- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tig welding

Results for

Tig welding - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Numerically-controlled hydraulic press brake, numerically-controlled hydraulic shearing machine, numerically-controlled machining centres, numerically-controlled lathes and milling machines, mortising machines, presses, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting workstation, paint booth, assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment, testing and programming workstations, etc. With our diverse range of facilities and modular covered areas, we can manufacture practically any type of installation or equipment, with unlimited space and technological expertise. Our multidisciplinary team of highly qualified specialists, combining long-standing experience with the technical skills of youth, guarantees the optimal operation of our equipment and the quality of the facilities delivered to you.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

In addition to being able to work on site in an emergency to diagnose an unexpected breakdown and repair your installation, we are equipped with: a comprehensive machine fleet (numerically-controlled machining centres, lathes and milling machines, mortising machine, press, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting station) meaning that we can manufacture products to measure and supply all your replacement and wear parts in an emergency an assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment and testing and programming stations, where mechanical and electrical assemblies and sub-assemblies can be produced urgently and with a high degree of flexibility

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Our metal work unit is equipped with all the equipment required to carry out the majority of operations related to the production and shaping of metal objects: mortising machine, press, drilling machines, rolling machines, semi-automatic welding stations and TIG/Plasma/Oxycutting workstations. Our vast range of metal work equipment and the adaptability of the workshop’s covered areas are ideal for performing almost every type of shaping.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electrical flange type immersion heaters The range of immersion heaters type FHK offers an economic heating solution for process tanks, pressure vessels and similar plant. The standard heater consists of a number of rod elements TIG welded into a process flange. A robust terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

EEx’e‘ certified immersion heater EEx e T1 – T6 ATEX The “FHK-Exe” type electric immersion heaters are EExe certified. These heaters are custom built to meet client specifications and suitable for use in zone 1 & 2 hazardous areas. The range of immersion heaters type FHK-Exe offers an economic heating solution for process tanks, pressure vessels and similar plant. The standard heater consists of a number of rod elements TIG welded into a process flange. A robust Ex’e’ terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Advanced inverter technology for superior TIG DC performance. Industrial TIG welder for difficult conditions. The fully functional and user-friendly control panel, with graphical and numeric display, makes it easy to set all welding parameters. Robust construction: electrical safety (IP23S), protected printed circuit boards and optimal airflow reduce contamination to extend equipment life in the harshest environmental conditions. TIG HF and Lift ignition meets all requirements. Perfect start of the TIG HF with pre-defined start mode. Complete configuration of TIG parameters: Pulse TIG with variable frequency that allows the welder to adjust the arc focus according to applications, 10 memory positions for personalized welding settings, TIG spot welding. Water coolers and carts available What's included: Input cable (2m) Gas connection kit

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Discover the BesterMIG 200-S Inverter, a technological innovation that will radically change your approach to welding. Synergy technology transforms welding by automatically adjusting parameters . With Synergy, the difficulties of determining the ideal current, wire feed speed and correct material thickness are a thing of the past. This adaptive technology assists your welding needs, ensuring remarkable results with minimal effort. By reducing the margin for error, Synergy offers high quality welds with reduced costs. Increase your efficiency and productivity with automatic adjustments that save time and facilitate the welding process. Portable and compact multi-process equipment: MIG/MAG, FCAW, MMA and TIG Lift. Equipped with SYNERGY based on automatic selection of welding parameters Perfect solution for hobbyists and DIY enthusiasts: makes welding faster and more effective

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

The Bester 215MP represents the latest generation of multiprocess machines. Compact, single-phase, based on state-of-the-art inverters. They can be used in many different applications and can be easily moved around the premises or transported to any location effortlessly. These units can be powered from the mains or by generators. Suitable for use with large coil wire (300mm or 200mm). This is a Ready-Pack that contains a 4m MIG gun, earth cable with clamp, gas hose and 0.8-1.0 solid wire rolls. Equipped with wheels and shelf for a gas cylinder. Excellent choice for MIG, TIG lift and MMA welding Compact and robust single-phase inverter Large digital screens and friendly user interface Suitable for use with generators Easy polarity change what is included MIG Gun (4m) Earth cable (3m) Gas hose (2m) Rolls for solid wire 0.6-0.8-1.0 USB with user manual

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

TIG welding machine that combines robust industrial construction with excellent arc . Excellent arc performance - perfect HF ignition, stable, focused and fast arc (for pulsed and non-pulsed arc). Simple control panel - full control, easy configuration. Energy efficiency - PFC circuit, high efficiency, green mode. Portable - Small, lightweight PFC, 16A protection, 100m input cable, prepared for generator.

Request for a quote

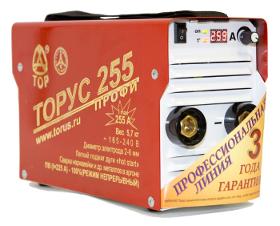

COMPANY TOR

Russia

The VIKING TIG 315 AC / DC PRO argon-arc welding machine is a one-piece structure, designed for power supply from a three-phase 380 V network and produces 315 A at a load of 60%. Special software functions significantly increase the performance factor of the device: HOT-START, ARC-FORCE, ANTI-STICK functions. Specifications: Voltage: V380 Max power: kW5.5 Max current: A315 Operating mode: DC/AC Product class: Professional Burner operating mode: 2-stroke / 4-stroke Pulse mode: yes Availability of the button for saving the selected parameters “MEMORY”, allows you to program 10 parameters for each welding mode (AC/DC). PULSE welding mode is a pulsed consumable-electrode welding (Possibility to use both direct current (DC) and alternative (AC). Waveform selection function (available in AC mode). Dot welding mode 2T and 4T. Adjusting of smooth drop of the terminating current. Adjustable inductance.

Request for a quote

COMPANY TOR

Russia

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quote

ARSILAC

France

316 stainless steel tank Model SCL1000 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Stainless steel handle for movement 4 wheels Ø 200 mm Manhole diameter 400 mm Lid with quick lever closure with EPDM seal Total drain with 40 MACON stainless steel ball valve PVC relief valve Nameplate

Request for a quote

ARSILAC

France

304 stainless steel tank COR700D Model Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 1.5 mm Automated TIG welding process Plastic handle for displacement 3 wheels diam. 100 mm Stainless steel dust cover Total drain with 40 Macon stainless steel ball valve Nameplate

Request for a quote

ARSILAC

France

304 stainless steel tank Model SCL1250 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Stainless steel handle for movement 4 wheels Ø 200 mm Manhole diameter 400 mm Lid with quick lever closure with EPDM seal Total drain with 40 MACON stainless steel ball valve PVC relief valve Nameplate

Request for a quote

ARSILAC

France

304 stainless steel tank Model SBP1250 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Hot galvanized steel chassis Chassis graspable by forklift and pallet truck Manhole diameter 400 mm Lid with quick lever closure with EPDM seal Total drain with stainless steel ball valve 40 MACON PVC discharge valve Nameplate

Request for a quote

ARSILAC

France

304 stainless steel tank Model SBPM1250 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Hot galvanized steel chassis Chassis graspable by forklift and pallet truck Hole for the agitator included Ø 120 mm (the agitator is optional) Lid with handle for semi opening Total drain with 51 SMS stainless steel ball valve nameplate

Request for a quote

ARSILAC

France

304 stainless steel tank Model MTLM1250 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Hole for the agitator included Ø 120 mm (the agitator is optional) Lid with handle for semi opening Total drain with 51 SMS stainless steel ball valve 4 welded stainless steel feet nameplate

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARSILAC

France

304 stainless steel tank Model SCL750 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Stainless steel handle for movement 4 wheels Ø 200 mm Manhole diameter 400 mm Lid with quick lever closure with EPDM seal Total drain with 40 Macon stainless steel ball valve PVC relief valve Nameplate

Request for a quote

ARSILAC

France

304 stainless steel tank Model SBPM750 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Hot galvanized steel chassis Chassis graspable by forklift and pallet truck Hole for the agitator included Ø 120 mm (the agitator is optional) Lid with handle for semi opening Total drain with 51 SMS stainless steel ball valve Nameplate

Request for a quote

ARSILAC

France

Cold Rolled Stainless Steel Tank Brushed exterior finish Interior finish BA Pickled and passivated welds Cold stamped bottoms with optimized profile thickness 2 mm Automated TIG welding process Hole for agitator included Ø 120 mm (optional agitator) Lid with handle for semi opening Total drain with stainless steel ball valve 51 SMS 4 stainless steel welded feet Name plate

Request for a quote

ARSILAC

France

304 stainless steel tank COR200D model Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 1.5 mm Automated TIG welding processa Plastic handle for displacement 3 wheels Ø 100 mm Stainless steel dust cover Total drain with 40 MACON stainless steel ball valve Nameplate

Request for a quote

ARSILAC

France

304 stainless steel tank Model COR130D Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 1.5 mm Automated TIG welding process Plastic handle for displacement 3 wheels diam. 100 mm Stainless steel dust cover Total drain with 40 Macon stainless steel ball valve Nameplate

Request for a quote

ARSILAC

France

Model COR330D 304 stainless steel tank Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 1.5 mm Automated TIG welding process Plastic handle for displacement 3 wheels Ø 100 mm Stainless steel dust cover Total drain with 40 Macon stainless steel ball valve Nameplate

Request for a quote

ARSILAC

France

304 stainless steel tank Model MTLM750 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Hole for the agitator included Ø 120 mm (the agitator is optional) Lid with handle for semi opening Total drain with 51 SMS stainless steel ball valve 4 welded stainless steel feet Nameplate

Request for a quote

ARSILAC

France

316 stainless steel tank Model SCL750 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Stainless steel handle for movement 4 wheels Ø 200 mm Manhole diameter 400 mm Lid with quick lever closure with EPDM seal Total drain with stainless steel ball valve SMS 51 MALE PVC relief valve Nameplate

Request for a quote

ARSILAC

France

304 stainless steel tank Modèle MTLM1000 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Hole for the agitator included Ø 120 mm (the agitator is optional) Lid with handle for semi opening Total drain with 51 SMS stainless steel ball valve 4 welded stainless steel feet nameplate

Request for a quote

ARSILAC

France

Model SBPA1000D Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 1.5 mm Automated TIG welding process Hot galvanized steel chassis Chassis graspable by forklift and pallet truck Complete pneumatic float Total drain with 40 MACON stainless steel ball valve Nameplate

Request for a quote

ARSILAC

France

316 stainless steel tank Model SCL1250 Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Stainless steel handle for moving 4 wheels Ø 200 mm Manhole diameter 400 mm Lid with quick closing lever with EPDM gasket Total emptying with stainless steel ball valve 40 MACON PVC discharge valve Identification plate

Request for a quote

ARSILAC

France

316 stainless steel tank Model SBPM1250 R Cold rolled stainless steel tank Brushed exterior finish BA interior finish Pickled and passivated welds Cold stamped bottoms with optimized profile, thickness 2 mm Automated TIG welding process Hot galvanized steel chassis Chassis graspable by forklift and pallet truck Double wall height 900 mm (3/4 "M. GAS inlet / outlet) Hole for the agitator included Ø 120 mm (the agitator is optional) Lid with handle for semi opening Total drain with 51 SMS stainless steel ball valve Nameplate

Request for a quoteResults for

Tig welding - Import exportNumber of results

35 ProductsCountries

Company type