- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel-forming

Results for

Steel-forming - Import export

NORELEM FRANCE

France

Shrink disc to connect a hollow hub to a shaft. They are mounted on the OD of the hub and generate pressure on the hub wall by reducing the ID with wedgeformed rings, creating a press fit between the hub and shaft. They are suitable for static, dynamic and shock loads. for extremely high torques no axial shaft/hub offset when assembling selfcentring The version 23380014072 has high tensile ISO 4762 screws. Assembly Remove existing transportation locks. Clean and lightly oil shaft, internal and external hub diameters. Do not use MoS2 or grease. Slide shrink disc onto hub. Then slide unit (shrink disc/hub) onto shaft and position correctly. Gently tighten clamping screws one after the other by hand. Then use a torque wrench to tighten the clamping screws crosswise in several increments to the defined tightening torque MS. 1st increment approx. 33% MS 2nd increment approx. 66% MS

Request for a quote

NORELEM FRANCE

France

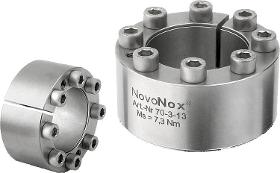

Coupling stainless steel 1.4057. Screws stainless steel 1.4301. For applications that require a small construction volume and low surface pressure. The keyless locking coupling can be fully recessed in a hub connection. for shaft diameters 6 20 mm suitable for hubs with low wall thickness minimum axial offset possible selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

1.4401 stainless steel, similar to DIN 39. Grip suitable for DIN 950 handwheels.

Request for a quote

NORELEM FRANCE

France

Form C and F: Ball steel, ball seat high-carbon steel. Form G and J: Ball high-carbon steel, ball seat steel. Version: Form C and F: Ball hardened and black oxidised, ball seat phosphated. Form G and J: Ball phosphated, ball seat hardened and black oxidised. Note: The self-aligning pads serve as stops, rests and thrust pads in fixture construction. The seating face returns to the start position when the load is removed. Ball secured against rotation. Drawing reference: Form C: male thread, flattened ball, smooth Form F: male thread, flattened ball, diamond grip Form G: press fit, flattened ball, smooth Form J: press fit, flattened ball, diamond grip

Request for a quote

NORELEM FRANCE

France

Body tempered, black oxidised. Ball hardened, bright. Inserts: Form C, F hardened, black oxidised. Form M with carbide serrations, black oxidised. Form K white. Form E hardened, bright. Form O diamond impregnated surface comparable to 100 grade abrasive grit. Form P polyurethane surface, hardness 60 Shore. Note: Self-aligning pads are used to support and clamp unmachined and machined workpieces. In addition, they serve as stops, supports and thrust pads in fixtures and toolmaking. The ball can be removed from the housing by applying light pressure to the socket head screw. Ball secured against rotation. Advantages: Highly cost-effective as inserts can be exchanged. The built-in O-ring holds the ball in place and keeps dirt and foreign particles out, ensuring uniform movement. Drawing reference: Form C: flattened steel insert, smooth Form E: flattened stainless steel insert, smooth Form F: gripper face Form K: flattened POM insert, smooth

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Material: Housing thick steel plate. Tyres steel-wire reinforced elastic solid rubber. Wheel body welded steel. Version: Housing press formed. Reinforced fork, base plate and centre pin. Double ball bearing with hardened shells in the castor head. Precision ball bearings in the wheels. Note: These castors are particularly impact and shock proof and assure a high service life. Wheel axle bolted.

Request for a quote

EUROPONTEX IMPORTAÇÂO & EXPORTAÇÂO

Portugal

- Wide range of steel grades: structural, cold forming, HSLA, etc. - In coils or cut-to-length - Standard os curtomized sizes

Request for a quote

VIRMER

Netherlands

WATTSAN 1325 BASIC fiber laser machine is an economical and practical machine for cutting thin sheet metal. The metal cutting machine works with stainless and carbon steel, copper, aluminum, titanium and other materials. This machine is often purchased for manufacture, such as aviation, astronautics and mechanical engineering. We can install Maxphotonics / Raycus / IPG fiber laser emitter for choice. The main advantage of a fiber laser over a gas laser is its high speed and accuracy of operation, as well as durability: the life of the ignition unit is 100,000 hours, i.e. years of continuous operation. The machine has a working table 1300x2500 mm. WATTSAN 1325 BASIC laser machine is a high-precision device with a reliable control system. It has a high-quality fiber laser emitter. Of course, such a device will last a long time, because the declared service life of the frame is 20 years.

Request for a quote

VIRMER

Netherlands

Fiber metal cutting machine WATTSAN 1325 TABLECHANGE is a large and high-precision machine for cutting stainless and carbon steel, copper, aluminum, galvanized plates and other materials. On this machine, it is possible to install emitters of the following powers: 300/500/750/1000 Watts, and from 1500-5000 Watts with a protective cabin. One of the main advantages of all fiber lasers is durability: the life of the ignition unit reaches 100 000 hours. And this is about 10 years of continuous work. The manufacturer also claims that the bed of this machine can last 20 years. There are two options for the working field for this machine: 1300x2500 mm and 1500x3000 mm (1530 TABLECHANGE). For smaller workpieces, the 1300x2500 mm option is suitable; for industrial production, it is recommended to purchase a larger working area. If you have any doubts about the choice of the working field, please contact our specialists for advice.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 ROTATORY has a rotary device for cutting cylindrical products. This machine is purchased for cutting steel tubes, galvanized and stainless steel, aluminum, brass and other materials. The machine is most often used in aviation, aerospace and mechanical engineering, as well as for the manufacture of auto parts, advertising products and household appliances. You can install a radiator of any power: 300/500/750/1000/1500/2000/3000/4000/5000 Watts. Important: the machine is equipped with a protective cabin with a power of 1000 Watts. Optional fiber laser emitter: Max / Raycus / IPG. Each of them is distinguished by high accuracy and speed of work, durability, but there are also differences. IPG is considered a premium model, it gives the best result and speed. The service life of the emitter ignition unit is about 100 000 hours. The protective glass for the lens, which must be changed at least once a month. The lens itself needs to be renewed approximately once a year.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 ROTATORY CABINE is a powerful fiber laser machine, also known as a tube cutter. The device is equipped with a protective cabin for safe operation, as well as a rotary device. The rotary device takes the capabilities of your equipment to a whole new level. You can use the metal cutter like a regular cutter, and in a few minutes switch to the task of cutting tubes. The protective cabin is installed on machines from 1000 watts. This ensures the safety of the laser cutting operator, as well as minimizes the dangers of external influences. The machine is equipped with a fiber optic emitter: Max or Raycus or IPG. Such an emitter will last up to 100 000 hours of the most intensive work. If we talk about the intensity of work — the stand is weighted, crushes vibrations and will last 20 years, according to the manufacturer's information.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 TABLECHANGE is a high precision fiber laser cutting machine. It is equipped with an automatic change table. This design allows you to quickly change sheet metal while another workpiece is being cut. Such a system saves time and money for its owners. Such a machine has long been used in aircraft construction, mechanical engineering, light industry and medical equipment. The machine is equipped with a laser solid-state emitter to choose from: Max / Raycus / IPG. All three have proven themselves: Max is standard, Raycus is more expensive and better, and IPG is considered a premium series. All three types of emitters have a resource of about 100,000 hours. The automatic change table has a size of 1500×3000 mm for metal. The bed is made with a margin of safety, and the heavy weight dampens vibrations. Vibration mounts can be installed for added stability.

Request for a quote

PROSAW LIMITED

United Kingdom

ASM model is made of cast iron construction. ASM machines are combining the user friendly features, quality and best prices as an economical model. ASM - 3 Rolls Asymetical Plate Roll Machine Standard Details Body is made of cast iron construction Central rollers powered with electric motor, gearbox and gear drive Cone bending device Self brake main motor Upper roll is opanable by side Lower roll and back roll are with hand wheels up & down adjustable. Separate eletric control panel with foot pedal Suitable for CE, ISO 9001-2008, TSEK and TURQUM certificates ASM - 3 Rolls Asymetical Plate Roll Machine Optional Features Induction hardened rolls. Back roll with motor. Digital display.

Request for a quote

PROSAW LIMITED

United Kingdom

This Geka Hydracrop 110S is a versatile and economic universal steelworker with 2 independent hydraulic cylinders, 2 areas and 5 workstations. It is suitable for punching profiles and for mounting special equipment. It benefits from a greater speed backed by a powerful hydraulic unit. Geka Hydracrop 110S Standard Details Machines driven by two cylinders 5 work stations, fitted with tools for L, shearing, round and square bars, rectangular notching and punching Quick change punch Flat bar shearing table with adjustable guides 2 simultaneous work stations Greater speed backed by a powerful hydraulic unit Special equipment for approaching at reduced pressure and slow speed Precision punching table with X & Y measuring stops Precision notching table with X & Y measuring stops Ready for production pack comprising: One meter "touch & cut" length stop with fine adjusting Lamp for enhanced vision of cutting zones 10 sets of round punches and dies

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Stainless steel Form: sheet Material: 1.4404 (X2CrNiMo17-12-2) Manufacturing method: cold-rolled, 2J Surface finish: brushed Ground sites: on one side Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 1.5 - 2 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quoteResults for

Steel-forming - Import exportNumber of results

16 ProductsCompany type