- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drive elements

Results for

Drive elements - Import export

PGR DRIVE TECHNOLOGIES

Turkey

The most important feature of the PCD series, which has a different design from traditional gearboxes, is that the drive elements transmit the movement by rolling over each other, instead of the friction movement of the gears with each other as in normal gears.

Request for a quote

IGUS® GMBH

Germany

News 2014 Lubrication-free drylin® screw drives: larger and high resilience, new sizes and many more… All News and line extensions Application examples Be inspired by our lead screw unit application examples. drylin® lead screw units - application examples 3D-CAD Faster and simpler designing with file formats for various systems. 3D-CAD Online-Shop Inform, select and order online. Information about drylin® screw drives, quick selection and order. Delivery in 24 h or today* DryLin® screw drives Find them quick with selection aids The product finder and the service life calculation offer you the possibility to find the suitable drylin® screw drives quickly. Product finder and lifetime calculation for screw drives Special dimensions Configurator for leadscrew nuts and -spindles for special dimensions. Screw drives special dimensions Classic format adjustments and lifting applications can be implemented with the self-locking trapezoidal thread. Quick adjustments or handling utilize the high ratio of the steep thread. In addition to steel, all spindles are available in stainless steel and thus provide a corrosion-resistant solution in combination with drylin® threaded nuts made of iglidur® plastics. Advantages: Maintenance-free, dry operation Low noise Insensitive to dirt and dust XYZKorrosionsfrei Trapezoidal thread and high helix thread High efficiency Anti-backlash function available FDA certification available Screw drives are machine elements that convert a rotary motion into a translational motion. drylin® screw drives are always based on self- lubricating plastic nuts and thus enable a life-long operation without external lubrication. The spindle (trapezoidal thread or steep thread) remains in dry operation, providing many technical advantages. For example, dirt does not stick to lubricants. The screw drive can thus be used on the one hand in applications with extreme dirt accumulation and on the other in the hygiene sector. Different thread types cover a wide range of applications. drylin® - Trapezoidal leadscrew nut - Technical data Classic format adjustments and lifting applications can be implemented with the self-locking trapezoidal thread. Quick adjustments or handling utilize the high ratio of the steep thread. In addition to steel, all spindles are available in stainless steel and thus provide a corrosion-resistant solution in combination with drylin® threaded nuts made of iglidur® plastics. Advantages: Maintenance-free, dry operation Low noise Insensitive to dirt and dust XYZKorrosionsfrei Trapezoidal thread and high helix thread High efficiency Anti-backlash function available FDA certification available drylin® screw drives: Efficiency measurement News 2014 Lubrication-free drylin® screw drives: larger and high resilience, new sizes and many more… All News and line extensions Application examples Be inspired by our lead screw unit application examples. drylin® lead screw units - application examples 3D-CAD Faster and simpler designing with file formats for various systems. 3D-CAD Online-Shop Inform, select and order online. Information about drylin® screw drives, quick selection and order. Delivery in 24 h or today* DryLin® screw drives Find them quick with selection aids The product finder and the service life calculation offer you the possibility to find the suitable drylin® screw drives quickly. Product finder and lifetime calculation for screw drives Special dimensions Configurator for leadscrew nuts and -spindles for special dimensions. Screw drives special dimensions

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special cases.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special cases.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Round belts are used for conveying in the textile, wood-working, ceramic, packaging and chemical industries.Siegling Transilon round belts serve as efficient drive elements in both precision tool and machinery manufacturing. Siegling Round belts have also proven their reliability as drive elements for live roller conveyor repeatedly. Their great flexibility and elasticity make any turn possible.

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

ARCUSAFLEX ® + electromagnetic clutch \ AC+EMC ➜ Suitable for torque transmission with an initial differential speed between the drive elements ➜ High torques in the smallest of installation spaces ➜ Designs up to 8 200 Nm, others on request ➜ Quick decoupling without residual torque ➜ Maintenance-free ➜ Suitable for a variety of applications ➜ Emergency operation possible ➜ 24V DC operation, other variants possible ➜ De-energised when open

Request for a quote

FORBO SIEGLING GMBH

Germany

Textile Industry For decades Forbo Movement Systems has been accompanying the numerous developments in the manufacture of yarn and fabrics together with the textile machine manufacturers. The results are: Power transmission belts with thermoplastic tension members made of polyester and aramide as drive elements in yarn processing Cross-lapper belts with specially developed coatings New printing blankets for ideal printing results

Request for a quote

BVS ELECTRONICS GMBH

Germany

Lenze drive technology Regardless of whether you require motors, gear units or specific drive elements, we have an extensive selection of products manufactured by Lenze to meet your exact requirements. This includes frequency converters and servo motors as well as various accessories, such as signal and power cables, function modules, handheld terminals and mounting kits. We not only complete repairs for products manufactured by Lenze but also sell and service these modules.

Request for a quote

LUTZ PUMPEN GMBH

Germany

Suitable for neutral and aggressive liquids as well as liquids containing solids Application: Centrifugal pump for dry-well installation featuring a bearing-less cantilever design with direct-coupled IEC motor. Specially designed for plant engineering and confined spaces. The B80 HME Series can be operated beside the container in a dry-well installation. Liquid flowing up inside the shaft guide tube returns to the container via an overflow line. Pumps in dry-well installations allow an easier access to carry out maintenance and repair work. Features: Directly-coupled in bearing-less cantilever design Radial and axial fixed drive elements in two-piece bearing shell Pump housing in glass-fibre or carbon-fibre reinforced plastic (PP or PVDF) Gas seal for protecting the motor bearing Plastic-coated drive shaft Driven by IEC standardised motors Benefits: Compact dimensions Service-friendly dry-well installation Self-centring alignment in the bearing shell Vibration-free and...

Request for a quote

FRANKE GMBH

Germany

Franke FDH linear guides are suitable for linear movement tasks, especially in dynamic pick-&-place applications. They have rollers with angular contact ball bearings for the highest acceleration and speed values, for example when using linear motors as the drive source. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Adjustment of workstation systems through to complex mechanical engineering systems Lifting columns are the ideal drive elements when a motor setting is required in addition to the stable guidance. The whole technology is integrated and not visible from the outside. These lifting columns do not need any additional coverings. Usually, no special electrical knowledge will be required for the commissioning. Various versions are available as standard for the application in the field of medical technology. Several lifting columns can be combined and synchronised and offer further impressive application possibilities. The MultiControl-units can be linked by a BUS-system and enable the synchronization of maximal 32 lifting columns. The right Lifting column, quickly and easily Use our online product finder and compare lifting columns with each other, receive catalogue and CAD data or request the desired products directly.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ parts conveyors for ordered arranging, individualizing and conveying are used in every case where mass parts have to be supplied to a magazine, a machine or to installation equipment, item for item, with a pre-determined orientation and time. Advantages and benefits High level of conveying capacity with compact dimensions operationally safe in continuous employment synchronized two-mass vibration system no influencing of the vibration characteristics through the weight of the parts being conveyed maintenance-free drive conformity with all EC Guideline which affect the drives also available for explosion-endangered spaces (Ex), as well as for 60 Hz power systems and other mains voltages Construction and operation mode AViTEQ Parts conveyors are two-mass vibration systems, which are synchronized to be close to resonant condition. The drive part includes the elements for vibration generation, such as electromagnet and leaf spring packages. The arrangement of the simple leaf sprin

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Small part conveyor is used everywhere fine-grained bulk materials and not too unwieldy mass parts must be delivered, conveyed, dosed, added or assigned from storage tanks. AViTEQ has led the way in producing these devices and drives in Germany on a highest level standard. Advantages and benefits High level of conveying capacity with compact dimensions operationally safe in continuous employment No influencing of the conveying speed with different loading of the user device (conduit, trough, rail). Conformity with all EC Guidelines which affect the drives available for explosion-endangered spaces (ATEX; 94/9/EG) available for 60 Hz power systems and other mains voltages Construction and operation mode Small-scale conveyor equipment is based on synchronized two-mass vibration systems which are tuned close to resonant condition. The drive part includes the elements for vibration generation, such as electromagnet and leaf spring packages. The vibration amplitude (double amplitude

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

The AViTEQ Hopper discharge unit is used below hoppers, silos, bunkers or bulk containers for flowable bulk materials and serves as a combined closure, discharge, transportation and metering device. It is used where high material flows are required. Short hopper discharge units are mounted directly below the bulk hopper. Depending on the bulk material, the discharge unit can be fitted with appropriate protective linear and sealing systems. Advantages & benefits robust design and therefore long-lasting variable feeding speed with magnetic vibrator for optimal dosing to the process bunker closure without additional barriers arrangment central below the bunker run, simple and professional installation possible upon request, in a dust-tight design to save the environment Construction The main components are: conveyor bunker shoe for product guiding inside the feeder drive elastic support elements optional: flexible sealings optional: needle or blade gate for closing Selection The s

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high precision torque sensor is designed for both static and dynamic measurements on non-rotating applications. It is particularly suitable for torque measurements on, for instance, extremely small electrical actuating drives and micro-mechanical actuator elements, or for measuring reaction torques e.g. on micro-motors. The high accuracy of measurement also makes this sensor ideal for use as a reference in many fields of industrial manufacture as well as laboratory research and development projects. Not containing any rotating parts, it requires no maintenance if properly used. The strain-gage based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ±10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function.

Request for a quote

MAGTROL

Switzerland

DESCRIPTION The Torque Powder Brakes (TPBSeries) are ideal for applications operating in the low speed range or middle to-high torque range. These magnetic powder brakes provide full torque at zero speed and are convection or air cooled, allowing power ratings up to 900W (2100W with air cooling). APPLICATIONS These units are suited for tension control applications, such as wire winding, foil, film, and tape tension control. Mounted on test benches, TPB Series - Torque Powder Brakes allow performance and reliability testing on driving elements such as electric motors, hand-held power tools, geared motors, reduction gears, and hydraulic transmission systems. Other applications include load simulation for life testing on electric motors, actuators, gearboxes, power steering, and many other rotating devices and assemblies.

Request for a quote

ZETEK SP. Z O.O.

Poland

Precise CNC machining is currently the basis for the implementation of many production processes. Thanks to it, it is possible to manufacture details that are very complex in shape, such as gears, bearing elements, drive shafts, specialized tools or screws with non-standard parameters. It is used both in serial production and where prototypes are created and individual elements must be made based on technical drawings. It is also irreplaceable in the production of progressive tools . Precise CNC machining with the use of numerically controlled CNC machines also guarantees a very high repeatability of the elements made. At the same time, it reduces the time of their production and contributes to the economic use of materials, and as a result - to lower production costs. Such effects are determined both by the preservation of the set parameters throughout the production period of the series and the elimination of human errors. Precise CNC machining is also one

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

The rotary trommel / rotary drums are each designed for the respective application and transport requirements. Depending on your requirements, the bogies / rotary drums are equipped with different drive elements, plastic parts, lid variants, handles, labeling plates, inlays and offer an optimized cleaning coating quality for the end customer. Thanks to the optimized bogie, media and washing mechanics, e.g. ultrasonic or spray jet, reach the items to be cleaned from all sides. This contributes to improved cleaning quality, and extends also noticeably the water replacement cycle.

Request for a quote

NANJING LAB

United Kingdom

Binzhenghong hotplate is a digestion or acid drive equipment commonly used in elemental analysis laboratories. It is made of aluminum alloy or graphite, which heats up quickly and uniformly. Teflon PFA coating on the surface for effective corrosion protection. Its advantage is humanized customization(Its size can be customized according to the requirements of laboratory decoration). Exquisite details:The power cord is sheathed with PFA sleeves and no exposed metal parts, which minimizes interference to the experiment and has a longer service life. It has 4 strengths: 1. heating speed, full uniform heating 2.high efficiency,can heat several samples at the same time 3.simple operation, easy to use. Long service life 4. can customized different holds according to different utensils

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Dirt, moisture, abrasion and high mechanical loads: driving elements in agricultural machinery and the associated mounted implements are subject to severe strain. The bearings used also have to be tailored to these conditions. It is possible to increase the drive systems useful life by selecting the ideal bearings or using customised engineering. Special attention should be paid to the materials and seals. From the tractor the universal workhorse to combine harvesters, field choppers, beet harvesters and the many mounted implements for jobs such as ploughing, harvesting and fertilising, the drive systems for mobile agricultural engineering machines use bearings. These bearings have to operate in more extreme conditions than those used for many other applications.

Request for a quote

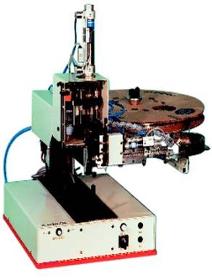

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 040/B Solder lug inserting with tape feeder Description The solder lug inserting device Type A 040 B, was constructed for a mechanised insertion of solder lugs. Fixed cycles of less than one second are within easy reach. A Foot pedal controls the individual stroke sequence. The taped solder lugs are automatically fed into the machine. Therefore, no additional material and wage costs for threading the solder lugs on leads will arise. The device is able to process all kind of taped solder lugs with standard forms. After a slight alternation, solder lug strips, which deviate from standard, can also be processed. To do this, you simply have to replace the insertion head with stripe guide and the cutting tool, which is fast and easy to do. All driving elements and electrical switches belong to the main machine and therefore, they do not have to be moved. The bearing pedestal for the material bin can hold coils up to 500 mm ø. An adjustable conical ring centres the coil on the bearing pedestal. Working with this device is very easy and save. Components

Request for a quote

NEUGART GMBH

Germany

The WPLPE is the smart right angle solution from our Economy Line: Space-saving, and yet powerful at an attractive price. You install your drive elements directly on the output shaft and extract the maximum flexibility from your application.

Request for a quoteResults for

Drive elements - Import exportNumber of results

29 ProductsCategory

- Gears (5)

- Mechanical transmission - components (3)

- Bearings - ball, needle and roller (2)

- Pinions (2)

- Transmission elements (2)

- Automation - systems and equipment (1)

- Chemistry - laboratory products (1)

- Clutches (1)

- Construction - Machines & Equipment (1)

- Conveyor belts (1)

- Energy - renewable (1)

- Gas turbines (1)

- Handling - Machines & Equipment (1)

- Mechanical transmission systems and components (1)

- Precision measuring instruments (1)

- Sensors (1)

- Steam turbines (1)

- Testing equipment (1)

- Toothed wheels (1)

- Transmission belts (1)