- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- extruder machine for plastic

Results for

Extruder machine for plastic - Import export

TECHNIC MACHINES

Turkey

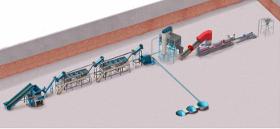

We offer our Plastic Extruder Machine Lines for various industries, including construction, food, healthcare, white appliances, and automotive sectors. The most common raw materials used on our plastic extrusion machine lines include PVC, HDPE, PET, EPDM, PP, EPS, LDPE, PE, ABS, PC, PS, and others. We provide as standard Plastic Extruder Machine Lines WPC Extrusion Machine Strap Extrusion Machine Sheet Extruder Machine Rattan Extrusion Machine Polystyrene Extruder Machine Polycarbonate Extruder Machine Edge Band Extrusion Line Gasket Sealing Extrusion Machine As Technic Machines, we offer our customers optimal solutions for their specific needs in plastic extruder machine research. We provide custom solutions using twin screw extruders, single screw extruders, triplex extruders, or co-extruders. Our specialized extrusion line solutions are tailored to the final product requirements of our customers.

Request for a quote

FLEXPLAS

Turkey

Cutting-edge FLEXT Series Extruders Flexplas proudly offer a wide range of FLEXT Series Single-Screw Extruders, either as a stand-alone extrusion machine or as part of a complete extrusion-system. All Flexplas extruders are characterized by an open, robust, and proven construction and high-quality craftsmanship. Screw diameters from 20 to 120 mm and process lengths of 25D to 30D combined with the appropriate screw geometry guarantee excellent plasticizing and maximum output for all popular thermoplastics. Digital, self-optimizing PID temperature control and a blower cooling system ensure outstanding process stability. Other features include Sliding hopper, ceramic heaters, screw designed for every type of material, energy-saving system, digital extruder control with touch screen. Flexplas FLEXT-series extruders boast many a feature as standard. We also present various customized options for our customers to meet their production requirements.

Request for a quote

TECHNIC MACHINES

Turkey

Our plastic sheet extruder machine lines have different production capacity range and we provide our sheet extrusion machine lines for different plastic sheet products so that we can match with our customer's requirements. We provide our sheet extrusion line for different raw materials such as pvc, pp, ps / polystyrene, pc / polycarbonate, hdpe / ldpe, pet and for other. Plastic Sheet Extruders by Raw Material - PET Sheet Extruder Machine - PP Sheet Extruder Machine - PE Sheet Production Line - PVC Sheet Extruder Line - PC Sheet Extrusion Machine - ABS Sheet Extruder Machine Plastic Sheet Extruders by Final Shapes - Rigid Sheet Extruder Line - Plastic Board Extrusion Machine - Foam Board Extruder Lines - Hollow Sheet Extrusion Machine - Corrugated Sheet Extruder Machine - Honeycomp Board Extruder Machine Just contact with us for other plastic sheet extruders according to your specific raw materials and shape, we will offer the optimum solution.

Request for a quote

CD AUTOMATION

Italy

The power controllers REVO TH are one of the latest born into the REVO family. Despite the formidable compactness, inside there are three independent SCR power units , which thanks to thyristor abundantly oversized in their junctions, they can manage currents up to 90A with a maximum voltage of 600V. Using Modbus and/or the more common fieldbus, multiple units can be connected to each other and therefore the ideal application area is the control of heating elements on multiple zones such as the simultaneous control of multiple IR lamps. Other application sectors can be for example: Multizone ovens Machines for plastics (extruders and extrusion lines, extrusion heads and hot runner mold control units) Packaging machines Ovens with long, medium and short wave IR lamp

Request for a quote

TECHNIC MACHINES

Turkey

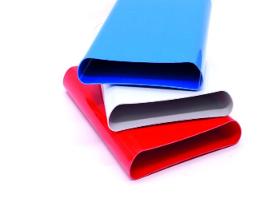

Our plastic strap production lines have different capacity options according to our customer's request. We have alternative solutions for plastic strap making machine with different capacity, price level and working raw material options according to our customer’s request. Plastic straps are used mostly in packaging process. PET or PP straps are used mostly in packaging process. Plastic strap extruder machine can work with raw material as PET and PP etc. Our plastic strap production line has different working speed options according to requested production capacity by our customers. Just contact with us for your plastic strap production line research, we will offer you the best and optimum solution.

Request for a quote

TECHNIC MACHINES

Turkey

Our rattan extruder machines have different production capacity range and also capable to produce different rattan sizes, so that we can match different demand. You can produce with our rattan extruders different final product such as furniture and decoration etc. Plastic rattan raw material is mostly PE. PE has the highest stability if you compare with other plastic rattan raw materials alternative. Other most common raw materials for plastic rattan extrusion are PVC and PU. Where you can use plastic rattan ? - Rattan Chair - Rattan Table - Rattan Sofa - Rattan Coffee Table - Rattan Bench Just contact with us for your rattan extrusion machine research, we will provide the optimum solution for your research.

Request for a quote

TECHNIC MACHINES

Turkey

We have options for WPC extruder lines, we provide WPC extruder machines with different capacity and different WPC final product as to our customers request. We offer WPC extruder machines for different product options. For example WPC decking extruder, WPC board production line, WPC profile extruder machine, WPC foam board production line, WPC flooring extruder machine and for other WPC extruder machines. Popular WPC Products - WPC Flooring - WPC Foam Board - WPC Board Panel - WPC Profile - WPC Decking Just contact with us for your WPC extruder machine research, we will provide the optimum solution.

Request for a quote

TECHNIC MACHINES

Turkey

We produce our Co Extruder machines for different plastic extrusion solutions. Such as with different extrusion screw design, screw length and diameter range according to final product of our customers and requested capacity. Our co extrusion machine can work with different raw material such as PVC, PP, PE, TPO, TPE, TPU, EVA, PET, PS, WPC, ABS, HDPE, PC, TPR, PEX, PA, etc. We provide for our customers the optimum solutions according to their final product on our Coex extruder, according to requested raw material and capacity demand.

Request for a quote

TECHNIC MACHINES

Turkey

We produce our triplex extruder machines for different plastic extrusion solutions. Such as with different extrusion screw design, screw length and diameter range according to final product of our customers and requested capacity. Our triple screw extrusion machine can work with different raw material such as PVC, PP, PE, TPO, TPE, TPU, EVA, PET, PS, WPC, ABS, HDPE, PC, TPR, PEX, PA, etc. We provide for our customers the optimum solutions according to their final product, raw material and capacity demand.

Request for a quote

TECHNIC MACHINES

Turkey

We produce our single screw extruder machines for different plastic extrusion solutions. Such as with different extrusion screw design, screw length and diameter range according to final product of our customers and requested capacity. Our single screw extrusion machine can work with different raw material such as PVC, PP, PE, TPO, TPE, TPU, EVA, PET, PS, WPC, ABS, HDPE, PC, TPR, PEX, PA, etc. We provide for our customers the optimum solutions according to their final product, raw material and capacity demand.

Request for a quote

TECHNIC MACHINES

Turkey

We produce our twin screw extruder machines for different plastic extrusion solutions. Such as with different extrusion screw design, screw length and diameter range according to final product of our customers and requested capacity. Our twin screw extrusion machine can work with different raw material such as PVC, PP, PE, TPO, TPE, TPU, EVA, PET, PS, WPC, ABS, HDPE, PC, TPR, PEX, PA, etc. We provide for our customers the optimum solutions according to their final product, raw material and capacity demand.

Request for a quote

CALDOR INDUSTRIAL HEATING SYSTEMS SRL

Romania

In all industry sectors, where heat is part of the production our products will be found. On injection moulding machines and extruders, for plasticizing of synthetic granules also for sealing of covers in packaging machines with diverse cup-geometry our heating elements deliver the heat. There are numerous applications, where our electrical heating elements are in operation. Our extensive product range of Temperature Sensors, Controllers as well as Ovens make our programme of delivery complete.

Request for a quote

MASFEN MANUFACTURING

Turkey

Extruder machine is used for melting, mixing plastic material. Masfen produces specific screw and barrel for material type, that provides perfect mixing and homogeneous. Our Extruders has 50kg/h to 1000kg/h capacity for PE,PEX,PP,PPRC type plastics.

Request for a quote

IRIS PACK

Poland

Extruder, Foil blowing machine price 20000 euro Producer: KWEEN B (TAIWAN) Year: 2007 Materials: LDPE, HDPE,LLDPE Foil Width (Max): 1200 mm Productivity: 50 kg/h Snail diameters: 55 Condition: good, can be viewed at work. https://youtube.com/shorts/5gASYmoffj4?feature=share

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

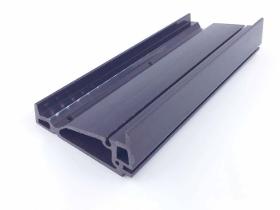

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. We provide a variety of extrusion process processing, cold extrusion, hot extrusion, two-color co-extrusion, three-color co-extrusion, soft and hard co-extrusion,can meet customer requirements of different products processing needs! If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,TPE/TPR, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNIC MACHINES

Turkey

We design our plastic recycling machine to give best solution for waste plastic recycling process with minimum energy consumption. According to our customer's request, we offer different capacity options. Our plastic recycle machine is used mostly for plastic film and bag recycling process. It can work with raw materials such as PE, PP, PVC, HDPE, LDPE, Polythene, Polystyrene PET and etc. As tp market demand, we design our machine for working even with pretty dirty waste plastic film and bag. Also we offer our customers fully automatic or semi automatic solution. So, we provide for our customers, the plastic recycling machine according to their requirements. Plastic recycling line main units, – Bale Opening Unit – Shredder Unit – Helezons – Washing Systems – Separator Units – Screw Loading Units – Friction Washing Units – Dewatering Machinery – Agglomeration System – Granulating Machinery – Big Bag Filling Unit

Request for a quote

INDUPLAST PLÁSTICOS DE INGENIERÍA

Spain

These materials offer numerous advantages when working with them, which is why they are increasingly being used in comparison to other alternatives such as metals. Technical applications require parts with very specific features. Research and development thus play an important role in obtaining innovative items.

Request for a quote

IMPRINTA

Russia

Create shapes that are limited only by your imagination. The new in-house-designed twin print head allows printing a model using two different materials with big volume.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

With automatic continuous punching machines, machine and tool merge into a high-performance system with high output and remarkable flexibility. Whether sealing profiles for the automotive industry, applications for furniture, or household appliances – complex trimming is often required here. Thanks to the Metzner automatic throughfeed punching machines, processing operations such as contour cutting, drilling and milling can be integrated into a throughfeed system. All these machines store all machining parameters and machine settings in a machining recipe. When starting production, an integrated barcode scanner activates all presettings on the basis of the working papers and simultaneously reports the correct tool and material on the machine display. The barcode also contains the required quantities and lengths. Thanks to well thought-out quick-change systems, tools and materials are generally changed within no more than 30 seconds, minimizing downtimes.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Preparation of the material components under vacuum and injection into an evacuated mold.

Request for a quoteResults for

Extruder machine for plastic - Import exportNumber of results

23 ProductsCompany type

Category

- Extrusion, plastics - machinery (10)

- Extrusion of rubber and plastic (3)

- Punching machines, plastic (2)

- Automation - systems and equipment (1)

- Films and sheets, plastic (1)

- Heating, industrial - installations and equipment (1)

- Injection, plastics - machinery (1)

- Mechanical engineering - custom work (1)

- Milling and turning of rubber and plastic (1)

- Plastic material processing (1)

- Plastics - machines and material for industry (1)

- Tubes and pipes, rubber and plastic (1)