- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- extrusion of plastic materials

Results for

Extrusion of plastic materials - Import export

SPN SOCIÉTÉ DES PLASTIQUES NOBLES

France

Adapted to very low temperatures (cryogenics), our plastics allow sealing with very good mechanical performances even with temperatures that can reach -196°C : PCTFE is also called PTFCE, Voltalef ®, KEL-F ®, Neoflon ®

Request for a quote

LOUISON INDUSTRIES

France

Discover coextruded tape, used in the building and public works and agriculture sectors as reinforcement in a construction operation (e.g. reinforced earth, tutoring...). A combination of textile and plastic, coextrusion is a process that involves melting thermoplastic resins which then cover the textile in the form of threads (high-tenacity polyester threads, for example). Each material brings its own properties to the product. So, according to the specifications we receive, we will incorporate all the characteristics you need: resistance, texture, etc... Note: the plastic residues generated can be transformed into reusable beads, reducing the overall waste produced during the extrusion process.

Request for a quote

STAMIXCO AG

Switzerland

The GX static mixer has been used successfully for the laminar flow mixing and/or dispersion of viscous fluids for over 35 years. It is a high performance static mixer capable of mixing materials with equal or very large differences in viscosity and volumetric ratio. Mixing is accomplished in a short length with a very high degree of mixing. Mixing Capabilities Mix fluids with similar viscosity Mix fluids with high and low viscosity (1 million : 1) Mix fluids with large differences in volumetric ratio (1,000 : 1) Disperse and mix polymers with blowing agents Thermal homogenization Viscosity homogenization Applications Polymer manufacture and processing. Two (2) component viscous materials such as Liquid Silicone Rubber (LSR), adhesives, polysulfide, sealants, epoxy resins, polyurethanes, etc. Plastics Extrusion Materials of Construction, Housings and End-Connections The GX static mixer can be supplied in most materials of construction, pipe/tube housings with virtually any end connection (Figure #13). GX-P mixing elements in 9.3 - 9.4mm outside diameter size are also available in plastic construction. History of GX Static Mixing Structure The GX static mixer was invented by Bayer AG of Leverkusen, Germany in the mid 1970’s. Bayer used the GX static mixer extensively in their polymer plants and subsequently licensed the design to Sulzer Chemtech of Winterthur, Switzerland who trademarked the design as the SMX* static mixer. Sulzer did a tremendous amount of fundamental high quality R&D work on the SMX structure and commercialized the SMX static mixer in tens-of-thousands of successful installations. The founders of StaMixCo held key technical and management positions in the Koch Engineering (the later Koch-Glitsch)-Sulzer Chemtech team that commercialized the SMX static mixer. Bayer licensed their 2nd generation of the SMX static mixer to StaMixCo which is branded as the GXR structure with integral support ring around the X-Grid mixing bars as described in a previous section of this web site. * StaMixCo is not a distributor of or affiliated with Sulzer Chemtech. SMX is a brand and trademark of Sulzer Chemtech.

Request for a quote

PLASTICOS ESCANERO S.L

Spain

We manufacture our cores in all plastic materials, also recycled ones. We lead recycled PVC market in Europe, as we are certified recyclers Consult us without commitment!

Request for a quote

W. MÜLLER GMBH

Germany

Space-saving in a vertical (e.g. for retrofitting) but also in a horizontal version, our extruders are available in many variations for your specific needs. For applications with larger throughputs, we have high-quality extruders with heat-separated feed zone cooling, which deliver a high-quality melt for the further process. We also offer coordinated screw designs for special materials such as PVC, PA, EVOH, E-PET or adhesive layers.

Request for a quote

SAMPACKT AMBALAJ SANAYI VE TICARET LIMITED SIRKETI

Turkey

Low-Density Polyethylene (LDPE) that has been recycled and processed to create a GREY material. This material maintains the durability and flexibility of standard LDPE while promoting sustainability by utilizing post-consumer recycled content. It is certified by EUROCERT and meets PCR (Post Consumer Recycle) and GRS (Global Recycled Standard) standards.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

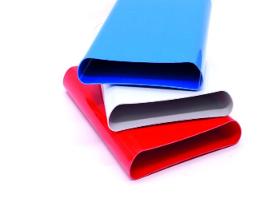

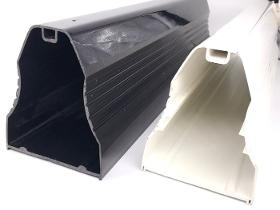

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,TPE/TPR, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg is a Chinese plastic extrusion products manufacturer custom making PVC soft and hard co-extrusion profiles according to customer’s design or sample. we can co-extrude profiles by Soft and Hard Co-extruding, 2/3(double or three) colors Co-extruding, 2 materials Co-extruding. We are focus on plastic extrusion custom services for worldwide customers, and have produced more than Thousands of plastic profiles & pipes for foreign clients in the past 15 years. At the same time, we have gained a wealth of experience, and the requirements for product quality have further deepened our understanding. Plastic extrusion products mainly use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE,TPE/TPR... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

TECHNIC MACHINES

Turkey

Our plastic sheet extruder machine lines have different production capacity range and we provide our sheet extrusion machine lines for different plastic sheet products so that we can match with our customer's requirements. We provide our sheet extrusion line for different raw materials such as pvc, pp, ps / polystyrene, pc / polycarbonate, hdpe / ldpe, pet and for other. Plastic Sheet Extruders by Raw Material - PET Sheet Extruder Machine - PP Sheet Extruder Machine - PE Sheet Production Line - PVC Sheet Extruder Line - PC Sheet Extrusion Machine - ABS Sheet Extruder Machine Plastic Sheet Extruders by Final Shapes - Rigid Sheet Extruder Line - Plastic Board Extrusion Machine - Foam Board Extruder Lines - Hollow Sheet Extrusion Machine - Corrugated Sheet Extruder Machine - Honeycomp Board Extruder Machine Just contact with us for other plastic sheet extruders according to your specific raw materials and shape, we will offer the optimum solution.

Request for a quote

TECHNIC MACHINES

Turkey

Our rattan extruder machines have different production capacity range and also capable to produce different rattan sizes, so that we can match different demand. You can produce with our rattan extruders different final product such as furniture and decoration etc. Plastic rattan raw material is mostly PE. PE has the highest stability if you compare with other plastic rattan raw materials alternative. Other most common raw materials for plastic rattan extrusion are PVC and PU. Where you can use plastic rattan ? - Rattan Chair - Rattan Table - Rattan Sofa - Rattan Coffee Table - Rattan Bench Just contact with us for your rattan extrusion machine research, we will provide the optimum solution for your research.

Request for a quote

TECHNIC MACHINES

Turkey

We offer our Plastic Extruder Machine Lines for various industries, including construction, food, healthcare, white appliances, and automotive sectors. The most common raw materials used on our plastic extrusion machine lines include PVC, HDPE, PET, EPDM, PP, EPS, LDPE, PE, ABS, PC, PS, and others. We provide as standard Plastic Extruder Machine Lines WPC Extrusion Machine Strap Extrusion Machine Sheet Extruder Machine Rattan Extrusion Machine Polystyrene Extruder Machine Polycarbonate Extruder Machine Edge Band Extrusion Line Gasket Sealing Extrusion Machine As Technic Machines, we offer our customers optimal solutions for their specific needs in plastic extruder machine research. We provide custom solutions using twin screw extruders, single screw extruders, triplex extruders, or co-extruders. Our specialized extrusion line solutions are tailored to the final product requirements of our customers.

Request for a quote

RHIMEX.COM

Netherlands

Rhimex supplies over 5000 rubber profiles from stock in factories in the EU. Glued or vulcanized corners, inflation profiles, and profiles in different colors are just a few of the many possibilities. If the rubber profile you are looking for is not available in our wide range, we can have it custom made for you, in specific lengths or, for example, in frames. For €95 we will make a tool for you for exactly the rubber profile you need. The possibilities are endless! Feel free to contact us, we are happy to help you! WWW.RHIMEX.COM #constructie #bouw #future #toekomstbestendig #maatwerk #industrie #industry4_0 #energietransitie #energytransition

Request for a quote

RHIMEX.COM

Netherlands

RENOVATION SEALS FOR WINDOWS AND DOORS Brush seals - Window seals - Sash rebate seals - Edge protection seals - Adhesive seals - Foam rubber seals - Steel frame seals - Door seals - U-profiles More than 2.000 profiles from EU stock. New tooling starting at EUR 95.- Delivery time 2/4 weeks. Several standard colours available. From 35 / 85 shore

Request for a quote

FATRA A.S.

Czech Rep.

Technical foils – foils from flexible PVC (PVC-P) manufactured from transparent and coloured, specially cut, printed material, with wide range of designs – applied in office and school haberdashery, health care, automotive, and packaging industry.

Request for a quote

INDUPLAST PLÁSTICOS DE INGENIERÍA

Spain

At Induplast we work with plastics for the food industry that have been approved by FDA regulations for contact with food products and we have engineering plastics with additives for metal detection that prevent contamination and guarantee traceability and compliance with migration limits. We also use high-performance machinery that allows us to obtain plastic moulds for food and food machinery, guaranteeing the best quality.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WUXI KAIJINHUA PLASTIC INDUSTRY CO.,LTD

Belgium

artifical grass recycled PP/PE/TPE coating machine, designed for decoration grass.Coating weight and width adjustable.

Request for a quote

FLEXPLAS

Turkey

Crafted for your profile in a perfect way Flexplas designs and manufactures turn-key extrusion lines for the manufacture of flexible tape and profile. We build all the machines and tooling systems that are necessary for production. Flexplas profile extrusion line boasts the latest technology enabling optimum performance at the highest line speeds. The whole extrusion system is controlled via a single master control panel including a large touchscreen PLC. With our complete equipment you can produce a wide range of hose diameters extending from small to larger, according to your need. Features: *High-speed extrusion line for the best quality profile and tape *Production of sizes as per customer need *Customized design to meet customer requirements *Master control panel with Smart PLC system with color touch screen. *Remote control of the complete line with one master control panel. *Downstream equipment can be separated and installed to another production line when necessary.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The Gneuss Processing Unit (GPU) is a modular configuration of different Gneuss products and technologies, which are combined in to a high performance extrusion line for the manufacturing of high quality products.

Request for a quote

BOSCH MANUFACTURING AND SERVICES BELGIUM

Belgium

we can safeguard a very high level of process control in our extrusion production lines because our vulcanization process is done in a salt bath. This means the temperature of vulcanization is stable and independent of external conditions. This way, we can produce rubber profiles of a very consistent and high quality. Co-extrusion: we can produce 2 rubber types (eg hard and soft) into 1 final product High geometrical accuracy High surface quality Can be tailored to customers' needs Possibility to apply different types of coatings (our patented PPC coating, graphite coating or chlorinated).

Request for a quote

FLEXPLAS

Turkey

FLEXPLAS DRIVEN CONVEYORS are designed to your specifications and adapted to your specific extrusion line and manufacturing requirements for maximum efficiency Flexplas take-away conveyors are designed with tilt/dump tables to be used when cutting flexible hoses and tubing. Typically located directly after cutting devices, Driven Conveyors enhance the cut length tolerance and cut quality by supporting and transporting the hose away from the cutter bushing at adjustable speeds typically more than line speed, eliminating accumulation and sorting confusion. The hose can then be optionally ejected by a pneumatic ejector system into a collection tray for operator removal or for coiling by a winding machine. The driven conveyor automatically discharges parts to a collection tray for this purpose. Our conveyors can be optionally configured for one side or dual side collection which is for double extrusion of the hose on the same extrusion line.

Request for a quote

FLEXPLAS

Turkey

Flexplas designs and manufactures turnkey extrusion lines for flexible PVC hoses reinforced with a spring steel wire and PVC coated spring steel wire helix. That is, we build all the machines and tooling systems that are necessary to produce “PVC-steel wire hose”. We realize this with our technological know-how and perfected craftsmanship. With our complete equipment you can produce a wide range of hose diameters extending from small to larger, according to your need. The complete line is automated, equipped with modern production management systems, and constructed as energy-efficient which includes the use of energy-efficient motors of the latest generation and LED lighting concepts. Furthermore, the machine has been designed to ensure a safe, easy, and time-saving operation after an accidental power failure or emergency stop. This also applies to relevant data items.

Request for a quote

IMPRINTA

Russia

Clotho ABS is a durable, composite, glass-fiber (13%) material that is heat resistant up to 100 °C. It was created to embody complex ideas even on simple personal printers. It is perfect for printing structural elements, functional parts, home products and car tuning. The material has an excellent surface of finished products without visible layers, minimal shrinkage and warpage, high printing accuracy, good adhesion to adhesive agents for ABS, easy post-processing, high modulus of elasticity.

Request for a quote

RIDAT

United Kingdom

Ridat Semi Automatic (SA) Vacuum Forming Machines offer, as standard high specifications, consistent production and a wide range of standard models and readiness to respond to requests for bespoke specifications. Fully automatic moulding processing sequences with manual placement of thermoformable sheet and removal of the vacuum formed product. Key machine features include: Ceramic heaters with multi-zone heater control for balanced heat Power assisted and timer controlled heater box movement Hinged clamp frame - powered by two air cylinders Mould chamber fully sealed to maintain vacuum pressure High capacity vacuum reservoir and pump for instant vacuum supply Microprocessor Controls and HMI Display CE Mark

Request for a quote

UCIESSE S.A.S.

Italy

PA 6, natural / black extruded is a tough material with high resistance to abrasion and impact. PA 6 is commonly used as a substitution material for bronze, aluminium and other non-ferrous metals, as it has significant weight advantages. PA 6, natural / black has a specific gravity of 1,15 g/cm3 and bronze has 8,8 g/cm3 making the comparative volume price very attractive.Using PA 6 also reduces lubrication requirements and is non-abrasive to mating surfaces.It features good mechanical properties.Nylons can absorb up to 8% water (by weight) under humidity or submerged in water. This increases the excellent shock and vibration resistance but can also lead to dimensional changes. Mechanical, electrical and dimensional properties are accordingly influenced by moisture absorption. Applications: Pulp and paper industry, offshore and marine, textile, general machine building, food industry, material handling, electronics, construction, mining, aerospace and many more.

Request for a quote

UCIESSE S.A.S.

Italy

POM is a semicrystalline thermoplastic and is characterized by a low coefficient of friction and good wear properties, unaffected by wet environments. POM offers good resistance to a wide range of chemicals including many solvents. Acetal provides high strength and stiffness coupled with easy machineability. POM-C - Delrin is also noted for its high mechanical strength, heat resistance and good antifriction properties. For parts which need to be dimensionally stable even exposed to humidity or wet environments, copolymeric Acetal offers better hot water, thermal and chemical resistance than homopolymeric Acetal. Applications: Food processing, agriculture, medical, electric, electronic, automotive, general machine building, transport and logistics, bottle and carwashing equipment, sports equipment, office machinery, textile. Available in colours: white: black: blu

Request for a quoteResults for

Extrusion of plastic materials - Import exportNumber of results

28 ProductsCountries

Category

- Extrusion of rubber and plastic (12)

- Extrusion, plastics - machinery (9)

- Plastic material processing (5)

- Plastics moulding (2)

- Electric motors and parts (1)

- Films, plastic (1)

- Food industry - machinery and equipment (1)

- Geotextiles (1)

- Hoses, pipes and tubes - plastic (1)

- Plastics - industrial products (1)

- Plastics - industrial raw materials (1)

- Prototypes, industrial (1)