- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool system

Results for

Tool system - Import export

IGUS® GMBH

Germany

chainflex® robot cables are used in energy chains or 3D applications. The twistable robot cables meet extremely high industrial stress requirements and score points with properties such as resistance to hydrolysis and microbes, UV resistance and many, many others. Different types of robot cable are available, e.g. hybrid cables, fibre optic cables (FOCs), motor cables and servo cables. Typical application areas: - For heavy duty applications - Almost unlimited resistance to oil - Indoor and outdoor applications with average solar radiation - Unsupported travel distances and up to 100 m for gliding applications - Machining centres / machine tools, storage and retrieval systems, packaging industry, handling, refrigerating

Request for a quote

IGUS® GMBH

Germany

E4Q energy chains have been developed to provide the best possible solution for unsupported and long travels. Based on the robust E4.1 energy chain standard, which has proven itself over 12 years, the new series brings a long service life and high modularity. - Tool-free opening and closing - Reduced protrusions in the interior, for easier filling when the e-chain® is open - 15 % more pull-out force of the opening webs compared to the E4.1 system - 10 % less weight due to material recesses compared to system E4.1 - Optional 17 dB(A) quieter due to noise-reducing parts made of material optimized for noise level - 40 % less installation time compared to system E4.1 - Up to 35 % savings possible when used in the limit range - 36 months warranty - Predictive maintenance - optional with the isense add-on module Typical applications: Machine tools, crane systems, automation systems

Request for a quote

THOMSON MACHINERY BV

Netherlands

1. 9KW air-cooling ATC spindle motor: Long working life, easy maintenance (HSD brand from Italy for option).2. Taiwan Delta Inverter: Guarantee the variety working speed and protect the spindle very well.3. Big steel square tube structure,by seamless welding and hardening treatment, guarantee it to be strong, reliable and durable, with large bearing capacity and long working life.4. Japan Yaskawa driving System with Shimpo reducer: With highly control precision and high speed, reliable and stable.5. Helical rack and pinion: quiet running, greater accuracy, smoother cutting and allows greater accelaration and feeding rates, longer lifetime because of smaller wearing force.6. High precision Taiwan TBI ball screw and Taiwan Hiwin linear square rails, which move smoothly to ensure the machining precision.7. Disc tool magazine, with Tool holders 12pcs, effectively improve working efficiency.

Request for a quote

THOMSON MACHINERY BV

Netherlands

1. The Thomson adopts advanced DSP system with USB connection, operated with handle, convenient operation.2. The whole machine is welded with seamless steel structure, which is high temperature annealing and vibrating stress relief, so the machine body is stabilized and will not be deformed forever.3. The ATC CNC adopts domestic top brand stepper motor to ensure high precision.4. Operating system has friendly easy operation interface, english suggestion and simple setting method.5. Spindle System is divided into single axial and biaxial.6. Transmission system adopts Hiwin square rail and ball screw to control the linear error effectively .7. One-time tool setting to finish the whole workpiece.8. Compatible with several CAD/CAM design software such as Type3, Artcam, etc.9. The ATC wood lathe can completely work offline and do not take any computer resources.10. 4th axis for 3D carving and cutting.11. Automatic tool changer system.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer INDEX Model ABC 65 Year 2002 Condition Used Made in Germany Control unit SIEMENS Sinumerik X-Axis travel 90 mm Y-Axis travel +/- 50 mm Z-Axis travel 280 mm Number of axis 4 (with C-Axis) Spindle speed 5000 rpm Max. Swing 65 mm Working length 280 mm Motor power 35 kW Number of Turrets 2 Turret 1 7 driven tool stations Turret 2 System with 6 dovetail slide ways Bar feeder L 5140 x W 850 x H 1300 mm

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Hi-Tech Impulse Tool with Double Chamber Air Motor. The lightweight Yokota YLa series impulse wrenches with double chamber air motor achieve the required torque very quickly. The tools have a high number of impulses per second, and therefore very accurate torques can be realised, resulting in increased production speed. Design innovation and the application of new materials significantly reduce the weight and increase the service intervals. Yokota impulse wrenches are widely used for tightening jobs in the assembly industry, where accurate torque tolerances are necessary. Impulse tools are light, powerful, small and very importantly, have no kick-back. Evaluation of tightening processes in car assembly shows that tightening joints uses 10% of the total assembly time. Working with faster tools therefore can speed up assembly lines substantially. [...]

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Hi-Tec Shut-Off Impulse Tool. The lightweight Yokota YLT series impulse wrenches with double chamber air motor achieve the required torque very quickly. The tools have a high number of impulses per second, and therefore very accurate torques can be realised, resulting in increased production speed. Design innovation and the application of new materials significantly reduce the weight and increase the service intervals. Yokota impulse wrenches are widely used for tightening jobs in the assembly industry, where accurate torque tolerances are necessary. Impulse tools are light, powerful, small and very importantly, have no kick-back. Evaluation of tightening processes in car assembly shows that tightening joints uses 10% of the total assembly time. Working with faster tools therefore can speed up assembly lines substantially. [...]

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

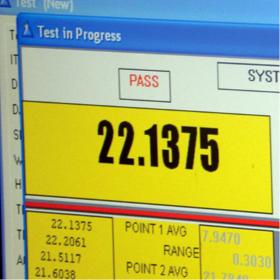

The Perfect Database for the Control of Torque Tool Calibration Torque Tool Manager 4.0 software is calibration and certification specifically designed to work with System 8® and Torq-Tronics 2® Digital Torque Testers! It will fulfill your TS 16949 and ISO calibration certificate requirements far more cost-effectively than manual record keeping systems! Torque tool calibration requires attention to detail in every respect, and maintenance of records pertinent to all factors - as well as creating certificates of calibration for each calibrated item. When all of this can be automated the process becomes more efficient, less prone to error, and less costly to operate. Torque Tool Manager, used with SR digital torque testers, improves control and efficiency for almost all of the operations. Specifications and tester settings are stored in the software and downloaded to the tester exactly when needed. The technician is guided and supported by the software during the testing, and...

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Hardwired Tool Use Control. The hardwired preset clicker-type torque wrenches are based on Sturtevant Richmont's legendary LTC/LTCR/LTCS lines of preset torque wrenches. These tool add a tool use control to the accurate, repeatable and durable LTC group of tools by measuring time in the “clicked” position. This reduces operator technique variation through immediate reporting and reinforcement of correct use technique. These tools are ideal for those who wish in inexpensive and highly effective control and who have the PLC and knowledge resources to implement the communication and feedback system. The tool's light weight and cushion grip provide excellent ergonomics and reduce the onset and level of operator fatigue. The ball bearing rockover mechanism enhances the accuracy, repeatability, and durability high-throughput assembly operations require! The torque can be set using any unit of torque measurement: Imperial, S.I., or metric. [...]

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

The 2100PTP Series Wireless Power Tools are designed to work with the Global 400 and Global 400mp controller systems. These wireless tools are designed for industrial assembly use. The tool is completely dependent on the Global 400/400mp for directions and torque results reporting. Details on learning and programming the tool through the Global 400/400mp controllers may be found in the controller manual. Model 2100PTP-12: 3-12 Nm / 700-100 RPM Key Highlights Adjustable clutch sets torque limit Report OK/NOK results Kits come with an adjustment tool Double hit detection

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

The 2200PTP Series Wireless Power Tools are designed to work with the Global 400 and Global 400mp controller systems. These wireless tools are designed for industrial assembly use. The tool is completely dependent on the Global 400/400mp for directions and torque results reporting. Details on learning and programming the tool through the Global 400/400mp controllers may be found in the controller manual. Models 2200PTP-18: 3-18 Nm / 50-100 RPM 2200PTP-24: 6-24 Nm / 50-600 RPM Key Highlights Report torque/angle values with the results Kits come with side handle

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

The 2100PTA Series Wireless Angled Power Tools are designed to work with the Global 400 and Global 400mp controller systems. These wireless tools are designed for industrial assembly use. The tool is completely dependent on the Global 400/400mp for directions and torque results reporting. Details on learning and programming the tool through the Global 400/400mp controllers may be found in the controller manual. Models 2100PTA-45: 18-45 Nm / 210-300 RPM 2100PTA-90: 40-90 Nm / Fixed 100 RPM Key Highlights Adjustable clutch sets torque limit Report OK/NOK results Kits come with an adjustment tool Double hit detection Adjustable speed defined by controller parameter (2100PTA-45 only)

Request for a quote

APD MAQMASTER

Spain

Numerical Control Panel Processing Machine 3-axis. Designed for joining, cutting, and panel operations and plates. Thanks to its exclusive automatic change system of tool change, reduces tool change time to 2.5 seconds and minimizing downtime and not Produced. Allows the machining of wood, plastic and various materials by changing milling tools.

Request for a quote

APD MAQMASTER

Spain

Numerical Control Panel Processing Machine 3-axis. Designed for joining, cutting, and panel operations and plates. Thanks to its exclusive automatic change system of tool change, reduces tool change time to 2.5 seconds and minimizing downtime and not Produced. Allows the machining of wood, plastic and various materials by changing milling tools.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

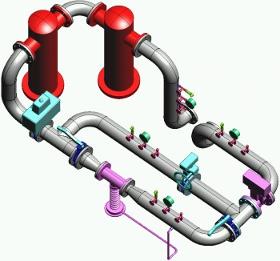

SKID PRESSURIZATION FOR PLANES INFLATING BENCHES - Stainless skid including the whole instrumentation necessary for piloting - Air filter - Automaton and supervision piloting - Various pressures acquisition - Pressure control at 1,2 mbar/s TOOLING PDOS : POWER DOOR OPENING SYSTEM : This tooling permit: - PDOS electrical supply in 115Vac/400 Hz and in 28Vdc le PDOS, - The jack purge of the driving hoods, - Driving hoods opening and closure (Fan and reverses), - Secure the staff during the operation. HEATED BOX FOR COMPOSITE MATERIAL : - 6 m length welded structure, - Heated box 5,5 m length x 1,5m width, - Heated box flatness 5/10 mm/m, - Vacuous putting system 600mbar, - Temperature setting nd cooling by heat transfer fluid, - Heating capacity of 150kW, - Automaton and supervision piloting

Request for a quote

FRIMO GROUP GMBH

Germany

Processing sound-absorbing materials such as textiles, carpets or foamed materials requires efficient and high quality system technology. FRIMO supplies tailor-made solutions for insulation and acoustic component manufacturing for vehicles or other applications which require noise-cancellation.

Request for a quote

FRIMO GROUP GMBH

Germany

Composites are engineered materials made from two or more materials with significantly different physical or chemical properties. Their mechanical and physical properties depend on the type and proportion of the base materials and the parameters of the manufacturing process. Due to composites, very light and durable plastic parts can be produced. Composites may be prepared as layers , fibers, particles or penetrating composites , but the actual composite material usually only arises during the shaping process in the tool . FRIMO has extensive technical expertise and many years of experience in developing and manufacturing plants and tools to process composite materials such as CFK, GFK, NFPP, HFPP, LFT, GMT and BMC and supplies for the production processes such as RRIM, SRIM / GMPU, Long Fiber Technologies, NFI, or RTM tailor-made manufacturing equipment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

Hydraulic presses for a broad variety of pressing, foaming, punching and forming tasks FRIMO HyPress standard machines can be adapted to fit table size, stroke, clearance, and press force requirements. Numerous options are available including safety packages, pivoting rams and tables, tool change systems, automation solutions, and complete customizations. The standard presses are designed as bolted, welded structures. The machine feet, head and sides are manufactured with high precision and fastened with fitting keys. The ram is guided via prisms and can be easily readjusted. It can alternatively be column-guided.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming and scoring hidden airbag compartments on thermoformed skin. After the fabrication of IP skins through thermoforming, two separate fabrication steps are still needed before foaming. In the first step, the thermoformed skin will be trimmed in the external zone through punching or a blade cutting process. Depending on the requirements, this is where FRIMO's blade cutting equipment comes into operation. In the second step, the skin will be weakened in the airbag area by a blade. By using the new FRIMO FlexTrim Combi Trim Scoring machine, both steps can be realised at once. The skin is positioned in a common component fixture and finished with two different cutting tools. The new system concept, with its flexible design and layout possibilities, offers a variety of options for combinable process and operation groupings. As an example : one 2-station system with two robots, which are equipped with automatically exchangeable cutter heads, and where two different products

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

The oxygen bottle is connected to SÖHNGEN® pressure regulator by hand connection system without any tools! Features of the oxygen bottle: Filling pressure 200 bar Test pressure 300 bar Cylinder coat painted white outside Inside are sandblasted Against corrosion protected Cylinder valve 19,8 DIN 477, chrome, with gum hand wheel Available in 1, 2 as well as 5 or 10 l Support feet (only with 10l- bottle) Height 345 – 980 mm Diameter 83 – 140 mm Weight 2.3 – 16.4 kg

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

Pressure regulator SÖHNGEN® is a precision device with an individually, step less adjustable dosage of oxygen (0-15l/min). Moreover it convinces by following features: Compact design Clear and large scale Matt chrome, sandblasted surface Connection bushing with standard thread Hand connection system without tools For all cylinder valves according to DIN 477-1;1995, no. 9 usable In accordance with UVV Oxygen BGV B7 (so far VBG 62) Certified by Federal Institute of material testing

Request for a quote

DOMINO SIGN

France

SuperChannel Bender XP automatically performs the edges of your letters from coils of aluminum, stainless steel, profiles and other materials 0.6 to 1.6 mm thick and 20 to 200 mm high ( see table of characteristics). The flat bands are folded thanks to: a tool of reinforcement folds (Flange Tool) facilitating the fixing of the bottom of the letters to the edges. a grooving tool allowing the bending of acute angles. a new innovative hole-drilling system (Punching Tool) for direct riveting of the strip on the bottom. Coupled with the automatic management of an Overlap and the use of pre-lacquered strips, this machine allows you to save the usual operations of welding the base and painting the edge!

Request for a quote

PRECITOOLS SRLS

Italy

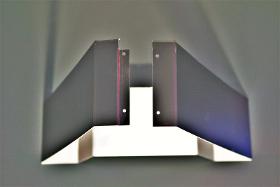

Press brake tools for machines: Accurl, Adira, AM Machinery, Amada, Augusta, Axial, Baykal, Boschert, Bystronic, CMU, CoastOne, Colgar, Colly, Gasparini, Gilardi, Gizelis, Guifil, Dener Makina, Deratech, Durma, Edward Pearson, Ermaksan, Euromac, Femas, Fratelli Farina, GADE, Gasparini, Gecko, HACO (Atlantic), Hammerle, Hesse, Hezinger, Hilalsan, IMAL, Inanlar, Ironmac, ITEK, Jean Perrot, Jordi, KAAST, Karmet, Kingsland, Knuth, LAG, Mecos, MVD, Muratec, Nargesa, OMAG, Peliant, Rico, Salvagnini, Schiavi, SMD, STR, Tabama, TCI etc. We supply solid pieces 415, 835 mm; section set (cutted) 805 mm and complete sets for the full length of your press brake. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Bystronic-Beyeler (Euro-A, RF-A, R, S), Edwards Pearson, Safan, Bystronic, Beyeler etc. We supply solid pieces 100, 500, 1000 mm; section set (cutted) 1100 mm and complete sets for the full length of your press brake. Dies could be used with Trumpf-WILA system. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Bystronic-Hammerle, Durma, EHT, Finn-Power, Jordi, Gizelis, LVD, Trumpf, Prima Power, RICO PRCN, Safan-Darley, STR, Ursviken etc. We supply solid pieces 100, 200, 300, 500 mm; section set (cutted) 550 mm and complete sets for the full length of your press brake according to the customized pieces or the same as original tooling. For TRUMPF-WILA press brake tools we can offer 100% compatible tools as original. Dies could be used with Beyeler-Bystronic system. Any punches for Trumpf-Wila with low weight could be equipped with push buttons for quick frontal extraction. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

Special tools for customized applications and parts including forming, several bends in one stroke, controlled deformation, coining and stamping etc. The special press brake tools could be supplied for any press brake and system. We can also deliver as specials press brake tools for American style tools, LVD system, EHT system, COLLY - AJIAL system, HACO system and many others.

Request for a quoteResults for

Tool system - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Industrial tools (7)

- Bending machine tools (5)

- Paper - Printing - Machines & Equipment (3)

- Precision engineering - portable power tools (3)

- Compressed air tools and systems (2)

- Machine tools - metal machining (2)

- Tightening wrenches (2)

- Electric cables (1)

- Calibration equipment (1)

- Laser - cutting and welding machines (1)

- Chains with articulated links (1)