- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool holder

Results for

Tool holder - Import export

THOMSON MACHINERY BV

Netherlands

1. 9KW air-cooling ATC spindle motor: Long working life, easy maintenance (HSD brand from Italy for option).2. Taiwan Delta Inverter: Guarantee the variety working speed and protect the spindle very well.3. Big steel square tube structure,by seamless welding and hardening treatment, guarantee it to be strong, reliable and durable, with large bearing capacity and long working life.4. Japan Yaskawa driving System with Shimpo reducer: With highly control precision and high speed, reliable and stable.5. Helical rack and pinion: quiet running, greater accuracy, smoother cutting and allows greater accelaration and feeding rates, longer lifetime because of smaller wearing force.6. High precision Taiwan TBI ball screw and Taiwan Hiwin linear square rails, which move smoothly to ensure the machining precision.7. Disc tool magazine, with Tool holders 12pcs, effectively improve working efficiency.

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 2003 CNC control : MITSUBISHI Meldas 635LCC Stroke X1 axis : 170 [mm] Stroke Z1 axis : 200 [mm] Stroke X2 axis : 110 [mm] Stroke Z2 axis : 395 [mm] Stroke X3 axis : 110 [mm] Stroke Z3 axis : 170 [mm] Type of tool holders : VDI 20 Spindle for collets : Taille 48 DIN 6343 Spindle throughbore : 42 [mm] Min. spindle speed : 80 [rpm] Max. spindle speed : 8000 [rpm] Increment C-axis : 0.001 [°] Spindle power : 7.5 [kW] Counter spindle throughbore : 42 [mm] Min. counter spindle spindle speed : 60 [rpm] Max. counter spindle speed : 6000 [rpm] Counter spindle increment C-axis : 0.001 [°] Counter spindle power : 2.2 [kW] Max. turning diameter : 140 [mm] Number of tool stations - Upper turret : 12 Number of tool stations driven - Upper turret : 12 Max. speed driven tools - Upper turret : 4500 [rpm] Number of tool stations - Lower turret : 12 Number of tool stations driven - Lower turret : 12 Max.

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing :2004 CNC control: FANUC 180i-MB Stroke X axis: 500 [mm] Min. Stroke speed X axis: 0.0001 [mm/min] Max. Stroke speed X axis: 2000 [mm/min] Stroke Y axis: 300 [mm] Min. Stroke speed Y axis: 0.0001 [mm/min] Max. Stroke speed Y axis: 2000 [mm/min] Stroke Z axis: 140 [mm] Min. Stroke speed Z axis: 0.0001 [mm/min] Max. Stroke speed Z axis: 2000 [mm/min] Stroke W axis: 350 [mm] Planetary speed C axis: 1 - 300 [rpm] C axis max. speed: 20 [rpm] Max. Stroke speed W axis: 2000 [mm/min] Stroke U axis (radial feed): 11 [mm] Table length: 610 [mm] Table width: 305 [mm] Supply voltage: 400 [V] ADDITIONAL INFORMATION: x1 spindle DÄNZER DHB 0911.000 WW x1 oil cooler TURMOIL model OCO-33 RO x1 mist extraction unit FILTERMIST model F600 x1 MOORE Autosize tool edge probe x1 MOORE TOOL automatic wheel dresser x16 tool holders x1 RENISHAW OMP 40 workpiece probe x1 MOORE TOOL clamping box Full technical documentation

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 2000 CNC control : FANUC 18i-T Number of axes : 5 Max. turning lenght : 205 mm Max. bar diameter in turning spindle : 20 mm Max. spindle speed : 8000 rpm Increment C-axis : 0.001 ° Spindle power : 3.7 kW Max. bar diameter counter spindle : 20 mm Max. counter spindle speed : 4500 rpm Counter spindle increment C-axis : 0.001 ° Counter spindle power : 1.1 kW Number of positions end attachment : 4 Number of motorized positions end attachment : 4 Number of positions guide bush holder 1: 6 Number of motorized positions guide bush holder 1 : 4 Live tools speed guide bush holder 1 : 5000 rpm Number of positions secondary operation : 4 Number of motorized positions secondary operation : 4 Lubrication tank capacity : 155 [l] Supply voltage : 400 V RS232 Interface : Yes Number of running hours : 40920 [h] Weight : 2200 Kg x1 IEMCA Genius 226/32 barfeeder x4 live turning tool holders x1 rotating guide bush x1 parts catcher x1 coolant tank

Request for a quote

KRAFFTER MACHINE TOOLS

France

CNC control: Fanuc 0i-TB Number of axes: 7 Max. cutting diameter: 42 mm Max. turning length: 100 mm Stroke Z1 axis: 246 mm Stroke X1 axis: 165 mm Stroke Y1 axis: +/- 40 mm Stroke Z2 axis: 525 mm Stroke X2 axis: 70 mm Rapid traverse rate X axis: 18000 mm/min Rapid traverse rate Z axis: 20000 mm/min Rapid traverse rate Y axis: 12000 mm/min Spindle through bore: 43 mm Min. spindle speed: 60 rpm Max. spindle speed: 6000 rpm Increment C-axis: 0.02 ° Spindle power: 11 kW Counter spindle through bore: 36 mm Min. counter spindle spindle speed: 67 rpm Max. counter spindle speed: 7000 rpm Counter spindle increment C-axis: 0.02 ° Counter spindle power: 5.5 kW Max. tool holder cross-section: 20 mm Number of tool stations driven - Turret 1: 12 Max. speed driven tools - Turret 1: 4000 rpm Indexing time - Turret 1: 0.25 s/post Number of tool stations - Turret 2: 6 Indexing time - Turret: 0.20 s/post Live tools power: 2.5 kW + EQUIPMENT INCLUDED Machine visible under power

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

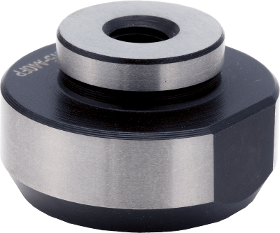

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Excellent workpiece accessibility Workpiece centralizing on flang work holders. Flange work holders These central bosses are used for workpiece location on the Klamp range of flange work holders.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Accepts a variety of workholders Excellent workpiece accessibility In the case where you can’t mount the head directly to your machine table, please use this mounting plate. We can supply a blank that is customisable and also manufacture a special mounting plate just for you. For more information, please feel free to contact us.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Excellent workpiece accessibility The dovetail clamping work-holder with the HSK head works with heavy-duty milling. All Swift Klamp Dovetail work holders are attached to the workpiece usinga simple dovetail. Setup is quick, easy and dovetail work holders only require the minimum of material to hold the workpiece. That means less waste, easy preparation, and no distortion to the workpiece.Dovetail machining of the work-piece clamping area using an angular cutter is required prior to machining

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

16 1/2" x 80" GAP BED CAPACITY. 3 & 4 JAW CHUCKS. QUICK CHANGE TOOL POST PLUS HOLDERS. 3 POINT STEADY. 2 1/2" SPINDLE BORE. 24 1/2" SWING IN GAP. 40 - 2000 RPM AINJEST RAPID THREADING SCREW GAURD

Request for a quoteResults for

Tool holder - Import exportNumber of results

10 ProductsCompany type