- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- envelope machines

Results for

Envelope machines - Import export

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 2015 folding- and enveloping machine computer control with touch screen 2 x feeder A4 1 x feeder attachment up to 2.000 cycles / h Delivery time: immediately from stock Ref: NE230076A Please ask for price. We ship and install worldwide!

Request for a quote

FERPLAST SNC

Italy

Vacuum packaging machine with trolley and double lateral sealing bars, made of stainless steel (AISI 304). Equipped with digital panel and volumetric electronic sensor for the steady control of vacuum. Volume increased chamber and convex lid for a max eight of 250 mm. The vacuum pump of 40m3/h with three-phase 380V motor ensures high productivity. The two side bars with a length of 60 cm allow to pack more bags simultaneously (on one or both of the bars), reducing packing times. Is however possible to use it with a single bar. The DZ 600 2S packaging machine is also used for the vacuum seal and the jars of creams, jams, etc .. The vacuum chamber utilizes specific smooth envelopes for vacuum. Vacuum machines can be equipped with gas injection system (MAP). Each sealing bar is equipped with two nozzles which introduce gases in different quantities, so the machines are suitable for the packaging of one single use for each sealing bar.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This fully automatic labeling line is suitable for reliably applying self-adhesive labels to various products such as envelopes, catalogues, magazines, etc. The machine is equipped with a completely overhauled rotary feeder from CMC, which we installed as a self-sufficient unit with a new vacuum pump and motor in a stable frame made of aluminum profiles. We then paired them up with a new vacuum table with electric height adjustment and an "Alpha Compact" labeler from BLUHM/WEBER mounted on it. Together with a new machine control system these modules can be assembled into a fully automatic labeling line with which our customer can process products up to 43 cm in length at high speeds (up to 70 m/min). Our systems can be freely configured according to your needs. Tell us your requirements so that we can present a concrete solution proposal.

Request for a quote

AUTOMATION & ROBOTICS (A&R)

Belgium

The AutoPacker is designed for use in mid to large volume prescription laboratories. After the job-identification, the lenses are unloaded from the job tray and centered. An envelope type is chosen from the magazine out of eighteen different envelope types, the lens is inserted in the envelope, and a label is printed and applied to the flap of the envelope which seals the envelope shut. Before loading the packaged lens into its original job tray a check is made to ensure the envelope is not empty.The machine is also capable of packing cut lenses. The 600 lenses per hour capacity and the completely automatic cycle which avoids any mispackaging, coupled with our years of experience in the field of packaging RX glasses are proof of its value. This machine is best utilized after the Automatic Control and Inking Unit.

Request for a quote

MARTIN GROUP SRL

Italy

This envelope is used in the packaging sector because it allows the item to be enveloped both in the upper part and at the bottom. The welding can take place in the upper part both in the horizontal and inclined position. Moreover, the machine may also be sold separately should the customer use pre-cut envelopes and thus should only the bottom of the envelope be sealed. Finally, with our envelope machine welding is environmentally safe without any production of fumes.

Request for a quote

SOPEM

Belgium

Year - 1969 Blank-fed envelope machine with window - dextrine and latex gumming

Request for a quote

SOPEM

Belgium

Year - 2005 Two colour envelope overprinting machine

Request for a quote

SOPEM

Belgium

Year - 1960 Large-size envelope machine with dextrine gumming of the closing flap. Sizes: Mini = 110 x 130 mm - Maxi = 280 x 400 mm

Request for a quote

SOPEM

Belgium

Year - 1983 Envelope machine - with 1 inside + 2 outside flexo print units - with window station - dextrine gumming - no outside side flaps

Request for a quote

SOPEM

Belgium

Year - 1960 Large-size envelope machine with one Inside flexo print unit and gumming of the closing flap - Sizes: from 110 x 130 mm up to 200 x 355 mm

Request for a quote

SOPEM

Belgium

Year - 2001 Reel-fed envelope machine with 6 flexo print units + W+D splicer + window station with window film W+D splicer - outside side-flaps - dextrine gumming

Request for a quote

SOPEM

Belgium

Year - 1974 Large-size envelope machine with one Inside and one outside flexo print unit - dextrine gumming of the closing flap - Sizes: from 125 x 175 mm up to 305 x 420 mm

Request for a quote

SOPEM

Belgium

Year - 1984 Dextrine gumming machine for envelopes and pockets

Request for a quote

SOPEM

Belgium

Year - 2011 Blank-fed envelope and Pocket machine - 3 flexo print units - window station - dextrine gumming - Hot-melt Peel & Seal

Request for a quote

SOPEM

Belgium

Year - 2004 Envelope and Pocket machine working from blanks - flexo printing units - window station - dextrine and Peel & Seal hot-melt

Request for a quote

SOPEM

Belgium

Year - 1983 Machine for envelopes without window - dextrine gumming - one Inside and two outside flexo print units

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

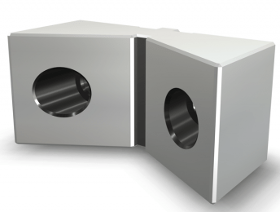

Easy machining of round workpieces High precision and high clamping force Wide range of accessories for flexibility Maximise your machining envelope Fixed v-jaws for the SVF range of flexible vices. There are bolt-on hard v-jaws to fit all types of fixed jaw in the SVF range including wedge type and non-wedge type. These v-jaws have a centre key for accurate positioning.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

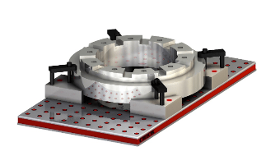

Maximise your machining envelope High precision and high clamping force Wide range of accessories for flexibility Clamp single large or multiple small workpieces Clamps to suit OK-Vise Multi-Rail. Multi-Rail can accommodate OK-Vise clamps, stops, parallels and other accessories to clamp multiple components and maximise your milling work area. All the clamping and location elements on the rail can be positioned according to the size and shape of the workpieces to swiftly adapt from clamping multiple small workpieces to clamping single large workpieces. These clamps are available in a range of styles and applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Maximise your machining envelope High precision and high clamping force Wide range of accessories for flexibility Clamp single large or multiple small workpieces Workstops to suit OK-Vise Multi-Rail. Multi-Rail can accommodate OK-Vise clamps, stops, parallels and other accessories to clamp multiple components and maximise your milling work area. All the clamping and location elements on the rail can be positioned according to the size and shape of the workpieces to swiftly adapt from clamping multiple small workpieces to clamping single large workpieces. These stops are available in a range of styles and applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

A Chick Workholding Foundation Plate is tailored to fit the machine’s specifications. A standard grid pattern to simplify designing, cataloguing and utilisation of fixtures, providing consistency and repeatability to set-ups. Length and width tailored to the machine’s work envelope. Precision ground cast iron to 35mm thick. 50mm spaced holes, drilled and tapped, for use as both location and hold down. Sealed with chip plugs. An alpha-numeric labelling system. Minimises set up time from workholding system to system. Machine interface mounting holes, customised for each machining centre.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Our latest machine is the VTC-300 CII which is a highly versatile vertical machining centre with a large 2000 mm table cross dimension and high-speed rapid traverse of up to 36 m/min. Productivity and efficiency are greatly improved as the machine work envelope is separated into 2 work areas. This allows the machine to be in cycle, in one work area, while a part is being set up in the other work area.

Request for a quoteResults for

Envelope machines - Import exportNumber of results

22 ProductsCountries

Company type

Category

- Machine tools - metal machining (5)

- Screw cutting - steels and metals (4)

- Custom packaging (1)

- Finishing and binding - machinery and equipment (1)

- Food packaging (1)

- Grinding - steels and metals (1)

- Industrial sheet metal work (1)

- Medical and surgical optics - instruments (1)

- Packing and packaging - machinery and equipment (1)