- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- panel machining

Results for

Panel machining - Import export

TECHNIC MACHINES

Turkey

Our PU, PIR and PUF sandwich panel production machines have different capacity and production thickness from 30 mm to 200 mm and also sandwich panel making machine speed from 6 meters/minute to 16 meters/minute with 50 mm sandwich panel thickness production. Our sandwich panel machine lines are the optimum solution in the market with quality and performance matching parameters. Sandwich Panel Production Line Units Roll Decoiler Machine Feeding Unit Film Coating Unit Roll Forming Machine Rolling Conveyor Unit Pre-Heating Foaming Machine Double Belt Pressing Machine Rolling Conveyer Fly Cutting Unit Runout Table Automatic Vacuum Stacker Automatic Packaging Machine Metal raw material can be changed on sandwich panel machines, as aluminium, metal sheet, pre-painted metal sheets etc.

Request for a quote

TECHNIC MACHINES

Turkey

Roof panel roll former machine is pretty common almost all countries. Shape of metal roof panel can be different by countries but we provide also different shapes for our customers. Also we can provide different cassette or double layer on our roof panel machine. Roof Panel Roll Forming Machine's Units - Coil Decoiler Machine - Roll Forming Unit - Cutting Shear - Control Panel - Stacking Unit Just contact with us for your request, we will provide the optimum solutions.

Request for a quote

APD MAQMASTER

Spain

X axis (Longitudinal) 2000 mm Y axis (Horizontal) 4000 mm Z axis (Vertical) – without milling 300 mm POSITIONING DISTANCES X axis (Longitudinal) 108m/dK Y axis (Horizontal) 108m/dK Z axis (Vertical) 10.5m/dK SPINDLE 7.5/9kW fan cooled spindle Maximum power 24000 rpm Maximum rotation speed ISO 30 Tool holders Electric fan TOOLS MAGAZINE Automatic umbrella type tool magazine system Maximum number of tools 10 Maximum disc diameter that can be loaded into the magazine system 150 mm Maximum dimensions of tools that can be loaded in the magazine system 140 mm Diameter / 120 mm Length Number of angled heads that can be loaded into the magazine system 2 OPERATIONAL AREA Vacuum table system with automatic zoning Vacuum table tube dimensions 269 mm * 2000 mm Number of externally controlled vacuum modules 7 X axis reference support 1 And axis reference support 4 Automatic tool length measurement Possibility of operation in two stations

Request for a quote

APD MAQMASTER

Spain

X axis (Longitudinal) 2000 mm Y axis (Horizontal) LEPUS II 4000 mm – LEPUS II L 7000 mm Z axis (Vertical) – without milling 200 mm POSITIONING DISTANCES X axis (Longitudinal) 55 m /dK Y axis (Horizontal) 55 m /dK Z axis (Vertical) 15 m /dK SPINDLE Spindle cooled by 4 fans Maximum power 2.2 kW Maximum rotation speed 18000 rpm ER20 tool holder CONTROL UNIT CNC control Remote network connection, data transfer via Ethernet and USB. OPERATIONAL AREA Dust and chip aspiration system Suction areas in independent spaces Externally controlled vacuum tables LAPUS II 6 – LAPUS II L 8 Automatic tool length measurement Possibility of doing double station processing X axis reference support Y axis reference support LEPUS II 4 – LEPUS II L 9 Metal fences closed on three sides that prevent access to the work area

Request for a quote

APD MAQMASTER

Spain

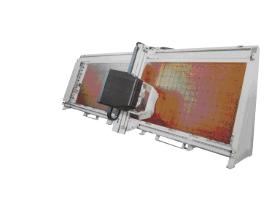

Three, four and five controlled axis configurations Bakelite work surface Extreme versatility to adapt to different materials such as PVC and plexiglass Working ranges: 3500×1600 – 2000 mm, 5000×1600 – 2000 mm, 6000×1600 – 2000 mm Work areas divided into 6/8/10 vacuum zones, automatically activated by the software according to the dimensions of the processed panels Benefits: Speed and precision in CNC machining of aluminum panels Greater comfort and productivity for operators Significant space savings compared to horizontal machines Versatility to work with a wide range of materials

Request for a quote

APD MAQMASTER

Spain

Fixed Bakelite work table: Robust and resistant, ideal for demanding jobs. Closed table technology: Allows both suction cup and nesting operations, optimizing your workflow. Controlled axes: Three, four or five axes for greater precision and flexibility in your projects. Suitable for any type of processing: Perfect for cutting, milling, drilling and much more. Ideal for working with panels Horizontal CNC machines with a closed table are especially recommended for those working with wooden panels, as the closed top technology allows for safe and precise clamping using suction cups or sockets.

Request for a quote

TECHNIC MACHINES

Turkey

Complete turnkey roll forming machine line according to the finished final product with all necessary equipment, such as uncoiler, feeder, roll former, hydraulic or eccentric presses, stacking unit, etc. We offer standard models of roll forming machines as well as specific models according to the final product requirements of our customers. Some of our standard roll forming machine models are: • Warehouse racks and shelves • Market racks and shelves • Building and construction • C, U, Z, and Sigma (track and stud) • Guardrail • Roll-up door forming machine • Roof panel forming machine • Standing seam • Wall panel • Drywall and plasterboard • Snap lock • Cable tray • Scaffolding Just contact us for any roll forming machine you need, and we will find the optimal solution.

Request for a quote

TECHNIC MACHINES

Turkey

As Technic Machines, we supply all kind of roll forming machines. We have in our portfolio some standard roll former machine lines but also we provide customs solutions for our customers Roll former machine is pretty common machine in metal industry and each work can have small differences because of the local market demand on roll forming shape. We provide exact solution for our customers with different width, thicknesses and shapes of roll forming. We supply for our customers as standard roll form machine, Customs Roll Former Machine Glazed and Step Tile Making Machine Roof Panel Roll Forming Machine Trapezoidal Sheet Roll Forming Machine Corrugated Sheet Roll Forming Machine Rolling Shutter Roll Former Machine Drywall and Gypsum Channel Making Machine Just contact with us for your other roll forming machine request, we will provide customs solution according to your roll former machine research.

Request for a quote

TECHNIC MACHINES

Turkey

Our polystyrene extrusion machines have different production capacity and final ps final product solutions so that we can match with customers request. Our polystyrene extruder machines are used for different fields, as polystyrene skirting extruder machine, polystyrene frame extruder machine, polystyrene panel production line, polystyrene rod extruder, polystyrene foam block extrusion line and for other polystyrene extrusion machines. Just contact with us for your request about polystyrene extrusion machine line, we will offer you best solution.

Request for a quote

COLORICIO.SRL

Romania

Extruded Aluminium is used also in countless applications. Functional or fully machined control panels Ready to install electronic enclosures

Request for a quote

FRIMO GROUP GMBH

Germany

Good ergonomics and optimal component accessibility Milling can be used to not only create highly complex component geometries, but also to achieve precise cutting depths. It is often used in combination with punching operations to produce component variations or small quantities, such as of instrument panels, center consoles or door panels. FRIMO FlexTrim milling machines have been specially developed to process complex 3-D plastic components. The newest generation of FlexTrim milling machines offers an attractive price/performance ratio. The new rotary table and product fixture concept ensures excellent ergonomic conditions for the operator and optimal component access for the milling robots. The use of multiple product fixtures per station reduces the number of necessary changes, thereby increasing productivity. Through the use of new milling technology with optimized chips, an effectiveness ratio of up to 95 % is possible with appropriate material combinations.

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We can supply various types of EPS-XPS foam decoration machines - 2D/3D CNC cutting machines, thermopress or hot press machines, CNC routers, mortar mixing and coating machines and panel printers. For more information about our products and services, please visit www.estechtic.net. You can send your inquiries to fr@estechtic.net.

Request for a quote

KGA ENCLOSURES LTD

United Kingdom

Product Features: • 18 gauge steel base for extra strength. • Easy to machine - aluminium top panels are 0.064" thick aluminium. • Sides include vertical rows of ventilation. • Sold pre-assembled with a two tone grey powder paint finish (base is dark satin grey, slope top is smooth light grey). • Comes with four self-adhesive rubber feet and required hardware.

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

High speed, needle feed lockstitch machines NF 3901 AUT – All-in- one high speed, needl feed lockstitch machine with fully automatic lubrication, thread trimmer and back tack. Motor, control box and control panel are integrated in the machine. The bobbin winder is built-in the machine head as well. Presser foot lifter is available as an option. NF 3901 LH-AUT – Same as above, but equipped with large hook. Product NF 3901 DD, NF 3901 AUT, NF 3901 LH-DD, NF 3901 LH-AUT Table Top No Table Top, Special table top D (115 x 55 x 4 cm) if sold with PFL, Table grey C 350 AUT (120x55x4 cm), Table Top D 105x55x4 cm Stands No Stand, Stand C (China), Stand K (912 mm), Stand K short (667 mm), Stand Z Option AK 3900 presser foot lifter (only for AUT), No option

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

High speed, needle feed lockstitch machines NF 3901 DD – High speed, direct drive needle feed lockstitch machine with fully automatic lubrication. Equipped with built in motor and a separate control box. The bobbin winder is built in the machine head. NF 3901 LH-DD – Same as above, but equipped with large hook. NF 3901 AUT – All in one, high speed, direct drive needle feed lockstitch machine with thread trimmer and automatic back tack. The machine has fully automatic lubrication and motor, control box and control panel are integrated in the machine. Presser foot lift is available as an option. NF 3901 LH-AUT – Same as above, but equipped with large hook. High speed, needle feed lockstitch machines NF 3901 DD – High speed, direct drive needle feed lockstitch machine with fully automatic lubrication. Equipped with built in motor and a separate control box. The bobbin winder is built in the machine head. NF 3901 LH-DD – Same as above, but equipped with large hook. NF 3901 AUT – All...

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

High speed, single needle lockstitch machine 3900 DD – High speed, single needle lockstitch machine. This machine has fully automatic lubrication and the motor and control box are integrated in the machine. Max. stitch length is 4 mm. Max. machine speed: 5000 spm. 3900 LH-DD – Same as above, however equipped with large hook. 3900 AUT – All-in-one high-speed, single needle lockstitch machine. This machine has fully automatic lubrication and motor, control box and panel are integrated in the machine. The machine is equipped with presser foot lifter. The bobbin winder is built-in the machine head. 3900 LH-AUT – Same as above, however equipped with large hook. High speed, single needle lockstitch machine 3900 DD – High speed, single needle lockstitch machine. This machine has fully automatic lubrication and the motor and control box are integrated in the machine. Max. stitch length is 4 mm. Max. machine speed: 5000 spm. 3900 LH-DD – Same as above, however equipped with large...

Request for a quote

PRECITOOLS SRLS

Italy

We present semi-automatic grinding machine F-Grinder to sharp punching tools (punches and dies) for various models and systems of punching presses: Trumpf Trumatic, Trumpf Trupunch, Boschert, Haco, Pullmax , Amada, Finn-Power, Prima-Power, Durma, Schiavi, LVD, Strippit, Danobat, Yawei, Nisshinbo, Euromac, Baykal, FIM, Murata Muratec, Rainer, MVD, Tailift, SimasV, Yangli, Peliant, SNK, Pullmax, Hesse-Maschinen, Ermaksan, Dener, ITEK, SMD etc. Grinding of punches and dies with height up to 230 mm, diameter of 180 mm. Control panel SIEMENS TOUCH. Machine is with coolant, closed grinding area, 3-jaw universal chuck, no any additional adapters are needed. Table tilt to make the angle grinding. Please contact by E-mail for the detailed offer. This is the advertisement, not the official offer. All the mentioned brands and trademarks pointed just for the information and are the property of their respective owners.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Panel machining - Import exportNumber of results

17 ProductsCompany type

Category

- Machines for the manufacture of PVC and Aluminium Doors and Windows (4)

- Rolling mills - machinery and installations (2)

- Control boxes - electric (1)

- Electric cables (1)

- Extrusion, plastics - machinery (1)

- Grinding - machine tools (1)

- Metal engraving - machine tools (1)

- Metallurgy - machinery and installations (1)

- Restoration and renovation - contractors (1)