- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- extruded films

Results for

Extruded films - Import export

WESTLAKE PLASTICS EUROPE

France

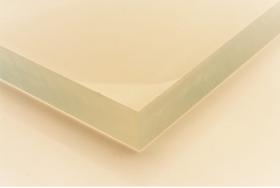

Thermalux® Polysulfone (PSU) is an amber colored, semi-transparent, heat-resistant, high performance engineering thermoplastic that offers higher heat resistance and better hydrolytic stability than polycarbonate (PC). It retains its good mechanical properties when exposed to steam and other sterilization techniques. We offer it in natural light amber in either rods, films and sheets.

Request for a quote

DISTRIBUCIONES JULMARSA S.L.

Spain

Sintered Extruded PTFE Film is a high modulus PTFE film manufactured by extrusion and sintering processes. The physical properties of sintered extruded PTFE film exceed the physical properties of skived PTFE films. Features/Benefits • High dielectric strength • High chemical resistance • Low moisture absorption • Resistance to permeability • High temperature insulation • High modulus • Operating temperature range -100°F (-73°C) to +500°F (260°C) • RoHS and REACH compliant Applications • High temperature wire and cable • Coil winding • Gaskets • Diaphragms

Request for a quote

DISTRIBUCIONES JULMARSA S.L.

Spain

Black Unsintered Extruded PTFE Film is engineered with a carbon based PTFE filler to enhance conductivity and facilitate the dissipation of static electricity. It can be used for shielding high temperature wires and cables, wall construction of convoluted hose or when carbon black offers color advantages over other black pigments. Physical properties and conductivity are maximized after sintering. Features/Benefits • Enhanced Conductivity • Outstanding heat and chemical resistance • RoHS and REACH compliant Applications • High temperature wire and cable • Convoluted hose

Request for a quote

ENOL FOLIEN GMBH

Germany

Top films, bottom films, thermoforming films and vacuum films for meat packaging, sliced meat packaging, cheese packaging etc. High-transparent multi-layer film laminations according to your specifications and requirements as top films, bottom films, thermoforming films as well as vacuum films. We deliver excellent solutions to protect and present your food products. available e.g. in lamination PA – PE – EVOH – PET – PP available as flexible film foil and rigid film Extruded or laminated films for thermoforming process available also as high barrier film with EVOH-coating available also with additional antifog-coating to prevent that the foil gets fogged from inside available also as film with additional UV barrier available also as peelable film (easy to open) available also as numerously resealable film unprinted or printed by flexo printing up to 8 colours or gravure printing up to 10 colours. films available also in dyed execution (different colours possible)

Request for a quote

EK-PACK FOLIEN GMBH

Germany

MANUFACTURING PROCESS: » Cast-Coextrusion MAIN APPLICATION: » Top Web FIELDS OF APPLICATION: » Food » Non-Food » Medical/Pharma (NOH Med) FEATURES/PROPERTIES: » Good flatness » High barrier against water vapor » High seal strength » Wide sealing range » High puncture resistance » High mechanical strength » Pasteurizable » NOH Med as a special version for medical/pharmaceutical applications

Request for a quote

EK-PACK FOLIEN GMBH

Germany

MANUFACTURING PROCESS: » Cast-Coextrusion MAIN APPLICATION: » Top Web FIELDS OF APPLICATION: » Food » Non-Food » Medical/Pharma (NOH Med) FEATURES/PROPERTIES: » Good flatness » High barrier against water vapor » High seal strength » Wide sealing range » High puncture resistance » High mechanical strength » Pasteurizable » NOH Med as a special version for medical/pharmaceutical applications

Request for a quote

EK-PACK FOLIEN GMBH

Germany

MANUFACTURING PROCESS: » Cast-Tandem-Extrusion or » Cast-Coextrusion MAIN APPLICATION: » Top Web FIELDS OF APPLICATION: » Food » Non-Food FEATURES/PROPERTIES: » Good flatness » High barrier against water vapor » High seal strength » Wide sealing range » High puncture resistance » High mechanical strength

Request for a quote

EK-PACK FOLIEN GMBH

Germany

MANUFACTURING PROCESS: » Cast-Coextrusion MAIN APPLICATION: » Side-sealed pouches for vacuuming and pasteurization FIELDS OF APPLICATION: » Food » Non-Food » Medical/Pharma (NBH Med) FEATURES/PROPERTIES: » Good flatness » High barrier against water vapor » High seal strength » Wide sealing range » High puncture resistance » High mechanical strength » Pasteurizable » Various tintings possible » NBH Med as a special version for medical/pharmaceutical applications

Request for a quote

EK-PACK FOLIEN GMBH

Germany

MANUFACTURING PROCESS: » Cast-Coextrusion MAIN APPLICATION: » Side-sealed pouches for vacuuming and pasteurization FIELDS OF APPLICATION: » Food » Non-Food » Medical/Pharma (NBH Med) FEATURES/PROPERTIES: » Good flatness » High barrier against water vapor » High seal strength » Wide sealing range » High puncture resistance » High mechanical strength » Pasteurizable » Various tintings possible » NBH Med as a special version for medical/pharmaceutical applications

Request for a quote

EK-PACK FOLIEN GMBH

Germany

MANUFACTURING PROCESS: » Cast-Tandem-Extrusion or » Cast-Coextrusion MAIN APPLICATION: » Side-sealed pouches for vacuum applications FIELDS OF APPLICATION: » Food » Non-Food FEATURES/PROPERTIES: » Good flatness » High barrier against water vapor » High seal strength » Wide sealing range » High puncture resistance » High mechanical strength » Various tintings possible » Also available as embossed structure

Request for a quote

CONSTAB POLYOLEFIN ADDITIVES GMBH

Germany

CONSTAB offers a wide range of masterbatches with which you can provide your BOPP films with the required or desired properties. There is a wide range of properties with which BOPP films can be provided for individual use. At CONSTAB you will find BOPP masterbatches for co-extruded films, matt films, for metallizable matt films, cigarette film and metallizable films, among others.

Request for a quote

FERPLAST SNC

Italy

CF SERIES - CONSTANT TEMPERATURE HEAT SEALERS WITH PEDESTAL AND FOOT PEDAL ( for multi-layer bags) THE CF SERIES of constant heat sealers with pedestal and operated by foot pedal, are ideal for sealing bags made of compunds, multi-layer films, co-extruded films, OPP, heat-sealable cellophane. It is not suitable for polyethylene films. Being operated by foot pedal, the hands are free to feed the machine. The sealing jaws of the type "hot bar" are equipped with resistance and temperature controller for controlling the temperature from 30 ° C to 200 ° C. The temperature of the sealing jaws is adjustable according to the type and thickness of the material to be sealed, and is kept constant by a heat thermo-regulator. The maximum sealable thickness, that always varies according to the type of sealable material, is 0.25 mm. (50 mm. total). Also available in CFN version with timer and acoustic signal at the end of sealing.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO can offer PEEK powders in various viscosities. It can be used for a variety of applications: semi-finished product extrusion, injection molding, compounding, filament and film extrusion, coatings. Our CoPEEK 012P is a high viscous, unreinforced PEEK for extrusion and injection molding, thus it is the standard type for the production of semi-finished products. CoPEEK 021P is medium viscous, unreinforced PEEK for injection molding. But it can also be extruded for the production of films and filaments. CoPEEK 085P is low viscous, unreinforced PEEK for the extrusion of films and filaments. It is also used as the basis for compounds and composites. Our CoPEEK can be processed on machines for thermoplastics without any problems. We recommend a processing temperature of 360 °C to 380 °C. BIEGLO CoPEEK is ISO 10993 certified for medical applications and also has FDA certification.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO can offer PEEK granulates in various viscosities. It can be used for a variety of applications: semi-finished product extrusion, injection molding, compounding, filament and film extrusion, coatings. Our CoPEEK 012G is high viscous, unreinforced PEEK for extrusion and injection molding, thus it is the standard type for the production of semi-finished products. CoPEEK 021G is medium viscous, unreinforced PEEK for injection molding. But it can also be extruded for the production of films and filaments. CoPEEK 085G is low viscous, unreinforced PEEK for the extrusion of films and filaments. It is also used as the basis for compounds and composites. CoPEEK 125G is very low viscous, unreinforced PEEK for the injection molding of thin-walled, complex components. It is also suitable for the production of highly filled compounds.

Request for a quote

MAGICAL FILM ENTERPRISE CO., LTD.

Taiwan R.O.C.

PETG has high transparency and good adhesion for printing, could be used for makeup bottles, containers, package film and etc. Mixed Polymers can also be extruded into sheet or films, made into plastic products by injection molding, or processed into Christmas tree leaves. Mixed Polymers can be mixed with virgin material, such as ABS, PP, PS and PMMA to extrude or inject plastic products.

Request for a quoteLIST TECHNOLOGY AG

Switzerland

The LIST KneaderReactor Technology fills the gab and successfully combines the benefits of conventional process equipment, e.g.… Extruder Thin-Film Reactor Continuous Stirred-Tank Reactor (CSTR) Rotary Disc Reactor …with many other process characteristics which are unique for LIST. It provides an exceptional toolbox for developing new innovative and economical products and processes helping our customers to stay up to date with process technology. Your benefits Effective self-cleaning to minimize dead zones, product accumulation and product degradation Excellent kneading and mixing for better homogenization Effective heat transfer High surface renewal efficiency Large free vapour volume Precise and uniform temperature control due to large heat transfer areas Continuous or batch processing Process intensification Processing of sticky and highly viscous products Residence time is independent from agitator speed Wide and flexible range of average residence times Wide turndown...

Request for a quote

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

Disposable dunnage bags made of 2-ply special paper and triple co-extruded PE film for a maximum load of up to 11.3 t.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FATRA A.S.

Czech Rep.

BOPET films Biaxially oriented polyethylene terephthalate (BOPET) films Fatra Tenolan® are extruded films with subsequent biaxial orientation. Films are designed for further processing in the packaging technology, electro-technical industry, for decoration purposes, as separation foils, etc. They are supplied in rolls or cut to size. Films are designed for direct contact with food and meals and they must comply with hygienic regulations in force. Processed materials PET Al PET (polyethylene-terephthalate) is a hard and clear polymer material with extremely good mechanical features. It shows excellent tear resistance; it can resist to high pressure volumes without braking, which is used in the production of packages for beverages – PET bottles. PET material is suitable also for the production of extruded foils. Subsequent biaxial stretching of the foil (in both directions) improves significantly the strength in both directions. It forms the required packaging material known for...

Request for a quote

PLASTIC UNION

Belgium

+ Thickness reduction up to 50% without loss of mechanical properties. + The film is very clear and brilliant + The film breaks all record on mechanical properties + The film has very good sealing properties on all sealing technologies and in all environments +The film can be extruded very thin : down to 12 µM ! + The film is electrostatically neutral

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The flexible PA/PE medium barrier composite films are suitable for classic applications such as thermoforming. Each layer performs an important function: The PA layer is the crucial factor for the mechanical strength of the packaging. Working as a barrier layer, it seals in the aroma and prevents the penetration of oxygen, thereby extending the shelf life of your product. The PE layer on the inside of the packaging functions as a sealing medium and is decisive for providing airtight seams and a proper skin sealing. It serves as a moisture barrier and, although it protects your product from drying out, it also prevents the uncontrolled absorption of moisture. The tie layer between the PA and PE layers has the task of reliably tying them together so as to prevent delamination, even at high or varying temperatures. Excellent puncture resistance and wide sealing range Co-extruded composite films by ALLVAC consist of up to 11 layers of polyamide and polyethylene

Request for a quote

MULTIPLASTICS (EUROPE) LIMITED

United Kingdom

HSF5425H is a bi-axially orientated, clear polypropylene two side Acrylic coated film. A co-extruded product giving hot tack, free seal type for large size and weight packages. This product is suitable where an attractive presentation, seal and high speed packing is required. Primary Markets Snacks • Sandwich Wraps • Baked Goods • Fruit & Vegetable • Confectionery Box Overwrap • Cosmetics • Spices • Pet Food • Film Bags • Print & Lamination

Request for a quote

MULTIPLASTICS (EUROPE) LIMITED

United Kingdom

HSF5475H is a bi-axially orientated, clear polypropylene two side PVdC coated film. A co-extruded product giving hot tack, free seal type for large size and weight packages. This product is suitable where a high gas, water and aroma barrier is required. Primary Markets Snacks • Confectionery • Box Overwrap • Cosmetics • Pouch • Film Bags • Print & Lamination

Request for a quote

MULTIPLASTICS (EUROPE) LIMITED

United Kingdom

HSF5400H is a bi-axially orientated, clear polypropylene one side Acrylic one side PVdC coated film. A co-extruded product giving hot tack, free seal type for large size and weight packages. This product is suitable where a high gas barrier, extended shelf life, attractive presentation and high speed packing is required. Primary Markets Snacks • Sandwich Wraps • Baked Goods • Fruit & Vegetable • Confectionery Box Overwrap • Cosmetics • Spices • Pet Food • Film Bags • Print & Lamination

Request for a quote

YENIADA FLEXO PRINTING MACHINERY

Turkey

Whale is online flexo printing machine with DC motor. Directly mountable on extruders, blowers , film shrinkers, etc... You can print on your film just when you are producing. You can print recycle marks , 1 color logos , instructions with this machine without another printing operation. The machine is CE certificated.

Request for a quote

POLIFILM GMBH

Germany

POLIFILM manufactures construction films and thermal plastic films which ensure reliable insulation and high living quality. We offer solutions for all fields of application - mono films, co-extruded products and complex individual formulas.

Request for a quote

POLIFILM GMBH

Germany

Our co-extruded silo films offer the optimum cover of grass or maize silage in bunker silos and thus ensure perfect conditions for the production of high quality feed. The effect of the films can be increased with the combined application of underlay films. Our silo films are available in the colours: black / black black / white green / white white / white green / black silver / green in widths of 4.00 m to 18.00 m.

Request for a quote

POLIFILM GMBH

Germany

In addition to adhesive coated protection films, POLIFILM is also offering coextruded, uncoated yet self-adhesive films since more than 12 years. These protection film solutions combine the film manufacturing process (film extrusion) and the adhesive extrusion in one process. The traditional process requires typically at least 2 steps. This co-extrusion process presents a clear productivity gain also for our customers. We develop co-extruded protection films together with our partner, who has a long time experience in the development and production of cast films. Our joint technological experience presents an ideal platform for the development of ever more demanding requirements of our customers now and in the future.

Request for a quote

POLIFILM GMBH

Germany

POLIFILM surface protections films have been successfully used for the protection of decorative laminates for decades. Depending upon the gloss level of the laminates low adhesion level films (for high gloss surfaces) or higher adhesion films (for rougher finishes) are used. Typically transparent films are used as they allow quality inspection of the decorative surface without a need to remove the films for this process. For 2D and 3D applications with special requirements we offer several solutions. Co-extruded, uncoated protection films present a good solution for these requirements.

Request for a quote

POLIFILM GMBH

Germany

Our co-extruded silo films offer the optimum cover of grass or maize silage in bunker silos and thus ensure perfect conditions for the production of high quality feed. The effect of the films can be increased with the combined application of underlay films. Our silo films are available in the colours: black / black black / white green / white white / white green / black silver / green in widths of 4.00 m to 18.00 m.

Request for a quoteResults for

Extruded films - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Films for packaging (3)

- Cables and wires, electric and telephone (2)

- Granules for plastics (2)

- Additives for plastics industry (1)

- Flexography - machines (1)

- Package sealing machinery (1)

- Plastics - semi-finished products (1)

- Polymers (1)

- Printing - flexography (1)

- Vehicles - accessories and equipment (1)