- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packing machines for packing

Results for

Packing machines for packing - Import export

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 20 form, fill and seal machine enables the production of bags made of polyethylene film from a flat film roll. The film can be neutral or coloured, with continuous printing or centred printing with print mark. The design of the machine and the low loading height allow ergonomic adaptation to a manual feeding station or easy connection to a feeding unit, such as an automatic counter, an automatic weighing system, an automatic assembly machine, an injection moulding machine, a conveyor belt or similar.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 06 form fill and seal machine uses standard polyethylene, biodegradable oxo sleeves or biodegradable sleeves (starch-based). The TEC 06 is particularly suitable for the production of display bags. The sealing head simultaneously performs the top seal of the pouch and the bottom seal of the next pouch, a cut is made between the two welds, and at the same time a pre-cut is made across one thickness of the sleeve to form a "kangaroo pocket" that allows the pouch to be filled. As this pocket is firmly connected to the spool, slippage is not possible, so that the weld seams subsequently run perfectly parallel. Due to the functionality and quality of its equipment, the TEC 06 is a very reliable machine that consumes few wearing parts.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 55 was developed to meet the demand for high throughput rates. Flexibility, easy maintenance, simple settings, synchronisation with the infeed systems, flexibility and quiet operation were the priorities in the development of this machine. The machine achieves an output of up to 80 bags / minute. The most common options and accessories: - Hanger hole - Precutter for easy opening - Jogger to level the products before closing the bag - Bag identification system: - Marking by transfer to the film - Label printer - Inkjet printer - Flap for heavy products - Cell for pre-printed film - Drive by suction belts - Synchronisation with: - Multihead weigher - Auger filler - Cup doser - All other machines - Suction plate for changing the film roll

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Standard elements : - Robust frame in grey or white lacquered steel - Conformator tube - Welding jaw with heating rod (hard chrome plated) with constant temperature controlled by temperature controllers with digital display - Drive of the film by belt - Motorisation of the unwinding of the roll - Control generated by SPS - Touch screen display - Programme memory (weight, length of bags...) - Fine detection of the reel - Translucent mapping Material according to current EC standards. Films that can be used: polypropylene, composite, aluminium, barrier, polyethylene.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Tecnimodern's slanted or vertical form fill and seal machines with very low loading height allow the production of polyethylene or polypropylene film bags from a flat film roll. The film can be neutral or coloured, with continuous printing or centred with print mark. These TEC30 packaging machines have the advantage that they can be equipped with either a thermal sealing system for heat-sealed films or an impulse sealing system for polyethylene films, depending on requirements. To meet the need for all types of packaging, feeding and product shapes, we offer various automatic feeding systems, such as: - Counting with vibrating or centrifugal trays - Weighing with linear scales - Dosing by augers or volumetric feeders

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CUPASO DEUTSCHLAND GMBH

Germany

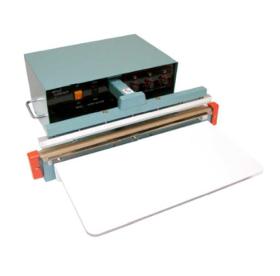

Electromagnetic sealing jaw type MS...IP for welding and sealing bags: - From PE - From PP - From soft PVC or polyamide Features: This sealing jaw has: - Adjustable welding time - Adjustable cooling time - Adjustable cycle time The jaw is controlled by an electric foot pedal.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Continuous sealers type SCV and SCH, to seal bags made of PE, PP, soft PVC, polyamide paper, aluminium or cardboard tabs as they pass through the sealer. - Adjustable speed from 0 to 12 m/minute - Temperature adjustable from 0°C to 400°C. - Width of the weld: 10 mm - Maximum weight on conveyor belt: 10 kg - Optional: bag counter - hot stamping on the weld seam

Request for a quote

THOMSON MACHINERY BV

Netherlands

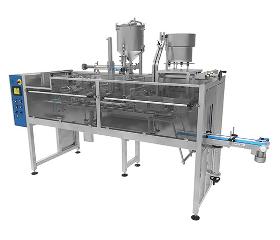

MODEL KY-2 POWER 0.85KW VOLTAGE 380V/50Hz FILLING CAPACITY 100ML-500ML PRODUCE CAPACITY 1500BPH AIR PREESURE 0.5-0.75MPA WEIGHT 800KGS SIZE 1500*1000*2100MM

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

The Invertec 150S is suitable for a variety of applications and working environments. Its design was focused on providing excellent welding and starting behavior in a robust and reliable package. It is equipped with a unique set of features and capabilities to ensure perfect welding for your application. Robust and robust on the one hand, portable on the other, the Invertec 150S is light and easy to handle in any situation. Rugged Design – Unique rubber corners, metal casing and control buttons to withstand harsh environmental conditions. Premium Arch – Lincoln 's advanced technology and know-how guarantee performance every time. Power Surplus – Additional power for superior arc control. Soft and Crisp Mode – Selectable arc modes for different electrode types Self-adaptive arc force – For a stable arc with low spatter levels as standard. Integrated “Hot Start” for stable arc with lower splash level. Long cables: primary power extension cables up to 60 m.

Request for a quote

NHM LIMITED

Ukraine

SPECIFICATION PRODUCTIVITY1500 pouches/hour FILLING RANGE200-1000 ml POWER SUPPLY, MAX220 V, 50 Hz COMPRESSED AIR PRESSURE5 kg/cm2 AIR CONSUMPTION~ 0.2 m3/hour @4 bar PACKAGING MATERIAL1/2/3-layered polyethylene film with black internal layer; thickness – 70-90 microns, width – 320 mm FILLING ACCURACY± 0,5-1% [depending upon bulk density of product, constant product availability in the product tank (for liquids), proper maintenance] OVERALL DIMENSIONS , (WxLxH)670 x 790 x 2570 mm WEIGHT, NET~ 450 kg MACHINE CONSTRUCTION All components are mounted on a single frame. All parts in contact with the product are made from stainless steel AISI 304 . The exterior panels are made of stainless steel AISI 202. Mechanical drive. Protective and hygienic front door. Basic Elements: Film unwinding is provided by rubberized shaft with electric drive and operated by inductive sensors Ultra-violet lamp for film sterilization Liquid Filler CIP connector

Request for a quote

NHM LIMITED

Ukraine

TECHNICAL SPECIFICATIONS SPECIFICATION PRODUCTIVITY2100-3000 pouches/hour FILLING RANGE200-1000 ml POWER SUPPLY, MAX1,5 kW, 380 V, 50 Hz COMPRESSED AIR PRESSURE6 kg/cm2 AIR CONSUMPTION~ 30 m3/hour WATER CONSUMPTIONdoes not require water PACKAGING MATERIAL1/2/3-layered polyethylene film with black internal layer; thickness – 60-90 microns, width – 320 or 325 mm; Outer diameter of roll – up to 400 mm FILLING ACCURACY± 0,5-1% [depending upon bulk density of product, constant product availability in the product tank (for liquids) proper maintainence] OVERALL DIMENSIONS , (W x L х H)950 x 1100 x 2900 mm WEIGHT~ 700 kg SALIENT FEATURES Length of film pulling is controlled by servomotor, which provides accurate and smooth pulling without jerks and losses Programmable logic controller (PLC) and color multilingual control touch screen (HMI) One-button start / stop of the machine

Request for a quote

NHM LIMITED

Ukraine

Production Speed: 4200 – 6000 pouches/hour Package Type: Pillow Pouch Filling range: 200-1000 ml. Photo eye registration unit – 2 pcs. Programmable Logic Controller (PLC) and Touch screen panel (HMI) Mitsubishi Thermal printer – 2 pcs. Filler – 2 pcs. Servomotor Mitsubishi – 2 pcs. Spare parts kit Terms of supply: 40-50 days Terms of start up: 5 – 7 working days Warranty: 12 months SALIENT FEATURES Length of film pulling is controlled by servomotor, which provides accurate and smooth pulling without jerks and losses Programmable logic controller (PLC) and color multilingual control touch screen (HMI) One-button start / stop of the machine Constant maintenance of temperature of heating elements during “pause” mode PLC automatically diagnoses and displays emergency alarms on the screen Parameter settings of the machine (recipes) for every combination of “film-product” can be stored in memory for easy changeover to another product or film type;

Request for a quote

NHM LIMITED

Ukraine

TECHNICAL DATAPARAMETER Speed, max.50 pouches/min. Filling volume, cm3100 – 1000 ml. (depending on filler) Type of packageready “”Doypack” pouch Packet width, max.200 mm Packet length, max.350 mm Electricals220 V, 50 Hz Power, kW1,5 Air consumption, l/min (0.6 Bar)460 Dimensions, mm2530x970x2190 Weight, kg850 WORKING PRINCIPLE Packaging machine grips empty “Doypack” pouch from a magazine, opens it, fills the product, prints date & seals the pouch. With the help of an orientator (optional) it can orientate and feed spouts to the sealing area and seal the spout vertically on to the pouch. Machine is equipped with parts for working with pouches of one width size. PRODUCTS TO BE PACKED: Food products: mayonnaise, condensed milk, jam, ketchup, tomato paste, sauces, tea, coffee, milk powder, rice, juices, cooking oil, etc. Non-food products: shampoo, liquid cleaning agents, fertilizers, cosmetic cream, window washer, toothpaste, washing powder, etc.

Request for a quote

PAK SISTEMI

Serbia

Vacuum packing machines for food industry and industrial use. We are one of exclusive dealers of Henkelman for Serbian and BIH market.

Request for a quote

OMG DENGE DIS TIC LTD.

Turkey

We have 5 models for shrink wrapping machines: 1) 90 pack/min overlap type, film only, double lane 2) 45 pack/min overlap type, film only 3) 20 pack/min sealing bar type, film only 4) 14 pack/min sealing bar type, film only

Request for a quoteResults for

Packing machines for packing - Import exportNumber of results

16 ProductsCompany type