- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dust separators

Results for

Dust separators - Import export

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

Vshaped arranged filter plates from closely pleated 4layer filter media composite nonwoven from electrically uncharged, organic, synthetic microfibres and activated carbon grains rugged KALTHOFF filter casing of plastic doubleworking arrester very high adsorption kinetics conditions for mounting and service optional at site

Request for a quote

ROBINSON CO.

Turkey

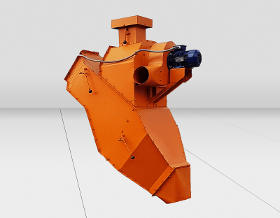

It is generally used as a dust collector, dust and air separator for the product. It is found in aspiration systems of cleaning machines. Dust removed by aspiration is separated from the air by means of a cyclone. The dust-laden carrier air is directed inside the separator thanks to the helical construction and is forced to rotate in the cyclone. Dust particles are dispersed to the environment with the effect of centrifugal forces arising due to rotation. Dust particles are carried along a helix path by means of the vortex created by the air pushed from behind. The clean air separated from the dusts goes through the suction pipe and goes to the outlet. Dust particles are directed downwards along the spiral due to the friction of the air against the wall. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

Pellet sieves, take the oath pelletized powder pellet press again sends to the upper reservoir. pellet separated from the dust, Sent to the finished product silos. Depending on the space 2 or 3 cassette and 2 or 3 It is produced as output. Manufacturing is done in two separate models; vibrating screen and rotary screen. the centrifugal force will occur due to vibration and shaking vibration body vibration minimizing the special chassis system for dust separation, characterized in pellet diameter kullanılmaktadır.h. Dust sealing özelliği.kolay be changed 2 or 3 There ply sieve tray system. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quote

PARSMEGA MAKINA

Turkey

Hulling machine is used to peel wheat. Separates foreign substances such as dust, sand and small seeds in wheat. It crumbles the soil and other adherent grains attached to the wheat grains, reduces the bacterial load, protects the wheat from bacteria and insects. Ours. It also enables the separation of grains that have not been separated from the spike. Wheat entering the machine from the wheat inlet section directly enters the wheat peeling section. Here, the wheat is husked by the rotation of the steel rotor, and the clean, hulled wheat is directed to the outlet thanks to the pallets on the rotor. The husks and dust separated from the wheat are thrown out of the machine with air through the holes of the steel braided wire on the rotor.

Request for a quote

PARSMEGA MAKINA

Turkey

This type of filters are used to separate dust particles from dust-laden air, they can be used with positive or negative pressure, the filter bag is cleaned by 0.5 bar pressurized clean air that does not contain oil and water.

Request for a quote

SEMIN

France

TECHNICAL DEFINITION Ready-to-use coating paste for smoothing irregular surfaces on interior and exterior walls. Particularly suitable for damp areas. COMPOSITION AND APPEARANCE Emulsion resin, calcium carbonate, water, rheological agent and various additives. The paste is off-white in colour. SUITABLE SURFACES • Plasterboard panels • Plaster blocks • Ceramic tiles • Concrete • Cement coating • Rpe • Old paint • Glass web fabric • Sanded and printed wood SUITABLE SURFACES Plaster-based top coat. Paste coating. Matte paint. TECHNICAL CHARACTERISTICS • Granulometry : up to 0.6 mm • Adherence : complies with NFT 30 608 • pH : neutral • Dry extract : 80% STORAGE 6 months in unopened original packaging, away from frost and extreme heat. CLASSIFICATION AFNOR NFT 36.005. FAMILY IV - CLASS 4 B. COMPLIES WITH DTU 42.1. PREPARATION OF SURFACES Surfaces must comply with standard DTU 59.1, and be clean, dry and free from dust and any trace of separating agent.

Request for a quote

SEMIN

France

COMPOSITION AND APPEARANCE Plaster-based powder filler, special cements, calcium carbonate, resin, cellulose fibre and various admixtures. The compound obtained is white in colour. TECHNICAL CHARACTERISTICS • Setting time : 30 to 40 minutes • Hardening time : 1 to 2 hours. • Second coating : after 3 hours • Adherence : complies with NFT 30 608 SUITABLE SURFACES All types of interior surfaces complies with DTU 59.1 : plaster, plasterboard, plaster blocks, concrete, cement coating, breeze blocks, cellular concrete, bricks, ceramic, old paintwork, old painted fibreglass, floor tiles, wall tiles, etc. COVERINGS After the filler has completely dried, it can be covered using all types of paints, plaster-based coatings, paste coatings, wallpaper paste. PREPARATION OF SURFACES Surfaces must comply with standard DTU 59.1 and be clean, dry and free from dust and any trace of separating agent. Correctly open up, bevel and dust off the cracks.

Request for a quote

R&S PAPIERVERARBEITUNGS-GMBH

Germany

The synthesis dust filter bag has been a very high quality option for commercial cleaning for more than 10 years. The non-woven material is very robust, so that e.g. stones, light moisture and fine dust can be absorbed. In addition, dust retention values, separation efficiencies and durability have been improved. For these reasons, the Synthese dust filter bag is also increasingly used for light cleaning jobs. Synthese 3, 4 or 5 ply, filter bags with dirt flap, sliding closure or plastic connection, Synthese dust filter bags also in set with motor protection filter, household filter bags

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Strip brush cowls are used to stop either dust escaping or for product separation. They can be manufactured in any Overall diameter and most filament diameters. Call us to discuss any types of cowl that your machinery needs.

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

The supersonic filter is used for the separation of air-dust mixtures coming from the aspiration system as well as pneumatic conveying systems. The air-dust mixture enters the machine and the dust remains on the filter bags. These filter bags are shaken out using pressurized air by the diaphragm system and the dust is collected at the bottom of the filter. For the removal of the dust collected at the bottom of the machine, a sweeper can be used as well as a conical bottom with a rotoflow.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Instead of a dust separator and a pneumatic conveyor, a cyclone is installed on a self-moving OBC-25CB grain cleaner, and a hopper instead of scraper feeders. The volume of the hopper of the OBC-25CB grain cleaning machine is about 1 cubic meter. OBC-25CB grain cleaner cyclone collectsdust, straw and light impurities. As a result, personnel can work without respirators and dust does not settle on already cleaned grain, people and equipment. The hopper of the OBC-25CB grain cleaning machine allows the grain truck to unload grain directly into the hopper, and not onto the floor. As a result, grain trauma, energy consumption and wear of the OBC-25CB loading conveyor are reduced. You can also load grain into the OBC-25CB hopper with a screw, noriya, loader, etc. Grain cleaning in OBC-25CB is carried out by adjustable air flow and sieves, which allows to obtain high quality cleaning. You can also purchase an OBC-25CB grain cleaner with a hopper and scraper feeders.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The AS-60 air separator is used when cleaning grain to separate dust and light fractions from the grain. It can be used for different types of cereals, for example, for wheat, durum wheat, corn, rye, soy, oats, buckwheat, millet, rape, rice, as well as for sunflower, peas, chickpeas, beans, cocoa beans, etc. Cleaning grain from dust and light impurities ensures its long-term storage and helps to prevent various potential threats. Due to the unique design of the cascade type, the AS-60 air separator provides high quality cleaning of grain from dust and light impurities. Air speed and grain feed are very easy to adjust with 3 handles. This allows you to adjust the separation settings at any time depending on the properties of the grain being cleaned. Due to its simple, effective design and wide adjustment range, the AS-60 air separator has many applications. This separator can be used separately, installed in stationary grain cleaning lines or used as part of mobile grain cleaner.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to centrifugally separate dust - air mixture and generally is designed as a dust receiver in pneumatic conveying systems

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For the conveying of filtered-out materials to silos or containers. Pneumatic low-pressure conveyor systems For the conveying of filtered-out materials to silos or containers and for conveying distances of up to 200 m. The conveying air stream is generated by one or more fans. Product description Pneumatic low-pressure conveyor systems can be implemented as a single-pipe system or a ring system. In the case of the single-pipe system, a final separator in the form of a filter or a cyclone is always necessary. In a ring system the conveying air is driven in the ring. In this case the silo or container acts as the separator. Light dust particles that are not separated in the silo or container initially remain in the circulation. With most materials the fine dust particles tend to attach themselves to the coarser ones and are thus separated with them. Hence, a concentration of the fine dust particles in the conveying stream is avoided as far as possible. The loading of the conveying stream essentially depends on the grain size, density and form of the material to be conveyed. As a guiding value, one may assume 250 - 300 g/m³. Higher loads are possible under certain conditions. In cases where there is a high amount of material, e.g. in planing works, where the splinters are directly removed and transported away for further use, this can also be realised with a ring system and several containers. Switchover takes place automatically when the container signals that it is full. Containers are exchanged during operation.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Force-of-gravity separators, which are used as pre-filters or for the separation of large quantities of dust and swarf. Cyclone separator Cyclones are force-of-gravity separators. The separation principle is based on centrifugal force, which is produced by the tangential injection of the raw air. Cyclones are used as pre-filters or for the separation of large quantities of dust and swarf. The degree of separation of a cyclone is not normally sufficient to meet the usual environmental protection requirements. The cyclone exhaust air must be post-filtered in most cases. Product description A cyclone essentially consists of three parts: the intake cylinder, the cone and the immersion tube. In the intake cylinder, the raw air is brought into a circular path by means of tangential injection. Due to the taper of the subsequent cone, the speed of rotation increases sharply, so that the particles are pressed by centrifugal force against the outer wall and decelerated by friction, causing them to drop out of the air stream and fall down. The cleaned air leaves the cone in an upward direction via the central immersion tube. Cyclones are usually welded sheet steel structures. Cellular wheel sluices or, in individual cases, double-gate sluices are used for the pressureless discharge of the material. In order to increase the cyclone effect, or the degree of separation, counter-spirals with a pipe connection can be placed on top of the immersion tube. Further options are, for example, wearing devices, explosion pressure relief devices, control flaps, level monitoring devices and manufacturing in stainless steel or galvanised sheet steel.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Type RK/RF for continuous operation, suitable for virtually all types of dust. Round filter type RK / RF The round filters from this series are suitable for continuous operation and for almost all types of dust. What is special about them is the rotary cleaning device, which causes the dust to be sucked out of the filter hoses and discharged. Using other methods the dust is also continuously dislodged from the filter element, but contaminates the other filter elements in the next moment. Only a small part of the dislodged dust falls down and is discharged. The lower part of the filter is implemented like a cyclone and acts as a pre-filter, where coarse dust is already separated and discharged. Compressed air impulse cleaning is also possible as an option here. The filtering direction of the filter hoses is from the outside inwards. The hoses are provided with support frames.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Separation of paint powder from powder coating booths. Options: Rippert powder filter This type of filter is particularly suitable for the separation of paint powder from powder coating booths and is also often used together with an upstream Rippert cyclone for powder recovery. Separation chamber with dust collecting container, filter cartridges, compressed air cleaning and sound-insulated fan are housed in a compact design. The filter cartridges are arranged vertically in order to ensure optimum cleaning behaviour and energy-efficient operation. The fan, which also comes from our own production, is characterised by smooth running and high efficiency. Standard advantages:

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WESSEL-UMWELTTECHNIK GMBH

Germany

The BIOCATDUOscrubber from WesselUmwelttechnik consists of two units. One unit is the already mentioned BIOCATscrubber. A second unit, the DLP (Dust Low Pressure) scrubber stage, is a cleaning stage for separating dust and fine fibres from the exhaust air. With the BIOCATDUOscrubbers from Wessel, gaseous pollutants as well as dust can be removed from the exhaust air at the same time. The BIOCATDUOscrubbers have two separate washing water circuits for this purpose. It is characterised by a compact design, as both units are housed in one column. COMMON USE CASES The BIOCATDUOscrubbers are used in the woodbased panels industry, for example. More precisely where MDF boards (medium density fibre) and moulded fibre parts are produced. Here the exhaust air contains fine wood fibres which have to be filtered out of the exhaust air. Furthermore, pollutants and odours must also be reduced.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

HELIO®Clean 2 is a combined conveying-/ mixing-/ and dedusting device for virgin material and regrind. The dust is removed through a 2-stage dedusting system. The compact design makes it ideal for mounting on the feed zone of the processing machine or on a drying container. The separated dust content is sucked out into an external collection bin. Available in 1- or 2-component version, filling is carried out by the integrated compressed air conveying technology with Venturi suction lance(s). Quality: Dust in granules causes lowered mechanical properties of technical plastic resins, leads to problems with surface finish in case of transparent parts, to high rate of rejects basing on smudges or white/black dots in transparent injection moulding parts like for example optical lenses of PC and PMMA. Professional cleaning of resins brings the quality to the original state again and optically perfect parts can be produced.

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Wet electric lters are required where high demands are made on the levels of separation of aerosols, ne dusts and so on. Wet electric lters may be synergistically integrated into Siempelkamp's press extraction systems. Features Optimum performance through integration of the wet electric lters into the press extraction systems Water-circulation system for press extraction systems and wet electric lters Advantages Lower investment costs through integration High aerosol-separation levels (blue haze) High dust-separation levels Options Unscrubbed gas volume ows from 70000 Bm³/h to 150000 Bm³/h* *) Bm³ = cubic metre at operating pressure

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

ZPZ – VPZ 240°C-Filterelemente (Finalfilter) for cellular gas filters: ZPZ 25 – ZPZ 50 – ZPZ 80 – ZPZ 100 – ZPZ 150, type FFX Efficiency: 99,9 > 1µm In the area of fine dust separation, the gas is cleaned with filter cartridges. Our filter cartridges are all tested according to ISO 12103-01 and proven to be efficient, according to the requirements of the internationally valid “Test Aerosol: SAE-Fine Test Dust”. For special fields of application we can offer and develop special filter elements in order to achieve a performance-fulfilling filtration.

Request for a quote

APER DIAMOND SL

Spain

THE ESSENTIAL MODEL WHEN YOU HAVE TO POLISH LARGE SURFACES. THANKS TO RADIO CONTROL, HANDLING IS GREATLY SIMPLIFIED, AND MORE WORK IS DONE PER DAY. IN ADDITION, THE WORK IS MORE EFFECTIVE, SINCE THE EMPTYING OF THE DUST SEPARATORS AND THE HANDLING OF THE CABLES CAN BE DONE WHILE THE MACHINE IS CONTROLLED REMOTELY. ANOTHER ADVANTAGE IS THAT THE TRANSPORT, CHARGING AND UNLOADING OPERATIONS OF THE MACHINE ARE MORE COMFORTABLE THANKS TO THE BATTERY.

Request for a quote

APER DIAMOND SL

Spain

AIRFLOW INDICATOR. INDICATES WHEN IT IS TIME TO CLEAN OR CHANGE THE FILTERS ON YOUR EQUIPMENT HRATED EQUIPMENT FOR ADDED SAFETY. THE EQUIPMENT COMPLIES WITH THE HIGHEST INTERNATIONAL "H" STANDARD (IEC60335269, EN60335269). EFFECTIVE CLEANING OF THE FILTER. EASY CLEANING OF THE PRIMARY FILTER TO KEEP AIRFLOW HIGH. 3STEP FILTRATION. THE DUST EXTRACTOR EFFECTIVELY SEPARATES THE DUST INTO THREE STEPS WITH A TURNING DEVICE, PRIMARY FILTER AND HEPA H13 FILTER. LONGOPAC® SYSTEM. IT ALLOWS YOU TO HANDLE DUST EASILY AND SAFELY IN LONGOPAC® COLLECTION BAGS.

Request for a quote

TOPPY PACKAGING

Italy

Master toppy can process up to 18-20 pallets per hour in optimal conditions. The Air Jogger allows for dust removal, separation and alignment of the sheets. This machine guarantees increased safety and productivity. The operator wil select the cycle and monitor the turning and processing of the pile effortlessly.

Request for a quote

TOPPY PACKAGING

Italy

This version of Master Toppy can effortlessly be managed by the operator from the control panel. The air jogger allows for sheet separation , alignment and dust removal.

Request for a quote

FORVAC SERVICES LTD

United Kingdom

Forvac is the proud manufacturer of our own British designed and built heavy duty FVP & FV electric, diesel, fixed or portable industrial vacuum range. Having our own design and development team we also, manufacture bespoke industrial vacuums and systems providing complete tailored solutions, designed to suit the application and customer requirements. After the initial on-site consultation, our design team and project manager will determine and provide, the most cost effective solution for the application, whether it be a standard or bespoke. Forvac designs, builds and installs from start to finish, using our own design team and installation engineers, ensuring costs are kept to a minimum. The savings don’t stop there, Forvac is also the distributor for Lajac pipework ducting systems, keeping our prices even more competitive. Whether it’s supplying a new machine, a new or modified ducting installation or a complete system, we would be more than happy to help.

Request for a quote

BALKAN MOTOR SANAYI VE TICARET A.S.

Turkey

The Superior Technopolish Polishing Machine which is quipped with the highest quality materials and the latest technology, runnings at two speeds as 1500 and 3000. Thanks to its ergonomic design, it is compatible with all kinds of working conditions. It has an arm support that provided to you work tirelessly. Thanks to the buttons it is easy to use and trouble-free. Ergonomic design. Maintenance-free, quiet and high-performance powerful motor. Water resistant 304 quality stainless steel body. 750 m3 Vacuum with superior suction power. 3 filtration System which has fine dust separation and easy to clean. 4X9 1600 lm Daylight Led Lighting. Movable transparent plexiglass protector.

Request for a quote

BALKAN MOTOR SANAYI VE TICARET A.S.

Turkey

The newest touch-screen product Smart Polishing Bench. While designing this product, we have keep in mind our customers who prefer the entire convenience of a polishig bench and maximise their satisfaction. This Exceptional Polishing Bench which is equipped with the highest quality materials and the latest technology, gives you the flexibility to work at any speed between 300 and 3000 rpm. Exceptional touch screen. There are no any switches. Exceptionally easy operation, precise speed adjustment and display. All settings will be made via high-tech touch screen. Maintenance-free, quiet and high-performance powerful motor. Water resistant 304 quality stainless steel body. 750 m3 Vacuum with superior suction power. 3 filtration System which has fine dust separation and easy to clean. 4X9 1600 lm Daylight Led Lighting. Movable transparent plexiglass protector.

Request for a quoteResults for

Dust separators - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Flour milling - machinery and equipment (3)

- Vacuum cleaners - industrial (3)

- Agriculture - Machines & Equipment (2)

- Jeweller's, watchmaker's, gold- and silversmith's machinery and equipment (2)

- Jewellery (2)

- Oils, cooking - machinery and equipment (2)

- Additives, cement and mortar (1)

- Air purification - equipment and systems (1)

- Cardboard and cardboard products - processing machinery (1)

- Cement and additives (1)

- Filtering equipment and supplies (1)

- Finishing and binding - machinery and equipment (1)

- Food canning and preserving - machinery and equipment (1)

- Metal brushes (1)

- Paper - Printing - Machines & Equipment (1)

- Plaster and plaster products (1)

- Plastics - industrial machinery and equipment (1)

- Pneumatic conveyor equipment (1)

- Sand and gravel (1)

- Wood veneer - machinery and equipment (1)