- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal screws

Results for

Metal screws - Import export

EVER FASTENINGS LTD

Turkey

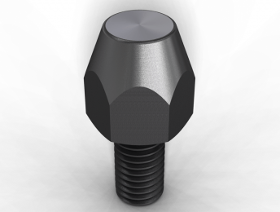

With trilobular body form and special thread design, EF-TITE screws can thread itself for metal components. It complies with DIN 7500

Request for a quote

ACTON S.A.

France

Hexagonal Nuts Metric Thread Fine Pitch (ECR HU Fine Pitch) Inox A4 - DIN 934 There is a variant in Inox A2 This nut can be combined with a DIN 933 metal screw or a DIN 931 metal screw and a medium type M flat washer NFE25513

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

During re-machining, a cutting tool is used to remove material from a workpiece in order to shape or surface it as required. We offer re-machining (turning, twisting) as wage work. The following machining operations we offer: Turn thin stem, pins and tips Screw punctures, approaches and undercuts Heads of screws / cold shaped parts machining process (turning) further machining operations are possible on request. Our curve-controlled automatic Audrema lathes offer you further possibilities of finishing cold-moulded parts. These automatic lathes are designed to achieve maximum precision and reproducibility at high throughputs. Short loading and unloading times permit economical production of medium-sized and large series.

Request for a quote

METFIX GROUP

Kazakhstan

Washer for roofing screws With EPDM rubber gasket, galvanized / has no official standard The washer for the roofing screw is equipped with an EPDM rubber gasket made of ethylene, propylene, diene, methylene. It is not used without a self-tapping screw. The metal part of the washer is coated with white zinc. When painting the roofing screw, the metal part of the washer surface is painted. Coating of the metal part: white zinc. Gasket material: neoprene or EPDM E - ethylene, P - propylene, D - diene, M - methylene. Attention! The thickness of the EPDM rubber gasket on the washer is 2.4-2.8 mm.

Request for a quote

METFIX GROUP

Kazakhstan

Roofing self-tapping screw for metal DIN-EN-ISO 15480 (old - DIN 7504-K) with an EPDM washer 2.4-2.8 mm thick Standard Head: hexagonal with a shoulder, , turnkey 8 (D-5.5) or 10 (D-6.3) mm, a marking mark in the form of the letter "X" is stamped on the cap

Request for a quote

COLORICIO.SRL

Romania

Round steel / Square steel, Flat steel , L cornier profile , IPE Steel and much more

Request for a quote

SYSKOMP GMBH - EMICO

Germany

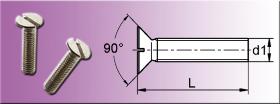

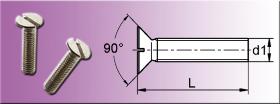

Countersunk screws - metal ~DIN 963 (~DIN EN ISO 2009) Material: stainless steel A2

Request for a quote

SYSKOMP GMBH - EMICO

Germany

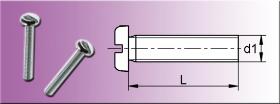

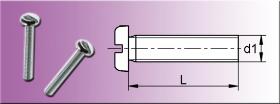

Pan head screws - metal ~DIN 85 (~DIN EN ISO 1580) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Countersunk screws - metal ~DIN 963 (~DIN EN ISO 2009) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

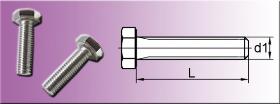

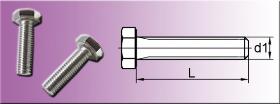

Hexagon head screws - metal ~DIN 933 (~DIN EN ISO 4017, threaded to head) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Hexagon head screws - metal ~DIN 933 (~DIN EN ISO 4017, threaded to head) Material: stainless steel A2

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Pan head screws - metal ~DIN 85 (~DIN EN ISO 1580) Material: stainless steel A2

Request for a quote

SYSKOMP GMBH - EMICO

Germany

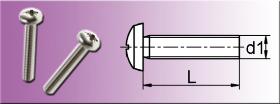

Lens head screws - metal, cross slot ~DIN 7985 (~DIN EN ISO 7045 - form H) Material: machining steel 4.8 zinc-plated

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ENBI PLASTICS & SILICONES BV

Netherlands

Creating an optimal bond between a metal plate and the silicone: that was the challenge Enbi Plastics was given by Océ Technologies, a major player in printing and copying equipment. They needed a new wiper assy; a part on the print head that prevents streaks on the paper. Because this part needs to be somewhat flexible, silicone needed to be added to a small, punched metal plate, to which screw thread is welded. This construction did not allow for a mechanical bond between the metal and silicone, which meant chemical bonding was the only option. Together with the client, the mould supplier, the silicone supplier and others, we did extensive research into the best way to achieve this bond. It showed that preparing the small metal plates was the key. After several tests, we discovered the optimal way to do this. A number of factors play a role: from how to clean and sand the plate to humidity, temperature and the time in between the steps of the process. Every detail counts!

Request for a quote

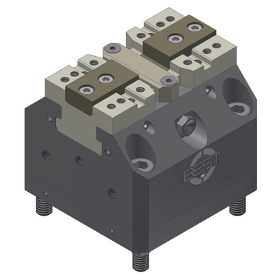

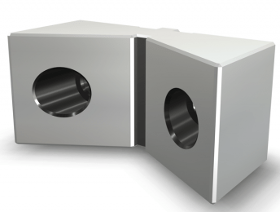

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Switch between jaws and faceplates in seconds Clamp more complex workpieces Clamp more components at a time Load faceplates outside the machine for better efficiency Faceplates form the base for a fixture to mount directly to the QwikLOK. They are ideal for complex workpieces that cannot be mounted in soft jaws and also allow smaller workpieces to be clamped in larger quantities. Combine a faceplate with simple workstops and clamps to buld a multi component fixture that can be loaded outside the machine. Add another identical faceplate and you have a manual pallet changing system to virtuallly eliminate loading time.

Request for a quote

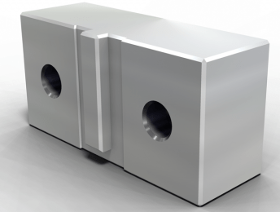

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Change jaws in seconds and complete a full setup in a few minutes Precise loction of jaws means your datum is preserved every time you remove the jaws. Once a job is setup, it stays setup. Machinable workholding means complex shaped workpieces are easy to grip Single station jaws can grip larger workpieces with just a quick jaw change Single Station Machinable Jaw Sets increase the flexibility of your system by eliminating the need to completely switch fixtures for jobs requiring greater holding capacity. Simply QwikChange the jaws and the set-up is ready in minutes. These jaws are compatible with 1030 Qwik-loks and 1030 Multi-Loks and are available in a range of sizes. All jaws are available as sets or individually.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Repetition Accuracy of 5 micron Extremely High Clamp Forces Low wear due to Nitrogen Hardened Surfaces Suitable for Internal or External Clamping BEST hydraulic centric vices are a no compromise solution to repeating and long running 4th and 5th axis workholding. BEST have focused on the production of high accuracy, high rigidity vices. These vices are suitable for both internal and external clamping. They offer very high clamping forces and repeatability of 0.005mm and a centring accuracy of 0.01mm. The Hydraulic vices also have the following options: Clamp Path Monitoring, Fixed Jaw, Central Lubrication System and Positive Air Pressure to prevent swarf ingress.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick Change Mechanism Hardened for Longevity Clamping Surface is Grooved to Avoid Marking Component Custom Sizes Available For clamping workpieces that must not be damaged. The clamping surface is grooved and not ribbed. This results in reducing the potential for marking components. The stepped jaw is hardened approx. 0.2 mm deep. The accuracy of the surface with respect to the serration is +/- 0.02 mm. For greater accuracy, the jaws must be ground in tension on the vice.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick Change Mechanism Hardened for Longevity Gripping Serration is 3mm deep to Reduce Waste Material Requires Low Clamping for during Machining, Reducing Deformation Gripper jaws can reduce the risk of the part being torn out under high machining forces. The penetrating tips produce a very high holding force even at low clamping force.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Aggressive machining operations while clamping on as little as 1.5mm Ideal for difficult applications or proto-type work Jaws to suit round or complex profiles as well as regular shapes Available for 6" and 8" vices Increase the functionality of your standard 150mm and 200mm vices. This combo kit is a simple bolt on system that will allow you to perform aggressive machining operations on Square, round or complex parts while clamping on as little as 1.5mm. This set includes a set of TalonGrip jaws (Sets includes 4 TalonGrips, 1 stop and M5 screws) and a set of VersaGrip jaws (Set includes 4 VersaGrip with M5 Screws).

Request for a quote

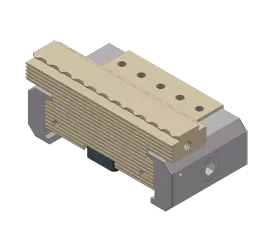

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Easy machining of round workpieces High precision and high clamping force Wide range of accessories for flexibility Maximise your machining envelope Fixed v-jaws for the SVF range of flexible vices. There are bolt-on hard v-jaws to fit all types of fixed jaw in the SVF range including wedge type and non-wedge type. These v-jaws have a centre key for accurate positioning.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Easy machining of irregular workpieces High precision and high clamping force Wide range of accessories for flexibility Maximise your machining envelope Fixed soft jaws for the SVF range of flexible vices. There are bolt-on soft jaws to fit all types of fixed jaw in the SVF range including wedge type and non-wedge type. These soft jaws have a centre key for accurate repositioning and do not require re-skimming every time they are used.

Request for a quote

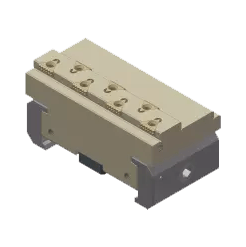

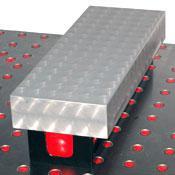

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Maximise your machining envelope High precision and high clamping force Wide range of accessories for flexibility Clamp single large or multiple small workpieces Clamps to suit OK-Vise Multi-Rail. Multi-Rail can accommodate OK-Vise clamps, stops, parallels and other accessories to clamp multiple components and maximise your milling work area. All the clamping and location elements on the rail can be positioned according to the size and shape of the workpieces to swiftly adapt from clamping multiple small workpieces to clamping single large workpieces. These clamps are available in a range of styles and applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Maximise your machining envelope High precision and high clamping force Wide range of accessories for flexibility Clamp single large or multiple small workpieces Workstops to suit OK-Vise Multi-Rail. Multi-Rail can accommodate OK-Vise clamps, stops, parallels and other accessories to clamp multiple components and maximise your milling work area. All the clamping and location elements on the rail can be positioned according to the size and shape of the workpieces to swiftly adapt from clamping multiple small workpieces to clamping single large workpieces. These stops are available in a range of styles and applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Switch between jaws and faceplates in seconds Clamp more complex workpieces Clamp more components at a time Load faceplates outside the machine for better efficiency Faceplates form the base for a fixture to mount directly to the QwikLOK. They are ideal for complex workpieces that cannot be mounted in soft jaws and also allow smaller workpieces to be clamped in larger quantities. Combine a faceplate with simple workstops and clamps to buld a multi component fixture that can be loaded outside the machine. Add another identical faceplate and you have a manual pallet changing system to virtuallly eliminate loading time.

Request for a quoteResults for

Metal screws - Import exportNumber of results

43 ProductsCountries

Company type