- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- panel products

Results for

Panel products - Import export

TECHNIC MACHINES

Turkey

Our PU, PIR and PUF sandwich panel production machines have different capacity and production thickness from 30 mm to 200 mm and also sandwich panel making machine speed from 6 meters/minute to 16 meters/minute with 50 mm sandwich panel thickness production. Our sandwich panel machine lines are the optimum solution in the market with quality and performance matching parameters. Sandwich Panel Production Line Units Roll Decoiler Machine Feeding Unit Film Coating Unit Roll Forming Machine Rolling Conveyor Unit Pre-Heating Foaming Machine Double Belt Pressing Machine Rolling Conveyer Fly Cutting Unit Runout Table Automatic Vacuum Stacker Automatic Packaging Machine Metal raw material can be changed on sandwich panel machines, as aluminium, metal sheet, pre-painted metal sheets etc.

Request for a quote

AKSA ACOUSTIC SOUND INSULATION MATERIALS

Turkey

Different sizes and different perforated wooden panels. Our own production

Request for a quote

AKSA ACOUSTIC SOUND INSULATION MATERIALS

Turkey

You can choose 3d acoustically coated panels from products that can be used to give a decorative look while ensuring 3D wall panel ambient acoustics. The main material as 3D wall panel content has the same values as our other acoustic panel models. With the 3D acoustic panel that can be produced in special sizes and shapes, you can create a room with perfect design with your imagination. The poplaty room with 3D wall panel, music room, studio audio recording room, office, study room, conference room and so on. ideal for acoustic environments.

Request for a quote

APD MAQMASTER

Spain

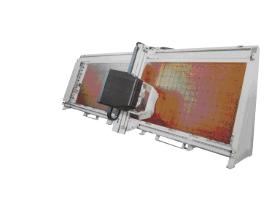

Three, four and five controlled axis configurations Bakelite work surface Extreme versatility to adapt to different materials such as PVC and plexiglass Working ranges: 3500×1600 – 2000 mm, 5000×1600 – 2000 mm, 6000×1600 – 2000 mm Work areas divided into 6/8/10 vacuum zones, automatically activated by the software according to the dimensions of the processed panels Benefits: Speed and precision in CNC machining of aluminum panels Greater comfort and productivity for operators Significant space savings compared to horizontal machines Versatility to work with a wide range of materials

Request for a quote

TECHNIC MACHINES

Turkey

Our polystyrene extrusion machines have different production capacity and final ps final product solutions so that we can match with customers request. Our polystyrene extruder machines are used for different fields, as polystyrene skirting extruder machine, polystyrene frame extruder machine, polystyrene panel production line, polystyrene rod extruder, polystyrene foam block extrusion line and for other polystyrene extrusion machines. Just contact with us for your request about polystyrene extrusion machine line, we will offer you best solution.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POFI-ENGINEERING

Luxembourg

Dispergator for sandwich panel production lines Mixing concept Because of changes in regulations on additives and the complexity of for-mulations, items in the Polyol blend viscosities were varied and are very difficult miscible or even immiscible. The result is a foam very difficult to implement, surfaces in contact with the plate full of bubbles, adhesion problems, shrinkage problems, bubbles, … To circumvent the lack of miscibility of the components we have developed two elements allowing a dispersion of additives and the gas into very small particles homogenously distributed in the Polyol. Therefore, when the Polyol is mixed in the mixing-head with Isocyanate, additives are much more reactive and there is no concentration of gas or random foaming agents that create bubbles surface states or « potato fields. ». The disperser is to this day an essential element of the production units of polyurethane foams and have a great effect on PIR. It is available as low pressure (air...

Request for a quote

POFI-ENGINEERING

Luxembourg

Concept of the Laser: The conduct of a sandwich panels production line is usually managed by operators, and there is often that there are differences in production function of the operator to control (density, quality, productivity, …). The operator with many different tasks to perform, it also happens that the wave moves without noticing and it results in poor quality panels. The laser serves to measure the distance between the removal of foam and wave, once the distance set by the operator the laser takes over and manages the line speed to maintain a constant position of the wave. If there is a too great a speed correction to achieve the laser warns the operator. The set distance is displayed on a screen and can be stored. It will allow to verify the differences in positioning of the wave function and operators to address potential problems. During production, the operator is released from a spot and will be able to focus on other priorities. This system is compatible with all...

Request for a quote

POFI-ENGINEERING

Luxembourg

Dispergator for sandwich panel production lines Mixing concept Because of changes in regulations on additives and the complexity of for-mulations, items in the Polyol blend viscosities were varied and are very difficult miscible or even immiscible. The result is a foam very difficult to implement, surfaces in contact with the plate full of bubbles, adhesion problems, shrinkage problems, bubbles, … To circumvent the lack of miscibility of the components we have developed two elements allowing a dispersion of additives and the gas into very small particles homogenously distributed in the Polyol. Therefore, when the Polyol is mixed in the mixing-head with Isocyanate, additives are much more reactive and there is no concentration of gas or random foaming agents that create bubbles surface states or « potato fields. ». The disperser is to this day an essential element of the production units of polyurethane foams and have a great effect on PIR. It is available as low pressure (air...

Request for a quote

DOREY

France

The AES1900 is an All in One Automated Finishing Solution. It will quickly and efficiently finish products reducing your finishing bottlenecks. The AES1900 is designed with the capability to weld and grommet single panels or produce product off roll FEATURES, FUNCTIONS & BENEFITS Input table for easy feeding of material for operators Automatic placement of grommets Simple material exit for collecting finished product Adjustable to various lengths and widths for nearly any size product Complete operator interface for product memory, sizing and settings Machine can operate in the following modes Weld only, Grommet only, Weld and Grommet, Weld and Hole Punch

Request for a quote

EACTECH®

Portugal

The filling equipment for delicatessen that combines speed and efficiency The Filler EVC-2000 is the equipment you will want as an ally for filling in delicatessen. Chorizo, fresh sausage, sausage, salami, etc. It combines a 10-fin motor feeding system, reducing losses and preventing stains and bubble formation, while controlling the exact size of the portions. A filling solution for optimal results on your production line. The HF-250 hamburger maker is state-of-the-art equipment to produce a wide range of hamburger shapes and sizes. The mold filling system is automatic, guaranteeing uniformity and quality of the final product. Speed and pressure configured on touch panel Greater efficiency Extra income Touchscreen system Control panel with microprocessor Final product quality guaranteed 100%

Request for a quote

STI GROUP / STI - GUSTAV STABERNACK GMBH

Germany

Flexible modules from black lacquer wooden panels showcase individual product categories from Philips Lighting in hardware stores. If the product line is changed, only the panels need to be changed. To preserve the high-end look, the euro pallet under the POS display is overlaid with black lacquer sheet. The unit is suitable for transport and is delivered fully assembled and wired to retail stores.

Request for a quote

J-FLEX RUBBER PRODUCTS

United Kingdom

Our Vac-Sil® Quality Membranes have been specifically designed for use as vacuum membranes for Solar/P.V. module lamination, plus the forming or thermo-pressing of vinyl foil veneers on furniture woodwork, composites in aerospace, F1 cars, marine, and other general products. We also provide a range of precision components, primarily for use in solar panel production. The range includes laminator vacuum seals, PTFE & Glassfabric belts (Stringer, Release, Vision, Transport etc) and also squeegee edge profiles for screen printing. Listening to our valued customers and their experiences, VAC-SIL® Quality Membranes have been polymer engineered to give users excellent thermal and mechanical properties, with good chemical resistance that leads to optimum service life. Visit our website for further information - advantages, benefits, areas of use, datasheets, faq's and installation instructions.

Request for a quoteResults for

Panel products - Import exportNumber of results

13 ProductsCountries

Company type

Category

- Acoustic panels (2)

- Bottling and filling - machinery and equipment (1)

- Extrusion, plastics - machinery (1)

- Food Processing (1)

- Injection, plastics - machinery (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Metal industrial presses (1)

- Metallurgy - machinery and installations (1)

- Sheets, rubber (1)

- Textiles - Machines & Equipment (1)