- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- endless belt

Results for

Endless belt - Import export

UGUR MAKINA CRUSHING & SCREENING

Turkey

Belt conveyors are particularly successful in transporting bulk materials such as mineral ores, stone, sand and grain at high capacities and over long distances. A belt conveyor consists of an endless belt stretched between two drums. Belt conveyors are usually the most suitable solution when stacking material needs to be transported over long distances without stopping. They are used horizontally or with a low slope. The material to be transported can be sand or granule.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

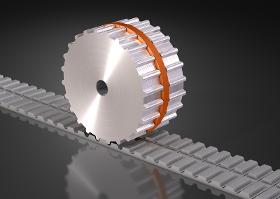

Neoprene timing belts are manufactured in a sophisticated process with state-of-the-art production engineering. They are made of chloroprene with glass-fiber cords and protective fabrics on the carrying surface.The high-performance timing belts of the Premium Series were especially developed for heavy-duty and high-speed power transmission tasks. Improved materials and an optimized combination of materials provide even more performance.Profiles: MXL, XL, L, H, XH, XXH DXL, DL, DH 2M, 3M, 5M, 8M, 14M, 20M D5M, D8M, D14M 3MP, 5MP, 8MP, 14MP (Premium Series) S3M, S5M, S8M, S14M, DS8M Properties: Form-fit, synchronous running Longitudinal stability, negligible elongation Low noise and resistant to abrasion Maintenance-free Positional accuracy, isogonic Flexural fatigue strength High belt speed

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

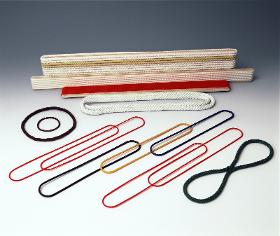

Our endless turned round belts are wound either out of one homogeneous strand or one cord and spliced endlessly without thickening. For special applications, it is possible to vulcanize the inner splice or to make a special splice based on our in-house engineering methods. This increases the tensile strength by up to 60%. In elastic types, the core is welded. In view of their special structure, twisted round belts exhibit very quiet running properties, are extremely flexible and, thus, make possible very small minimum pulley diameters of 3x belt diameter. For several types, speed up to 70,000 rpm is possible; however, the speed of 60m/s should not be exceeded. Elastic types: PU, Vulkollan Semi-elastic types: PA.6, Set-Polyester, Nylon, HE Types with limited extensibility: Polyester, Nomex, Nomex-PTFE, Polyester-PTFE, Kevlar/Twaron, PA.6 anti-static, PBO

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Endless extruded round belts Our endless extruded round belts are ideal for low power requirements. They are elastic power transmission elements that do not need cost-intensive tensioning devices. In view of the special production process, they do not have any welding seams or terminal connections and run very smoothly. Moreover, they allow a minimum pulley diameter starting from 5.5 x belt diameter. Our types E80, V75, C70 and P82 are made of specially selected and dynamically tough materials. In addition, type E80 also is antistatic to a limited extent and has a resistance value of about 106 Ohm; thus, it is excellent for use in electronic devices and chip production. Available diameters: 1.8mm - 7mm Available lengths: 40mm – 1,610mm Temperature resistance: -20°C - +160°C Coefficient of friction: 0.35µ - 0.9µ* Maximum tension: >100N

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

easy drive® track timing belts can be made from the complete range of polyurethane and neoprene timing belts: in open lengths, endless welded, for form belts, endless Flex or wide timing belts, in almost any length and width. The directional guiding, with groove in tooth, is either already integrated in the timing belt during production or added later. These timing belts exhibit the same properties as standard timing belts. However, in addition, axial movement is prevented and the zero-play guiding leads to high directional stability. Advantages • Universal application instead of flanged pulleys or special toothed belt guides • Can be used with any tooth shape or belt pitch • Can be combined with any material – steel, aluminium, grey cast-iron or plastics • For polyurethane and also for neoprene timing belts • Maximum directional stability, without lateral play, inaccurate running or drift

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

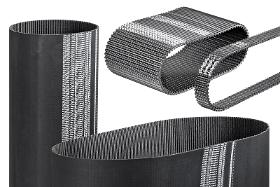

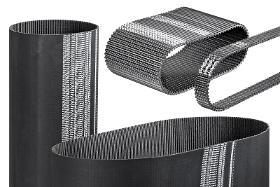

We use many different welding methods to produce endlessly spliced conveyor and process belts, always depending on the material and intended application. The endless splice punched finger splice stepped finger splice multilayered stepped splice conical splice The mechanical fastener Steelgrip fasteners, stainless steel Wire hooks, steel or stainless steel Polyester zip splice Self-lock fastener, stainless steel Plastic splice Nieka fastener Bonded wire hooks PVC/PU Minet fasteners

Request for a quote

WMC SINTERSTAR AG

Switzerland

Flexible endless abrasive belts + holder with corundum with diamond

Request for a quoteFAUDI GMBH

Germany

Advantages High flow rate Various endless-filter belts or non-woven fabric can be used Cleaning system for endless filter belts Highly economic Area of application Vacuum filters are used for the cleaning of coolants, e.g. for central filter systems with high flow rates and machining processes like turning, drilling and grinding. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid without Filtration degree 30-100 µm Medium oil and emulsion Filter material filter belt

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Neoprene endless molded timing belts (form belts) XL

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Neoprene endless molded timing belts (form belts) MXL

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Neoprene endless molded timing belts (form belts) STD S8M / S14M / DS8M

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Neoprene endless molded timing belts (form belts) STD S3M / S5M / S8M

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Neoprene endless molded timing belts (form belts) HTD D5M / D8M / D14M

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Neoprene endless molded timing belts (form belts) HTD 8M / 14M / 20M

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Neoprene endless molded timing belts (form belts) HTD 5M / 8M

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Neoprene endless molded timing belts (form belts) HTD 3M

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper PU Flex timing belts are extruded of abrasion-resistant polyurethane and high-strength steel cords, aramid cords or high flexible steel cords and VA steel with endless winded cords. In these belts the cords are helically spooled. These timing belts can be used for all kinds of power transmission applications because of their high power transfer, and their high flexibility make them suitable for synchronous transport and positioning applications. By using standard polyurethane and such other belt materials as polyurethane that is cold resistant, heat resistant or suitable for contact with foodstuffs a wide spectrum of applications is possible.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

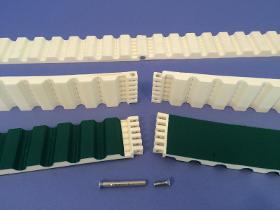

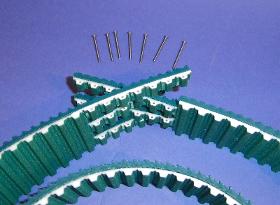

PU timing belts with easy joint as strong as a welded joint The easy joint timing belt fastener is the perfect solution, for a quick and easy mechanical endless connection of PU timing belts. Assemble without disassembling, without stopping your production line Replace your belts in few minutes without disassemble your hoods, pulleys, axis. Reduce your production downtimes. The method of mechanical assembly and fastening system easy joint offers unique solutions for easy and fast repairs of power transmission belts or conveyor belts. Pitches: H / T10 / AT10 / T20 / AT20 / 8M / 14M Standard: Polyurethane 90° Shore A grey Versions: Standard, PAZ, PAR Cords: reinforced with a Polymercord around the Pin in each tooth joint, arranged in parallel Width: from 10 to 150mm, (wide belts possible on request)

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper open-ended PU timing belts are made of abrasion-resistant polyurethane and high-strength steel cords or aramid cords and are available in open lengths. These timing belts are very suitable for synchronous conveying and positioning applications because they have very high flexibility and can be made with many different tooth shapes and materials; when combined with different tension cords, innumerable applications are possible. Keiper open-ended PU timing belts can be produced endless welded and by the meter in almost all lengths and widths. Based on this combination of high-quality materials and production methods, these belts exhibit outstanding mechanical, chemical and physical properties. Endless welded timing belts are available in any length. Welded PU timing belts primarily are used in conveying technology.

Request for a quote

NORELEM FRANCE

France

Belt back and belt teeth CR. Tension cords Glascord. Tooth covering mesh polyamide. Note Endless toothed belts with an arched profile as per ISO 13050 with metric pitch. The rounded shape of the tooth contour provides a particularly high degree of safety against incorrect tooth interlocking, combined with a very rounded tooth mesh. Operating noise is significantly reduced by the rounded tooth mesh. The toothed belts are robust, economical and versatile. Belt speed vmax perm. 50 m/s Transmissible power up to 8.42 kW Permissible speed up to 14000 rpm Lownoise and lowmaintenance Very good chemical resistance, particularly against oils, greases and fuels Accurate positioning and angles

Request for a quote

NORELEM FRANCE

France

Endless toothed belt with trapezoidal profile to DIN 7721 T1 with metric pitch. Ideal for drives with high belt flexibility. Permits smallest pulley diameters. The toothed belts are intended for drives where precision is a requirement, safety is important and the effects of chemicals are a concern. maintenancefree highpower transmission minimal belt extension accurate positioning and angles very good chemical resistance, especially to oils, greases and fuels extremely high abrasion resistance transmits power up to 30 kW reliable speed up to 10,000 rpm

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Extremultus drag belts are special developments with superior mechanical and electrostatic characteristics which make conveying and handling electronic components more efficient and safe: due to the HC or HC+ characteristics (highly conductive or highly conductive plus) the static electricity that builds up in the conveyor can be discharged better in a controlled manner; due to simplified accumulation with TT types which produce consistently low friction coefficients on the top face and underside; due to a particularly high level of abrasion resistance, as well as stable, lint-free belt edges. Siegling Extremultus drag belts are supplied endless, prepared for splicing, or as roll material.

Request for a quoteFAUDI GMBH

Germany

Advantages High flow rate Various endless-filter belts or non-woven fabric can be used Cleaning system for endless filter belts Highly economic Area of application Vacuum filters are used for the cleaning of coolants, e.g. for central filter systems with high flow rates and machining processes like turning, drilling and grinding. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid with Filtration degree 30-40 µm Medium oil and emulsion Filter material non-woven fabric

Request for a quote

KULLEN-KOTI GMBH

Germany

For this brush type we use standardised vee-belt profiles, made of polyester elastomers and immune to moisture, oil and grease as well as resistant to numerous chemicals. Therefore an application is possible in a temperature range from -15°C to +80°C. They can be produced in all lenghts requested, open ended or endless closed belt. Mainly natural hairs and bristles, plant fibres and synthetic bristles (PA, PP, etc.) are used, so all kinds of brush surface - from very soft to very hard - can be obtained according to the material quality chosen. For the endless vee-belt brushes you normally have to use a belt pre-tension of 3% of the distance between the pulleys (a). In order to obtain this we recommend that an adjustment device (such as a slot) is used with an adjustment range of 5% of the distance between the pulleys (a). You can use standardised drive pulleys to drive the belt brushes.Please ensure the diameters of the deflection pulleys are correct in order to obtain an...

Request for a quote

KULLEN-KOTI GMBH

Germany

We can produce flat-belt brushes in any length requested, open ended or endless. They are mainly equipped with natural hairs or bristles, plant fibres or synthetic bristles. Depending on the fill material a brush surface from very soft to very hard can be obtained. As belt qualities we supply the multilayered types 5,8 mm or 7,0 mm (belt thickness) with a cover sheet and running surface made of chrome leather and an integrated polyamide insert. They are suitable for temperatures from -15°C to +80°C. When using endless closed belts, belt pre-tension is an important factor.For our types 4,8 mm to 9,5 mm we normally use a belt pre-tension of 1,5 to 2% of the distance between the pulleys (a). In order to obtain this we recommend that an adjustment device (such as a slot) is used with an adjustment range of 5% of the distance between the pulleys (a). Please ensure the diameters of the deflection pulleys (d) are correct in order to obtain an adequate looping of the belt. We advise you...

Request for a quote

ERO JOINT .TANALS

France

The mechanical fastening system ERO Joint® is available on pitches T10, AT10, T20, AT20, 8M, 14M for all widths over 16mm with reinforcement Steel, Kevlar or Stainless steel. (The recommended minimum diameter for pulleys is 50mm). The ERO Joint® splice is compatible with all type of coatings (Supergrip, Linatex®, PU, Sylomer®, …) and all types of guiding. ADVANTAGES Advantages are a fast and easy installation and assembly. With the pin mechanical fastening system ERO Joint®, you will optimize your production downtime by reducing the repair time. The assembly can be realized by screwing or with a tool. This tool enables the pre-tension of belt and makes pins threading easier. ERO Joint ® Ultimate version In Ultimate version, the mechanical belt fastener ERO Joint® transmits more than 50% of the power of a Flexbelt (true endless belt): Between pulleys, there is always a ½ continuous tight side to assure the mechanical resistance and the rigidity of the belt.

Request for a quote

ERO JOINT .TANALS

France

Exclusive Gates and Tanals The only power transmission belt with mechanical assembly The mechanical fastening system ERO Joint® - developed by Tanals - provide various possibilities to assemble belts on-site without having to disassemble pulleys or axes and to release the transmission. ERO Joint® and ERO joint® Ultimate are developed for and with Gates by Tanals. They offer unique solutions system for easy and fast repair of power transmission. The cutting shapes of the junction fingers have been engineered for maximum tensile strength and fatigue resistance of the Poly Chain® GT Carbon™ material. The power of Gates combined with the creativity of Tanals. Poly Chain® GT Carbon™ outstanding mechanical performance combined to patented innovative solution ERO Joint® Ultimate offer the only transmission belt with mechanical assembly whose performances equal those of all other endless belts on the market. A sustainable solution able to replace any rubber belt.

Request for a quote

ALLIED FOR TECH

Poland

We perform grinding mainly on endless belts, as well as with the use of special grinders and hand-held power tools.

Request for a quoteResults for

Endless belt - Import exportNumber of results

35 ProductsCompany type