- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electrical press

Results for

Electrical press - Import export

SC BELFORM PROD SRL

Romania

The equipment offers the hydromassage function, through pneumatic control. Starting and stopping the electric pump is done by pressing the pneumatic button. Adjusting the air flow taken by the water jets is done by turning the regulator or regulators (two for larger tubs). Structure: 6 - 8 adjustable and adjustable water-air hydromassage jets (depending on the size and geometry of the bathtub) 700W electric pump – production in Italy or Spain Sorb Automatic column with siphon Metal support with adjustable legs and wall fixing brackets , anti-corrosive protection Manual control

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

DEKORTECH GMBH

Germany

Electric heat press for textile transfers. ✔ Singe platen ✔ Even temperature and pressure ✔ Opens and closes automatically ✔ 30 x 40cm base plate ✔ No compressor ✔ Pull out base plate This neat looking heat press is great for small businesses and DIY. The fully electric heat press is designed for small quantities. Due to its electric closing mechanism, it is easy to operate without exhausting your arm. Using a small display, you can adjust temperature and dwell time to your likings and save pre-sets for reoccurring applications. In automatic mode, a small sensor closes the press once the base plate is pushed in all the way. This press can be used for t-shirts, hoodies, bags, sleeves, legs, bags, neck tags and a lot more. Works perfectly with all kinds of transfers from DTF to screen printed or vinyl.

Request for a quote

FORBO SIEGLING GMBH

Germany

The Siegling Blizzard HC is a new benchmark in quality and speed when heating splices for Siegling Extremultus belts in the aramide and polyester lines as well as narrow Siegling Transilon belts. It’s easy to handle and has very short cycles. Automatic heating and cooling in one single tool prevents mistakes made during handling saves having to put the belts and splicing guide into a cooling clamp after heating is highly efficient due to short cycles delivers excellent splicing results with superior repeat accuracy

Request for a quote

DEKORTECH GMBH

Germany

Electric double heat press for textile transfers. ✔ Double platen ✔ Even temperature and pressure ✔ Opens and closes automatically ✔ Up to 40x50cm base plate ✔ No compressor ✔ Laser guides This fully electric double heat press is designed for medium size productions without compressed air. Due to its electric closing mechanism, it is easy to operate without exhausting your arm. And while one side is pressing, you have time to prepare the other for the next cycle. Furthermore, a small gap underneath the base plate allows you to thread the t-shirt onto the platen. Using a small display, you can adjust temperature and dwell time to your likings. In automatic mode, the machine will automatically close and open the press as well as move it from one platen to the other based on set timings. With a range of different base platens, this press can be used for t-shirts, hoodies, bags, sleeves, legs, bags, neck tags and a lot more.

Request for a quote

FORBO SIEGLING GMBH

Germany

The Siegling Blizzard press is supplied with a flight case on castors. Because it’s so compact and lightweight, it’s quick and easy to set up. It’s ready to use as soon as you’ve plugged it into the mains because there’s no need to connect it to external subsystems. The control unit, compressor and air cooling system are integrated in the press. This saves time and costs, prevents errors during operation and ensures hygiene on site.

Request for a quote

FERPLAST SNC

Italy

CODE MARKER FPHP 280- Recommended for medium-high productions. Thermal marker hot ink ribbon, ideal for marking labels and cartons. Operation: The operator must enter the letters in the type holder, turn on the marker and set the temperature suitable for the operation. The variation of working temperature depends on thickness and typology of product to be marked. The marking can be done when the marker has reached the temperature. Marking with FPHP 280 marker: The operator must enter the letters in the type holder. Pressing the electric pedal, the marker makes marking quickly (in about 2 seconds). It's a recommended marker to print expiration dates or lots. It's an electric model, then the printing quality is very good and does not vary from time to time because the descent of the characters happens in a vertical manner and the pressure is always constant. The head with the letters transfers ink from the ink ribbon to the product creating a permanent and lightly engraved marking.

Request for a quote

FERPLAST SNC

Italy

Semiautomatic table top sealer with electric pedal and impulse sealing bar (resistance is heated for a few seconds), suitable for closing bags of plastic material heat-sealable. The closing of the sealing bars by pressing the pedal electric with solenoid allows the operator to have both hands free and for increased production, just select the automatic cycle with timed closure. The timers for adjusting the welding and cooling ensure maximum reliability of each type of material. Simple to use, requires no preheating. Maximum thickness. weldable 0.20 mm. (0.40 mm. Overall)

Request for a quote

FERPLAST SNC

Italy

Semiautomatic table top version or with pedestal sealing machine with electrical pedal and double sealing impulse bar, (resistance to heat for a few seconds), suitable for closing envelopes polyethylene, polypropylene, PVC, coupled in aluminum, etc. The closing of the sealing bars by pressing the electric pedal with solenoid allows the operator to have both hands free. The timers for adjusting the sealing and cooling ensure maximum reliability of each type of material. Simple to use, requires no preheating. The double sealing bar (above and below) and the sealing of 5 mm. allows the closing of envelopes with thick, laminated bags and bellows. Through a selector switch, you can choose whether to use one or two sealing bars. Maximum solderable thickness 0.25 mm. (0.50 mm. overall). It's also available the model ME 6010 FDA / FDV with 600 mm sealing bars and 10 mm welding.

Request for a quote

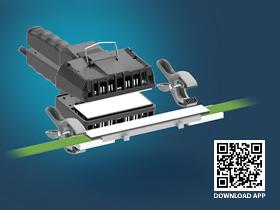

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The Z+F EVOPRESS is an electrically driven crimping press for processing a wide variety of electrical connectors such as Z+F ferrules and Z+F terminals. With its compact design it fits into the Z+F EVOLINE. Crimping Machines, such as the Z+F EVOPRESS, are electrically powered tools specialized in the precise processing of various electrical connections. These machines are particularly utilized in handling electrical components like Z+F ferrules and Z+F cable lugs. Their primary function involves establishing a secure and durable connection between electrical conductors and their corresponding terminals through the application of pressure. The Z+F EVOPRESS and similar crimping machines not only deliver high performance but also provide the capability to process various types of electrical connectors with precision and efficiency. Key Features of the Z+F EVOPRESS: Enhanced hand safety with a protective glass at the front of the machine

Request for a quote

REP INTERNATIONAL

France

Electric horizontal machine, ultra compact for an optimized productivity! Suitable for the injection of many elastomers (rubber, silicones, etc.) Compact & ergonomic 33% smaller footprint compared to other presses on the market All features and production capacity in less than 4 meters length Productive & electric powered performance Productivity +20% 60% reduction in injection time 30% decrease in cure time Sustainable & Ecofriendly 50% power consumption 100% Water consumption 14% Waste reduction Oil free The “SmartWire” technology allows production to become autonomous and connected.

Request for a quote

REP INTERNATIONAL

France

THP range machines are particularly appropriate for the molding of oil seals, backup rings, parts for the automotive industry and many other rubber parts. There are two series, 2RT or 3RT, depending on the number of mold platens. Of simple design for easy maintenance, they can be provided as single or double station machine. Their vacuum cover design allows for reduced curing time and therefore increased profitability. The top platen, which is inclined by 60°, is suitable for different demolding options.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Detecting mechanical faults before they stop production Bearing and Machine Maintenance Industry runs on machinery. Bearings, pumps, electric motors, compressors, presses, gearboxes and much more. All of which can break unexpectedly, causing production to stop. When production stops your organization loses money. Few bearings make it to the end of their engineered lifecycle. This is due to poor workmanship, bad lubrication practices and neglect. Problems can even arise right after installation due poor installment of the machine. No two machines are the same. Across industry, machines operate under different loads, climates and conditions, making their maintenance requirements unpredictable. Many machines are still maintained on calendar based PM’s, while others are run-to-failure. Both strategies are wasteful.

Request for a quote

PIR.SA.FA. S.R.L.

Italy

Our Company produces 100 mm coffee stirrers and 110 mm cappuccino stirrers, bulk packaged in bags. The materials used (food-grade and compliant with the MOCA regulation concerning Food Contact Materials) are: PS or PLA, in white or coloured version (food-grade pigments compliant with the MOCA regulation concerning Food Contact Materials). Each of the packaged bags are electrically welded: total absence of glue. The machines and equipment used for the production of highly innovative stirrers (moulds treated to avoid the use of lubricants and without plastic waste; electrical injection presses without hydraulic oil and with low energy consumption) together with highly qualified personnel for accurate control of production, ensure high standards of quality, safety and hygiene of products in compliance with current industry legislation.

Request for a quote

ANDRITZ KAISER GMBH

Germany

The production of electric motor and generator laminations imposes strict requirements on the press and automation. ANDRITZ Kaiser looks back on decades of experience in the electric motor laminations sector and provides the customer with state-of-the-art solutions. Precise timing and general performance are required for competitive productivity of high speed stamping systems for laminations. Due to the large amount of cutting operations required, a very rigid machine is needed to absorb the cutting impact without damaging any machine part. Finally, the tolerances of 0,02mm in the tools and the end product call for a very precise slide movement, slide guideance and low frame deformation. Our well designed and thoroughly tested concept allows customers to manufacture high-quality products with maximum efficiency. ANDRITZ Kaiser production lines for electric motor laminations are characterized by the following features: Highly stable machine with split-design, cast iron frame for...

Request for a quote

LVD

Belgium

The Strippit E Series servo-electric punch press is energy efficient, economical to operate, and offers precise control over the ram for consistently accurate forming operations. The electric press drive system uses fewer mechanical components, keeping machine reliability and uptime high, and maintenance costs to a minimum. A 47-station turret features three 88,9 mm auto-indexable stations for tremendous tool-carrying capacity and flexibility. KEY FEATURES Servo-electric press drive – average power requirement of 20 kVA Large capacity 47-station thick turret Three programmable 88,9 mm auto index stations Indexable multi-tool capability offers more capacity Quick-change die holders Smart Clamp ensures the smallest possible no-punch zones 25 mm feed clearance for more forming capacity Efficiently handles thicker materials with 20 metric tons of punching force Integrated Touch-P control is intuitive and simple to use PERFORMANCE-ENHANCING OPTIONS CADMAN-P programming software

Request for a quote

LVD

Belgium

The Dyna-Cell features the high-speed Dyna-Press Pro electric press brake coupled with an industrial robot. The compact, integrated unit automates the bending of small- to medium-sized parts in varying batch sizes at speeds of up to 25 mm per seconds. Dyna-Cell offers maximum bending productivity in a compact footprint of 5 m x 5 m. KEY FEATURES Optimum cost-benefit ratio Fast, electric-drive press brake Lightweight Kuka industrial robot Start final production after <10 minutes CAM and <10 minutes setup Unique gripper that fits all part sizes from 30 mm x 100 mm up to 350 mm x 500 mm Space for two input pallets, two unloading pallets or boxes (Euro pallet size) Intuitive 15” Touch-B touch screen control Fully integrated with LVD's CADMAN® software suite Unmanned or manned operation PERFORMANCE-ENHANCING OPTIONS Easy-Form® Laser system CADMAN-B programming software W-style or universal tooling MODELS

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERDEMLER COOLING COMPANY

Turkey

Leakage tests of outdoor unit are performed by pressing nitrogen. Electrical panel and all automatic control elements are shipped as ready for assembly. It is manufactured in accordance with European Union norms and CE certificate. It is manufactured in accordance with hot gas or electric defrosting device. Electrostatic paint is applied on a galvanized sheet according to device size from 2 mm thickness to 4 mm thickness. Easy installation and maintenance opportunity. European equipment. Silent fan option. Minimum noise level.

Request for a quote

LVD

Belgium

The Dyna-Press is your perfect bending partner. The electric drive Dyna-Press delivers fast bending speeds of 25 mm per second to bend more parts per hour at a lower cost per part. Ideal for bending small and simple parts, its ergonomic design permits use in a standing or seated position. Add to this impressive production capabilities, easy to use control and compact size for a press brake that is fast, accurate and flexible. KEY FEATURES Compact design uses minimal floor space Easy transport with a standard forklift (except 40/15) Intuitive touch screen control Touch-B High repeat accuracy with 4-axis back gauge, 5-axis on Pro model PERFORMANCE-ENHANCING OPTIONS Extra gauge finger Safety sytem Air conditioning unit for electrical enclosure Vertical W-style or universal tooling CADMAN-B programming software MODELS Dyna-Press 24/12 Dyna-Press 40/15 Dyna-Press 40/15 Pro

Request for a quote

ERDEMLER COOLING COMPANY

Turkey

Central cooling systems are designed units to use for the removing of thermal loads which are pointed at more than one cooling point. The system will have the appropriate capacity depending on the desired power designed in the same or different capacities of compressors. Electric power supply and control panel are on the unit, and all connections are made in the factory. Scrolling, hermetic, semihermetic varieties of central system are available. Semihermetic or screw compressors are used in the central system for the center of industrial plants with high cooling capacity. Hermetic and scroll compressors are used to lower capacity the projects. Leakage tests of outdoor unit are performed by pressing nitrogen. Electrical panel and all automatic control elements are shipped as ready for assembly. It is manufactured in accordance with European Union norms and CE certificate.

Request for a quote

ERDEMLER COOLING COMPANY

Turkey

The shocking devices are compatible with the projects which should be kept in the warehouse required to be transformed into a frozen enclosure as soon as possible. The screwed and double stage compressors are used in the shocking devices. Its evaporator is also special type. In order to make it into a frozen enclosure without blowing directly, there are directors on the product. Leakage tests of outdoor unit are performed by pressing nitrogen. Electrical panel and all automatic control elements are shipped as ready for assembly. It is manufactured in accordance with European Union norms and CE certificate. It is manufactured in accordance with hot gas or electric defrosting device. Electrostatic paint is applied on a galvanized sheet according to device size from 2 mm thickness to 4 mm thickness. Easy installation and maintenance opportunity. European equipment. Cooling capacities 35/40.

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Wet electric lters are required where high demands are made on the levels of separation of aerosols, ne dusts and so on. Wet electric lters may be synergistically integrated into Siempelkamp's press extraction systems. Features Optimum performance through integration of the wet electric lters into the press extraction systems Water-circulation system for press extraction systems and wet electric lters Advantages Lower investment costs through integration High aerosol-separation levels (blue haze) High dust-separation levels Options Unscrubbed gas volume ows from 70000 Bm³/h to 150000 Bm³/h* *) Bm³ = cubic metre at operating pressure

Request for a quoteResults for

Electrical press - Import exportNumber of results

23 ProductsCompany type

Category

- Cooling and lubrication pumps (4)

- Brakes, servo-brakes and accessories (2)

- Mechanical transmission - components (2)

- Package sealing machinery (2)

- Silk-screen printing (2)

- 3D scanner (1)

- Bathroom accessories (1)

- Heat transfer printing (1)

- Laser - cutting and welding machines (1)

- Metal industrial presses (1)

- Plastic products for the garment industry (1)

- Scientific and technical monitoring (1)

- Wood veneer - machinery and equipment (1)