Italy

CF SERIES - CONSTANT TEMPERATURE HEAT SEALERS WITH PEDESTAL AND FOOT PEDAL ( for multi-layer bags) THE CF SERIES of constant heat sealers with pedestal and operated by foot pedal, are ideal for sealing bags made of compunds, multi-layer films, co-extruded films, OPP, heat-sealable cellophane. It is not suitable for polyethylene films. Being operated by foot pedal, the hands are free to feed the machine. The sealing jaws of the type "hot bar" are equipped with resistance and temperature controller for controlling the temperature from 30 ° C to 200 ° C. The temperature of the sealing jaws is adjustable according to the type and thickness of the material to be sealed, and is kept constant by a heat thermo-regulator. The maximum sealable thickness, that always varies according to the type of sealable material, is 0.25 mm. (50 mm. total). Also available in CFN version with timer and acoustic signal at the end of sealing.

Request for a quote

DAMS MACHINE

Turkey

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use. Optionally, it is produced so that a coding device can be mounted on the machine. Cellophane bobbin is easy to disassemble and install, the place where it is mounted is an air system and PLC controlled shaft.

Request for a quote

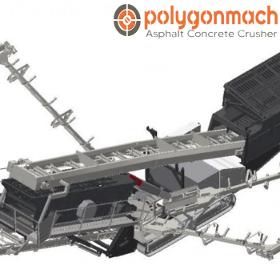

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A track-mounted impact crusher is a mobile crushing unit that is mounted on a set of tracks to move along even the most serviceable areas with efficiency. Unlike the traditional stationary crushers, these machines can easily be relocated at any location within a work site for better adaptability with the ever-changing demands of a project. The "impact" mechanism designates the working principle of the crusher, whereby the material is brought into the crushing chamber and receives repeated impacts from the rotor, thus being reduced in size. The track-mounted impact crushing machines have automated feeding systems, setting modifications according to various material types, and added abilities for better mobility. This mainly allows these machines to perform at large-scale projects involved in mining, road building, and demolition. Models from Polygonmach boast innovations that ensure each unit performs well in terms of crushing, whatever the nature or topography of the material.

Request for a quoteResults for

Feed machine - Import exportNumber of results

131 ProductsCountries

Category

- Food Industry - Machines & Equipment (6)

- Adjustment - machine tools (4)

- Cutting - machine tools (4)

- Industrial cutting machine tools (4)

- Troughs and feeders (4)

- Axles, vehicle (3)

- Conveyor systems (3)

- Crushing and grinding machinery (3)

- Milling - steels and metals (3)

- Packing and packaging - machinery and equipment (3)

- Plastics - industrial machinery and equipment (3)

- Printer paper (3)

- Conveyor belts (2)

- Flour milling - machinery and equipment (2)

- Grinding - machine tools (2)

- Internal transport systems (2)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (2)

- Metal straightening machines (2)

- Mining and quarrying - machinery and equipment (2)

- Package sealing machinery (2)