- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welded structures

Results for

Welded structures - Import export

GESTION CONTAINER

France

Volume: 4 m 3 Surface area: 3 m 2 Structure: Fully welded Corten Floors: 22 mm OSB / 21 mm marine plywood / 3+1 mm steel floor Fork passage: 950 mm Door opening : 270° Weight: 520/540 kg Weight maximum loading: 1,500 kg Number of European pallets: 2.

Request for a quote

GESTION CONTAINER

France

Volume: 18 m 3 Surface area: 10 m 2 Structure: Fully welded Corten Floors: 22 mm OSB / 21 mm marine plywood / 3+1 mm steel floor Fork passage: 950 mm Door opening : 270° Weight: 1,115/1,150 kg Maximum loading weight: 5,000 kg Number of European pallets: 4.

Request for a quote

GESTION CONTAINER

France

Volume: 10 m 3 Surface area: 4 m 2 Structure: Fully welded Corten Floors: 22 mm OSB / 21 mm marine plywood / 3+1 mm steel floor Fork passage: 950 mm Door opening : 270° Weight: 700/720 kg Weight maximum loading: 2,250 kg Number of European pallets: 2.

Request for a quote

THOMSON MACHINERY BV

Netherlands

1. 9KW air-cooling ATC spindle motor: Long working life, easy maintenance (HSD brand from Italy for option).2. Taiwan Delta Inverter: Guarantee the variety working speed and protect the spindle very well.3. Big steel square tube structure,by seamless welding and hardening treatment, guarantee it to be strong, reliable and durable, with large bearing capacity and long working life.4. Japan Yaskawa driving System with Shimpo reducer: With highly control precision and high speed, reliable and stable.5. Helical rack and pinion: quiet running, greater accuracy, smoother cutting and allows greater accelaration and feeding rates, longer lifetime because of smaller wearing force.6. High precision Taiwan TBI ball screw and Taiwan Hiwin linear square rails, which move smoothly to ensure the machining precision.7. Disc tool magazine, with Tool holders 12pcs, effectively improve working efficiency.

Request for a quote

THOMSON MACHINERY BV

Netherlands

1. The Thomson adopts advanced DSP system with USB connection, operated with handle, convenient operation.2. The whole machine is welded with seamless steel structure, which is high temperature annealing and vibrating stress relief, so the machine body is stabilized and will not be deformed forever.3. The ATC CNC adopts domestic top brand stepper motor to ensure high precision.4. Operating system has friendly easy operation interface, english suggestion and simple setting method.5. Spindle System is divided into single axial and biaxial.6. Transmission system adopts Hiwin square rail and ball screw to control the linear error effectively .7. One-time tool setting to finish the whole workpiece.8. Compatible with several CAD/CAM design software such as Type3, Artcam, etc.9. The ATC wood lathe can completely work offline and do not take any computer resources.10. 4th axis for 3D carving and cutting.11. Automatic tool changer system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TASK ITALY SRL

Italy

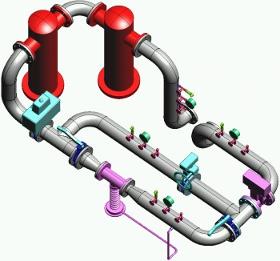

Isobaric Monoblocs for bottling carbonated liquids such as mineral water, soft drinks, beer, and sparkling wines. Comprising a rinsing turret (optional), a high-pressure filling turret, and a capping head for each closure type. The rotary filling groups are available starting from 6 valves and can be configured in various versions. The machine consists of a base with adjustable supports, welded to a rigid structure to reduce vibrations. On the base, you'll find the central support for the filler, the motorization, and gears that control the movements of both the screw conveyor and the bottle inlet/outlet stars. The isobaric tank is fixed to the cylinder-carrying flange via the tank height adjustment device. The specific filling valves are fixed to the isobaric tank. Equipped with a control panel featuring low-voltage buttons and thermal relays. Production: from 1,000 to 15,000 bottles per hour.

Request for a quote

VIRMER

Netherlands

WATTSAN M1 6090 machine has a working field of 600×900×200 mm with a slatted table cover. A spindle with an ER-20 collet chuck and a power of 1.5 kW, together with a water cooling system (for stable operation of the machine) are included in the basic package. The body of the machine is a welded structure made of steel profile, the weight of the machine is 500 kg. The maximum movement speed along the axes is 25000 mm/min, the maximum speed in operation is 15000 mm/min. Spindle speed can reach 25000 rpm. The machine is controlled by NcStudio software. To upgrade this machine, we can install: DSP controller.

Request for a quote

VIRMER

Netherlands

WATTSAN M1 2030 wide-format machine has a large working area of 2000×3000 mm with a slatted table top. The design includes a spindle with an ER-25 collet chuck and a power of 6 kW. An air cooling system and a built-in vacuum cleaner for collecting wood chips and dust are also available for an additional fee. The leadshine 860 stepper motor driver is responsible for moving the portal, the machine is controlled by the operator through NcStudio. The body of the machine is a welded structure made of steel profile, the weight of the machine is 1400 kg. The maximum travel speed along the axes is 25 000 mm/min, the maximum travel speed during operation is 15 000 mm/min. The spindle speed reaches 24 000 rpm. If you want a more upgraded machine, we can install: Vacuum table. DSP controller. Syntec control system. chip removal system. manual auto lubrication. more powerful spindle or additional cutting heads. rotary device for processing cylindrical products. tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М9 1325 has a working area of 2500х1300х200 mm and a T-slot slatted table. The complete set of the machine includes a water-cooled spindle with the power of 7.5 kW and ER-32 collet chuck. The portal is driven by YASKAWA servomotor and steppers. The milling machine is controlled by an operator through Weihong NCStudio control system. Unlike the junior model, this machine supports the automatic tool change option. The machine body is a welded structure made of steel profile; the weight of the machine is 1500 kg. The maximum travel speed along the axes is 50 000 mm/min; the maximum travel speed during operation is 20 000 mm/min. The spindle speed reaches 24 000 rpm. The machine is controlled by NCStudio software. On request, the machine can be equipped with a vacuum table, a DSP-controller, a Syntec control system, an aspiration system, a more powerful spindle or an additional spindle, a rotary device to process cylindrical objects, and a tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN A1 1313 machine has a working field of 1300×1300×200 mm, an ER-20 spindle with a power of 2.2 kW, and a water cooling system. A stepper motor controlled by the Yako 2405 driver is responsible for moving the portal. The body of the machine is a welded structure made of steel profile, the weight of the machine is 500 kg. The maximum travel speed along the axes is 25,000 mm/min, the maximum speed in operation is 15 000 mm/min. Spindle speed can reach 24000 rpm. The table has a slatted T-slot cover. The machine is controlled by NcStudio software. To upgrade this machine, we can install: vacuum table. DSP controller. Chip removal system. Manual auto lubrication. More powerful spindle or additional cutting heads. Rotary device for processing cylindrical products. Tool sensor.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

SKID PRESSURIZATION FOR PLANES INFLATING BENCHES - Stainless skid including the whole instrumentation necessary for piloting - Air filter - Automaton and supervision piloting - Various pressures acquisition - Pressure control at 1,2 mbar/s TOOLING PDOS : POWER DOOR OPENING SYSTEM : This tooling permit: - PDOS electrical supply in 115Vac/400 Hz and in 28Vdc le PDOS, - The jack purge of the driving hoods, - Driving hoods opening and closure (Fan and reverses), - Secure the staff during the operation. HEATED BOX FOR COMPOSITE MATERIAL : - 6 m length welded structure, - Heated box 5,5 m length x 1,5m width, - Heated box flatness 5/10 mm/m, - Vacuous putting system 600mbar, - Temperature setting nd cooling by heat transfer fluid, - Heating capacity of 150kW, - Automaton and supervision piloting

Request for a quote

COMPANY TOR

Russia

The Russian-manufactured inverter machine ТОРУС-320 is used for manual arc welding of metal blanks. The inverter has a functional control panel with a digital display that displays the main operating parameters. The metal housing is equipped with large ventilation holes in order to prevent overheating of internal components. The device is equipped with overload protection and voltage surge protection. The technologies applied during the manufacture of ТОРУС-320 devices allow performing any tasks in welding, surfacing and cutting metal structures for performing work with any kind of electrodes with a diameter of up to 6 mm and a maximum arc welding current of up to 320A (100% at 300A). The welding inverter machine can be used at low temperatures and reduced supply voltage.

Request for a quote

COMPANY TOR

Russia

The inverter machine VIKING 500A PRO is used for manual arc welding of metal blanks. The inverter has a functional control panel with a digital display that displays the main operating parameters. The device is equipped with overload protection and voltage surge protection. The technologies applied during the manufacture of VIKING 500A PRO devices allow performing any tasks in welding, surfacing and cutting metal structures for performing work with any kind of electrodes with a diameter of up to 6 mm and a maximum arc welding current of up to 500А (100% at 420 A). The welding inverter machine can be used at low temperatures and reduced supply voltage. Adjustable functions of hot start and arc reheat imply the ability to adjust the operation of the device with minimal spattering and allow you to perform work in any spatial position of the electrode and welded surfaces.

Request for a quote

FRIMO GROUP GMBH

Germany

Hydraulic presses for a broad variety of pressing, foaming, punching and forming tasks FRIMO HyPress standard machines can be adapted to fit table size, stroke, clearance, and press force requirements. Numerous options are available including safety packages, pivoting rams and tables, tool change systems, automation solutions, and complete customizations. The standard presses are designed as bolted, welded structures. The machine feet, head and sides are manufactured with high precision and fastened with fitting keys. The ram is guided via prisms and can be easily readjusted. It can alternatively be column-guided.

Request for a quote

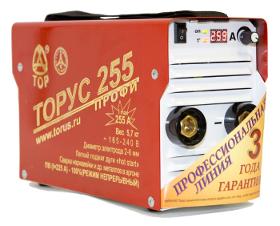

COMPANY TOR

Russia

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quoteResults for

Welded structures - Import exportNumber of results

16 ProductsCompany type

Category

- Milling - machine tools (4)

- Welding work - steels and metal (3)

- Autogenous welding machines (3)

- Containers (3)

- Welding, soldering and brazing - equipment and supplies (3)

- Paper - Printing - Machines & Equipment (2)

- Harvesting machinery and equipment (1)

- Wine-making - machinery, equipment and plants (1)