- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- polyurethane foams

Results for

Polyurethane foams - Import export

BABYBRANDS

Greece

Soft hypoallergenic pillow with memory foam Made from luxurious cotton velvet Designed for babies aged 0-12 months Removable pillow case with zipper Ventilated memory foam padding for better airflow and less moisture retention Luxurious embroidered detail Cover: 75% cotton 25% polyester Filling: 100% polyurethane memory foam Luxury gift box

Request for a quote

BABYBRANDS

Greece

Soft hypoallergenic pillow with memory foam Made from luxurious cotton velvet Designed for babies aged 0-12 months Removable pillow case with zipper Ventilated memory foam padding for better airflow and less moisture retention Luxurious embroidered detail Cover: 75% cotton 25% polyester Filling: 100% polyurethane memory foam Luxury gift box

Request for a quote

BABYBRANDS

Greece

Soft hypoallergenic pillow with memory foam Made from luxurious cotton velvet Designed for babies aged 0-12 months Removable pillow case with zipper Ventilated memory foam padding for better airflow and less moisture retention Luxurious embroidered detail Cover: 75% cotton 25% polyester Filling: 100% polyurethane memory foam Luxury gift box

Request for a quote

POFI-ENGINEERING

Luxembourg

Polyurethane foam is primarily a cellular plastic. The properties of this die depends mainly on two factors, the structure and composition. The cell structure is formed by the action of blowing agents. The more the structure is fine and homogeneous, the more mechanical properties of the polyurethane foam is good. The chemical composition also between largely in its mechanical strength. A homogeneous mixture stoichiometric gives the polyurethane foam its optimum mechanical properties. Nucleation (air, CO2 or nitrogen) enters the like using a part of the mechanical expansion. When physical agents are used to form the cells, the gas phase of foamed plastic is chemically identical to that of the blowing agent. This technique has encountered difficulties of implementation, recently solved by adding the function of the miscibility of gas into a liquid through a set of changes associated with a system for mixing and homogenisation pressures of high performance. The direct effects of...

Request for a quote

POFI-ENGINEERING

Luxembourg

Process improvements: With the various changes in standards and safe polyurethane foams are becoming increasingly difficult to implement and require a perfect mastery of the production parameters. Temperature is one of the parameter. Currently it is mainly measured and controlled at low pressure, which is not the optimal solution because the components move in after the high pressure pump and function of viscosity, flow, outside temperature, pressure and drop pressure in the circuit products can not arrive at the mixing head at a uniform temperature and even. The heat exchanger provides heat for the first time to master the temperature high pressure side to help balance and well master the temperature with high accuracy. Do not hesitate to contact us for more information .

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POFI-ENGINEERING

Luxembourg

Dispergator for sandwich panel production lines Mixing concept Because of changes in regulations on additives and the complexity of for-mulations, items in the Polyol blend viscosities were varied and are very difficult miscible or even immiscible. The result is a foam very difficult to implement, surfaces in contact with the plate full of bubbles, adhesion problems, shrinkage problems, bubbles, … To circumvent the lack of miscibility of the components we have developed two elements allowing a dispersion of additives and the gas into very small particles homogenously distributed in the Polyol. Therefore, when the Polyol is mixed in the mixing-head with Isocyanate, additives are much more reactive and there is no concentration of gas or random foaming agents that create bubbles surface states or « potato fields. ». The disperser is to this day an essential element of the production units of polyurethane foams and have a great effect on PIR. It is available as low pressure (air...

Request for a quote

POFI-ENGINEERING

Luxembourg

Benefits of the dispenser: The quality of the polyurethane foam for sandwich panels produced continuously is strongly dependent on the control of the wave. If the speed of the line is not well controlled and if the contact point of the wave with the top of the facing is not well positioned the mechanical properties of the produced panel decrease considerably. The spreading system mostly used mostly used at present is the “Poker”, a rake which oscillates in different speeds from left to right and from right to left of the panel. We settle generally a covering around 60 % on the return to the rake. This system contains numerous inconveniences: the distribution is very difficult to make homogeneous, make it cover the foam tends to crush cells in formation of the first passage and the wave is not uniform, thus difficult to adjust. The novelty is the fix foam dispenser, it allows of landing all these problems. The foam is put down on the lower facing in a uniform way and allows of...

Request for a quote

POFI-ENGINEERING

Luxembourg

Nucleation unit for continuous production lines POFI-Engineering concept: Foam polyurethane is before a whole alveolar plastic. The properties of this matrix depend mainly on two factors, the structure and the composition. The structure of the cells is carried out by the action of the inflating agents. More the structure is fine and homogeneous, more the mechanical characteristics of foam polyurethane are good. The chemical composition between also mainly in its mechanical resistance. A homogeneous and stoichiometric mixture confers on foam polyurethane its optimal mechanical characteristics. Nucleation (air, nitrogen or CO2) enters the part still little used mechanical expansion. When physical agents are used to form the cells, the gas phase of the alveolar plastic is chemically identical to that of the inflating agent. This technique had problems of implementation, recently solved by the addition of the function of miscibility of gases in a liquid via a whole of variations of...

Request for a quote

BAUFENS

Bosnia and Herzegovina

Akfix serves to his customers a wide product range of: Adhesives & Glues Sealants & Silicones PU Foams Technical Aerosols Waterproofing and Heat Insulation products Automotive After Care Products Industrial Products Disenfectants With its proliferative know-how and knowledge, Akfix comes up to be an ideal MASTER OF SOLUTIONS, who is a real professional and international player in polyurethane foam and sealants market, development and suply. It CREATES PERMANENT SOLUTIONS to support and complete professional building and construction companies in all their operations.

Request for a quote

DISTRIBUCIONES JULMARSA S.L.

Spain

Polyurethane foam. Allows you to mask surfaces that require filling to prevent paint from entering the protected area. Main advantages: Excellent adhesion. Resistant to temperatures up to 80º C. Leaves no adhesive residue when removed. Applications: Automotive masking, usually for doors, gas cap, trunk and hood. Standard widths:13mm,17mm(other widths possible)

Request for a quote

CITRIN GLOBAL SRL

Romania

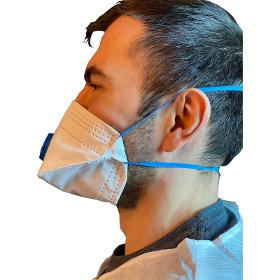

The FFP3 protective respirator effectively filters and blocks up to 98% of 0.3 micron particles. Filtration capacity up to 30 x CMA (Maximum allowable concentration). Multiple layers for increased airway protection. Auxiliary air expiration valve. Fixing the mask comfortably on the face, with polyurethane foam cushions inside

Request for a quote

ARSILAC

France

Reference : 006831 SERAP 145 HL (14 500 liters) TECHNICAL FEATURES - Manufacturer : SERAP - Year : 2019 - Insulated truncated cone-shaped 304 stainless steel tank - Inner tank with sheet metal appearance: Annealed Brilliant (2R) - External vat with sheet metal appearance : -- Dome: polished 320 grain -- Shell: circular polishing fine grain + "Scotch Brite" finish -- Bottom: Cold rolled (2B) - Exchanger characteristics : -- Connection: Ø20x27 Female -- Test pressure: 10 bar -- Maximum working pressure : 6 bar -- Exchange surface area: 10.0 m². - Maximum working pressure in the tank : -0.002 / +0.05 bar - Insulation: polyurethane foam injected on shell, bottom and dome

Request for a quote

PURASOL GMBH

Germany

One- and two-component PU-foams with excellent insulating and adhesive characteristics as nozzle - or dispenser- formulation. Monomer low foams as an innovative and environmental-friendly variation. 2C-Acoustic-foam-systems for automotive industry.

Request for a quoteResults for

Polyurethane foams - Import exportNumber of results

14 ProductsCountries

Company type