- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- expansion joints

Results for

Expansion joints - Import export

NOVELTY STEEL

Turkey

Dampers play a crucial role in the functionality of industrial ductwork as they are designed to control the flow of air or flue-gas within the ducts. The primary purpose of most dampers is to act as shut-off dampers. This means they are either fully open or fully closed depending on the operational requirements. However, some dampers are specifically installed to modulate the gas flow, allowing them to function in various partially open positions. The variability in damper functionality caters to different operating scenarios and provides flexibility in managing the flow of air or flue-gas through the duct system.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Penstocks are used to discharge the headwater from a reservoir. Due to thermal and dynamic effects on the pipelines which are usually run underground in the mountain, compensation for expansion is necessary. By fitting an expansion joint, slow creep movements, eccentricity, dilation and also pipe misalignment can be reliably absorbed. The MANOY® system seal WP, type 436, was specially developed for leakagefree operation of an expansion joint.

Request for a quote

NOVELTY STEEL

Turkey

Expansion joints serve a crucial role in industrial ductwork by facilitating the controlled expansion and contraction of ducts. Their primary function is to accommodate thermal movements within the ductwork system. They mitigate thermally induced stresses by allowing thermal movements in a relatively unrestricted manner. Expansion joints contribute to the overall flexibility and structural integrity of the system which is essential in preventing the build-up of stress that could otherwise lead to damage in equipment, ductwork, and supporting structures.

Request for a quote

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

We produce expansion joints for all industrial sectors to take up vibrations, for noise absorption, or to compensate distortion by axial, lateral or angular movements. Our expansion joints are available in various versions and numerous elastomers variants in inner diameters from 25 mm to 1600 mm. Testing certificates of all well-known testing institutes are at hand. TYPE II Single or multiple flutes with rubber/fabric flange. Various elastomers qualities. ND 32 to ND 1600, Standard length n 250, 300 und 350 mm, Standard pressure stage 10 bar. TYPE V and TYPE VII Single wave with rubber sealing bead. Various elastomers qualities. ND 32 to ND 600. Standard pressure stage 10 bar. TYPE V Standard length 100 mm TYPE VII Standard length 130 mm HKS and HKA Per heating standard DIN 4809. COUPLING EXPANSION JOINT Single or multiple flutes, in various elastomers qualities. ND 25 – ND 750, any length for pressures from –0,8 to +15 bar, with clamping band. RUBBER-METAL PIPE...

Request for a quote

BITUMER SP. Z O.O.

Poland

Bitumer Flexigum PU is a one-component bitumen-polyurethane compound that forms a permanently flexible and chemically resistant fastening and stress transfer compound. Bitumer Flexigum PU finds its use in: •for continuous resilient fixing of the rail as a subfloor, •rail fastening compound and as a lagging for the underfloor, •for making permanent and flexible expansion joints between concrete slabs and elements made of steel, •filling the gaps located between the road strip and the rail, •for filling concrete-to-concrete joints •filling joints, gaps, cracks and expansion joints in heavily worked asphalt and concrete pavements ( e.g., curbs on bridges), •filling joints "working" on steel and concrete bridges and other pavements characterized by strong movements.

Request for a quote

GAMBIT LUBAWKA SP. Z O.O.

Poland

Industrial processes require a possibility of a flexible joint of two or mere components that move against each other, in such a way as to maintain tightness of the connection. The solution of this problem are compensator fabrics produced by Gambit in accordance with individual needs of users or installation designers. They are used as flexible joints compensating thermal deformations, side shift, and vibrations, while muffling and reducing transfer of noise across the installation. Compensators are used in power plants, gas turbines, chemical industry, petrochemical industry, paper industry and cement industry. More and more compensators are used in exhaust gas treatment and desulphurisation. Our compensators are made of materials resistant to both high temperatures, up to 1000oC, and aggressive chemical media. Working pressure of compensator fabric is -0.2 to 0.3 bar.

Request for a quote

TURKOGLU

Turkey

Expansion Joints Group *** AXIAL-LATERAL METAL BELLOWED EXPANSION JOINT ( WELDED NECK) / AXIAL-LATERAL METAL BELLOWED EXPANSION JOINT ( FLOATING FLANGE) / AXIAL-LATERAL METAL BELLOWED EXPANSION JOINT ( FIXED FLANGE) / EXTERNAL PRESSURED EXPANSION JOINT ( WELDED NECK ) / EXTERNAL PRESSURED EXPANSION JOINT ( FLANGED ) / VIBRATION ABSORBER METAL EXPANSION JOINT ( TIE-ROD) / PIPE EXPANSION JOINT / RUBBER EXPANSION JOINT ( FLANGED) / RUBBER EXPANSION JOINT ( THREADED) / DILATATION AND EARTHQUAKE EXPANSION JOINT (WELDED NECK ) / DILATATION AND EARTHQUAKE EXPANSION JOINT (FLANGED ) / LIMIT RODS DILATATION EXPANSION JOINT (WELDED NECK / GROOVED END ) / LIMIT ROD DILATATION EXPANSION JOINT (FLANGED)

Request for a quote

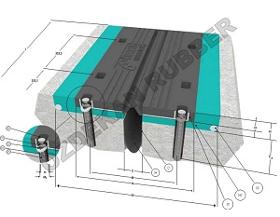

OZDEKAN RUBBER CO.

Turkey

The Ozdekan EX are waterproof expansion joints that allow absorption of the deck movements. These joints are manufactured with rubber elements and restrained to the structure with proper anchor bolts. The reinforcing metal profiles made of steel are completely inserted and vulcanized to the rubber. This process is a total guarantee against corrosion and allows a longer life to the product. The rubber compound, too, has been intentionally formulated to resist the oil, grease, petrol, salt and sand, without besides, suffering premature ageing phenomena due to sun rays, salt and snow. All the joints follow the deformations and movements of the structure (the movement can exist with every skew angle from 0° to 90°) by shear deformation of the rubber elements. Anchor bolts, made of steel and protected with anticorrosion treatments, absorb the elastic reactions and all the other kind of mechanical solicitations. www.ozdekan.com

Request for a quote

KBC DIFFUSION

France

The KBD Diffusion team listens to its customers and has experience in recommending building equipment and offers you custom-made metal plates. 20 mm thick, they are sized to the size of your formwork panels, whatever their brand: SATECO, OUTINORD, HUSSOR, COSMOS, DEKO ... They are equipped with tightening nuts corresponding to the dimension of your rods. Thanks to their lifting ances, they are easy to crane and move. They can be delivered with an alignment angle fixed to the side of the sheet of your choice to facilitate their alignment. These sheets allow you to quickly cast your expansion joints without wasting cardboard and polystyrene. They make it possible to gain flexibility while maintaining high pouring rates. In addition, thanks to these expansion joint sheets, you can use the concrete of your choice and the pouring technique that best suits your site.

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

The Kinematic chain system is a building technology which creates an elastic connection between the decks both longitudinally and transversally thus ensuring a "hinge" behaviour against flexural stresses in the connection area. This system allows all the longitudinal deformations of the deck resulting from shrinkage, creep or temperature changes, to focus on one point, usually the centreline of the engineering structure or by one of the abutments. The Kinematic chain system thus allows to exploit all the advantages offered by continuous structures (seismic behaviour, reduction in the number of joints without giving up those offered by the statically determinate structures consisting of simple beams, design and construction simplicity). It is suitable both for new and existing engineering structures, especially when their seismic adjustment is necessary. It allows to manage longitudinal seismic stresses transferred to the bridge deck/piers interface.

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

These joints are obtained by opposing two finger-shaped metal elements: each is fixed to its head, thus ensuring, thanks to a suitable interpenetration, continuity of the carriageway in case of expansion/shrinkage. Their static layout can act as a beam on two bearings when the finger rests on both heads or as a shelf when it overhangs a head. A specific device is needed, usually a gutter, to ensure the gap watertightness. Special attention should be paid to the alignment during the installation phase and to the head anchoring, especially in the case of shelf layout. Except for special arrangements, this type of joint permits limited transverse displacements. TIPOLOGIE: SFE 90/65 GP FE C

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

These joints are normally made up of an elastomeric structure in which, by a curing process or other technological process, metal profiles are inserted to change, at set points, the stiffness or bearing capacity of the elastomeric structure. There are two main sub-groups depending on the mechanism which is used to obtain the expansion/shrinkage capacity of the joint, namely: by elastic deformation, with shear stress, of appropriately prepared suitable elastomeric areas; by elastic deformation of the elastomeric profiles the designed geometry of which is changed by normally flexural stresses. A characteristic of this type of joints is the presence, at the level of the congested surface, of a series of transverse gaps required for the development of the necessary elastic deformations. TYPES: RAN 50 S GPE 50/100/150 GPE 200/250 GPE 300 GPE 400 RAN P ALFA 25

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

They permit displacements and rotations between abutted structural parts, ensuring continuity of the carriageway and watertightness. They come in a wide range of formats, each format having a certain movement range to accommodate, with only the types of materials used remaining constant. Based on a design of reinforced rubber modular elements, FIP INDUSTRIALE expansion joints offer the following advantages: simple installation simple and cost-effective inspections and maintenance minimal noise and vibration ultimate comfort for passengers in transit smooth running surface optimum functioning and durability of all components minimal interference with the structure format easily adjusted to many shapes to accommodate layout of structure and design engineers' preference several different types of anchorage to suit customer requirement. The series of expansion joints available are labelled as follows: Reinforced rubber road joints Finger road joints Under pavement road joints Re

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALPIN RUBBER AND PLASTIC TECHNOLOGIES

Turkey

Flexible connectors, rubber expansion joints, play a crucial role in absorbing movement, vibration, and noise within piping systems. These joints adeptly accommodate thermal expansion, contraction, and misalignment while steadfastly maintaining a tight seal.

Request for a quote

FLEXOMAT GMBH

Germany

Angular expansion joints absorb movements perpendicular to the bracing lane. The reaction forces caused by the internal pressure are absorbed by the hinge frame. In pipelines of larger nominal size and high pressure only tensioned angular expansion joints in the form of hinge-systems are able to absorb the expansion. Thus, for pipelines expansion joints are only installed as hinge-systems (combination of either 2 or 3 expansion joints). Those are L-, U- or Z-shaped. This requires additionally a 90 ° redirection of the pipeline. Thereby, stress due to inner pressure will be absorbed by the hinge tensioning. In case those systems cannot be applied due to missing space, special-purpose solutions like pressure-balanced expansion joints can be installed.. Types of design for angular expansion joints: Single hinge angular expansion joint for movements in one plane gimbal hinge angular expansion joint for omnidirectional movement

Request for a quote

FLEXOMAT GMBH

Germany

Lateral expansion joints absorb movements vertical to the bracing plane. The reaction forces caused by the internal pressure are absorbed by the joint mounting. Under internal pressure expansion joints generated pressure reaction forces. For a better understanding, the following considerations with different diamaters, pressures and resulting from it the forces: DN 150 -> 25 bar ~ 80 kN = 8 t DN 300 -> 10 bar ~ 100 kN = 10 t DN 1000 -> 1.5 bar ~ 130 kN = 13 t Due to high forces, movements in pipelines of higher nominal size and higher pressure can only be absorbed with braced expansion joints. Applying braced expansion joints pressure stress can be absorbed, while fixed bearings can be dimensioned smaller. In case a 3-hinge-system cannot be applied due to missing space, special-purpose solutions like pressure-balanced expansion joints can be installed. Types of design for lateral expansion joints: ball bearing types with tie rods for all-side movements cross hinged types for...

Request for a quote

FLEXOMAT GMBH

Germany

Certain specialised areas of various industries require at times applications which cannot be adequately realised by the use of standard components. Specially designed expansion joints are used in these cases. The following specific design types are offered in addition to the standard series: pressure balanced expansion joints for axial and lateral movement elbow-conected pressure balanced expansion joints chamber expansion joints expansion joints, pressure applied externally expansion joints with PTFE single used expansion joints expansion joints for food industrie outside material: 2.4610 inside material: PTFE (s=5mm) DP 10 bar DT 230° C ax. mov. +/-30 mm

Request for a quote

FLEXOMAT GMBH

Germany

Certain specialised areas of various industries require at times applications which cannot be adequately realised by the use of standard components. Specially designed expansion joints are used in these cases. The following specific design types are offered in addition to the standard series: pressure balanced expansion joints for axial and lateral movement elbow-conected pressure balanced expansion joints chamber expansion joints expansion joints, pressure applied externally expansion joints with PTFE single used expansion joints expansion joints for food industrie chamber expansion joints DN50 / DN150 / DN200 DP inside 6 bar DP outside 4,5 bar DT 155° C ax. mov. +/-15 mm lat. mov. +/-10 mm

Request for a quote

FLEXOMAT GMBH

Germany

Universal expansion joints absorb axial, lateral and angular movement simultaneously. Installation is primarily in the low pressure area. Using a guide tube protects the metal bellows from abrasive media or flow-induced oscillations. The reaction forces caused by the internal pressure must be absorbed by sufficiently dimensioned anchor points.

Request for a quote

FLEXOMAT GMBH

Germany

Axial expansion joints compensate assembly tolerances and thermal longitudinal expansion in the direction of the tube axis. Depending on the design, they can be impinged with pressure internally and externally. Using a guide sleeve protects the metal bellows from abrasive media or flow-induced oscillations. The reaction forces caused by the internal pressure must be absorbed by sufficiently dimensioned anchor points.

Request for a quote

NORELEM FRANCE

France

Profile guide rails can be screwed on from above. The profile guide rails are available in four sizes and one or more carriages can be assembled on them. 4row versions with round arch profile. The tracks of the profile guide rails are set below an angle of 45° and thus can carry loads from all directions. The profile guide rails correspond to the market standard and can replace linear guides of the same design by other manufacturers. On request Lengths up to a max. 3960 mm.

Request for a quote

NORELEM FRANCE

France

Body carbon steel. Balls roller bearing steel. Diverters plastic. Standard guide carriage with recirculating ball guidance precision N not preloaded (Z0). With doublesided end seal. 4row versions with round arch profile. The profile guide rail tracks are arranged at 45° and can accept loads from all directions. High dynamic values v = 5 m/s. Applicable temperature in continuous use max. 80 °C. On request Various precision and preload classes. Drawing reference 1) ground ref. edge

Request for a quote

KOREMA® GMBH & CO.KG

Germany

Each expansion joint is tailor made. Layers of material are assembled on a frame which conforms exactly to the required profile. Bellows type expansion joints incl. or without reinforcing rings/frames. Diaphragms Expansion joints for varying cross sections and transitions. Construction from round to rectangular Construction according to drawings Non-standard high temperature seals Compound movement

Request for a quote

KOREMA® GMBH & CO.KG

Germany

The number of patents awarded to KOREMA® such as SIMIFLON® reflects an ongoing commitment to long term development of specialty materials which have opened new horizons and perspectives for the future. SIMIFLON®, (light colored material) is designated foodstuff quality and certified according to § 177.2600/177.1550 CFR of US Food and Drug Administration (FDA) as well as to EU Regulations EU 2002/72/EG and EU 10/2011.

Request for a quote

KOREMA® GMBH & CO.KG

Germany

This is the most installed version of the fabric expansion joints (KOREMA® type A3 or AC3 as well as B3 or BC3). The name »flange-type« is used for expansion joints located between pipe or duct end flanges. For existing plants, the flange design varies according to customers’ requirements or depending on the constructed steel design. For innovative designs KOREMA® will identify the suitable technical and economical solution. Special design: supplied as »open« multilayer expansion joint. On-site service available exclusively from the KOREMA® service team. Insulation is incorporated to protect the expansion joint against abrasion as well as for thermal insulation. The choice of insulating material, either mineral wool or ceramic felt, depends on the design temperature. For operation at or below dew point, a vulcanized elastomeric layer is available. Pre-assembled units, complete with liners and clamp bars, are available.

Request for a quoteResults for

Expansion joints - Import exportNumber of results

92 ProductsCountries

Category

- Expansion joints - non-ferrous metal (6)

- Expansion joints - ferrous metal (5)

- Industrial piping (4)

- Metal straightening machines (4)

- Bitumens (3)

- Hardware, building construction (3)

- Tubes and pipes, rubber and plastic (3)

- Ceramics, refractory (2)

- Pipes and tubes, stainless steel (2)

- Waterproofing construction products (2)

- Air treatment - equipment and systems (1)

- Central heating systems (1)

- Compensators (1)

- Concrete preparing - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Extrusion of rubber and plastic (1)

- Façade work contractors (1)

- Forming - steels and metals (1)

- Gas and oil - exploitation (1)

- Pipe and tube fittings - ferrous metal (1)