- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool changer

Results for

Tool changer - Import export

APD MAQMASTER

Spain

It has a fixed 8-position tool changer and a carriage to which another tool changer can be attached, always with 8 positions. Thanks to its numerous versions, 1500×3000, 1650×4000, 1650×6000, 2000x 4000 and 2000×8000, the PWI has found various applications in the industrial sector, for example in plastics, aluminum and agglomerates in general. Special versions can be supplied for milling and threading steel profiles and/or bars. PWI offers a wide Z to hold i supports and to hold particular profiles. In its complete version with clamps, it allows alternating compounds and profiles, in order to optimize the machine for different applications in a single work environment. This machine is usually chosen for its versatility and speed, with an interpolation of up to 40 m/min. In this case, CADCAM ITALMAC provides this version of CNC with all the DXF and geometric figure import tools, so that the PWI is recognizable compared to other similar machines.

Request for a quote

APD MAQMASTER

Spain

Available in 4, 9 and 11 meter versions, it is especially suitable for machining steel and aluminum. It is equipped with powerful 20, 24 or 30 kW electrospindles, both asynchronous and synchronous, which guarantee maximum efficiency thanks to the liquid cooling system. The machine can be placed in the medium-heavy industrial sector. With this machining center, Italmac places itself among the highest-performance machining workshops. THOR is a rigid center with a gantry structure with slack recovery and hydraulic closing jaws, which guarantee a secure grip. It is also equipped with: a tilting head that, thanks to its hydraulic brakes, guarantees rigidity during machining , a tool changer with 15 to 30 positions, an automatic tool probe and a metal chip evacuation belt.

Request for a quote

APD MAQMASTER

Spain

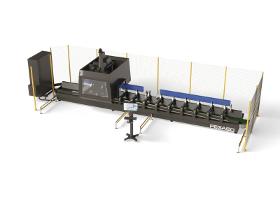

Available in versions of 4, 7, 9, 11 and 13 meters also with double clamping and with supports for angular heads suitable for specific processes. Your basic tool changer includes 15 positions, but can be expanded to 30 upon request. The 300 x 640 mm machining section allows a wide range of operations to meet any need. Among its most notable features, PEGASO includes: a 400mm blade and a tool blade that can be combined with the 500mm accessory blade unit. PEGASO is perfect for facades, building profiles, automotive industry, lighting technology, railway sector and all light industries in general. The Pegaso machining center is a high-power, high-precision machine designed for CNC machining parts in various materials, such as metal, plastic and wood.

Request for a quote

THOMSON MACHINERY BV

Netherlands

1. The Thomson adopts advanced DSP system with USB connection, operated with handle, convenient operation.2. The whole machine is welded with seamless steel structure, which is high temperature annealing and vibrating stress relief, so the machine body is stabilized and will not be deformed forever.3. The ATC CNC adopts domestic top brand stepper motor to ensure high precision.4. Operating system has friendly easy operation interface, english suggestion and simple setting method.5. Spindle System is divided into single axial and biaxial.6. Transmission system adopts Hiwin square rail and ball screw to control the linear error effectively .7. One-time tool setting to finish the whole workpiece.8. Compatible with several CAD/CAM design software such as Type3, Artcam, etc.9. The ATC wood lathe can completely work offline and do not take any computer resources.10. 4th axis for 3D carving and cutting.11. Automatic tool changer system.

Request for a quote

THOMSON MACHINERY BV

Netherlands

1. 9KW air-cooling ATC spindle motor: Long working life, easy maintenance (HSD brand from Italy for option).2. Taiwan Delta Inverter: Guarantee the variety working speed and protect the spindle very well.3. Big steel square tube structure,by seamless welding and hardening treatment, guarantee it to be strong, reliable and durable, with large bearing capacity and long working life.4. Japan Yaskawa driving System with Shimpo reducer: With highly control precision and high speed, reliable and stable.5. Helical rack and pinion: quiet running, greater accuracy, smoother cutting and allows greater accelaration and feeding rates, longer lifetime because of smaller wearing force.6. High precision Taiwan TBI ball screw and Taiwan Hiwin linear square rails, which move smoothly to ensure the machining precision.7. Disc tool magazine, with Tool holders 12pcs, effectively improve working efficiency.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

THOMSON MACHINERY BV

Netherlands

Manufacturer Morbidelli Model Author M100 Year 2018 Condition Used Control unit SCM eye-M Axis 5 X-Axis travel 3110 mm Y-Axis travel 1620 mm Z-Axis travel 180 mm Tool changer 28 HSK F63 Bars 6 Vacuum pump 250 m3/h Availability Immediately

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 2020 CNC control : HEIDENHAIN TNC 640 Number of simultaneous axes : 5 Stroke X axis : 650 mm Stroke Y axis : 850 mm Stroke Z axis : 500 mm Traversing feeds X, Y and Z axes : 36000 mm/min X axis ball screw, Ø x pitch : 40 x 12 mm Y axis ball screw, Ø x pitch : 40 x 12 mm Z axis ball screw, Ø x pitch : 40 x 12 mm Angular A axis stroke : +/- 120 ° Angular C axis stroke : 360 ° Min. distance spindle nose / table : 150 mm Max. distance spindle nose / table : 650 mm Spindle type : HSK-A 63 Max. spindle speed : 20000 rpm Tool changer magazin number of stations : 60 Max. tool length : 300 mm Max. weight of single tool : 8 Kg Total max. weight in tool changer magazine : 480 Kg Max. tool diameter : 125 mm Total power required : 60 kVA Number of hours under power : 5683 h Number of running hours : 3183 h Machine weight : 12000 Kg Machine dimensions : 3390 x 3940 x 2970 mm With equipment

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing : 2018 CNC control : HEIDENHAIN iTNC 640 Number of simultaneous axes : 5 Stroke X axis : 2000 [mm] Stroke Y axis : 600 [mm] Stroke Z axis : 550 [mm] Feed rate on X, Y and Z axes : 20000 [mm/min] Traversing feeds X, Y and Z axes : 40000 [mm/min] Axes acceleration : 2.5 [mm/sec²] Min. distance spindle nose / table : 30 [mm] Table length : 1250 [mm] Table width : 800 [mm] Max. load on table : 500 [Kg] Rotary tilting table surface : 600 x 600 [mm] Stroke C axis : table revolution : 360 [°] Max. speed C axis : 25 [rpm] B axis swivelling stroke : -110 / +110 [°] Spindle type : ISO 40 Max. spindle speed : 15000 [rpm] Spindle power : 17 [kW] Tool changer magazin number of stations : 80 Max. tool length : 300 [mm] Max. weight of single tool : 7 [Kg] Total max. weight in tool changer magazin : 400 [Kg] Total power required : 57 [kVA] Supply voltage : 400 [V] Number of hours under power : 17840 [h] Weight : 15000 Kg

Request for a quoteResults for

Tool changer - Import exportNumber of results

9 ProductsCountries

Company type