- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- manufacture of springs

Results for

Manufacture of springs - Import export

TEMAS GROUP EXPORT PARTNERS

Turkey

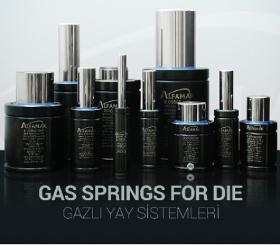

ALFAMAK is one of Turkey's leading gas spring manufacturers. Established in 2003, our company has been operating in the industry for 19 years and has gained a reputation for success. Gas spring is a new technology which comes instead of standard steel or polyurethane springs. A gas spring has a container of compressed Nitrogen gas with Piston Rod , Bush, Rod Rings, Valve etc. The Gas Springs are used in Cold Stamping industry to form, cut and fix the sheet metal inside the die. Many auxiliary materials are used for different purposes in the gas spring. Rod wiper, rod guide and rod seal are used on the inner surface of the bush. The purpose of the rod wiper is to prevent the oil and chips in the die from entering the gas spring. The rod guide is used to carry the load in case of axial force on the rod during use. The most important auxiliary material for sealing is rod/piston seal. It directly affects the performance of the product by keeping the gas in the gas spring.

Request for a quote

VINCO

Spain

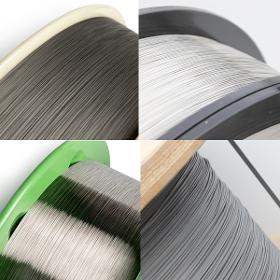

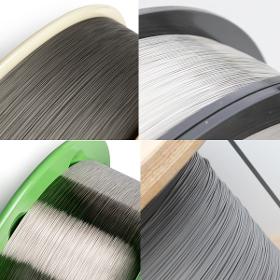

composition : X5CrNiMo17-12-2 According to EN 10270-4316 and AISI 316 The surface of the stainless steel wire must be smooth and, insofar as is possible, free of scratches, pitting and other surface defects that may make the wire unusable. The alternating torsion test is one method that makes it possible to detect surface discontinuities. If the wire is to be used for manufacturing springs that are used for high stresses, the special surface quality requirements and tests can be agreed on the customer's instruction when the quote is requested or the order is placed. SURFACE QUALITY EN 10088-3 Minor surface irregularities that are inherent to the manufacturing process are permitted. When necessary, it is possible to agree on more specific surface quality requirements when placing the order, based on the EN 10221 Standard.

Request for a quote

VINCO

Spain

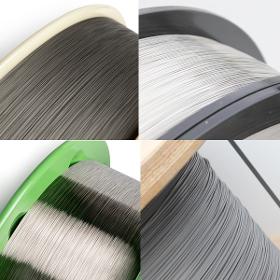

composition : X1NiCrMoCu25-20-5 According to EN 10270-7904L and AISI 904L The surface of the stainless steel wire must be smooth and, insofar as is possible, free of scratches, pitting and other surface defects that may make the wire unusable. The alternating torsion test is one method that makes it possible to detect surface discontinuities. If the wire is to be used for manufacturing springs that are used for high stresses, the special surface quality requirements and tests can be agreed on the customer's instruction when the quote is requested or the order is placed. SURFACE QUALITY EN 10088-3 Minor surface irregularities that are inherent to the manufacturing process are permitted. When necessary, it is possible to agree on more specific surface quality requirements when placing the order, based on the EN 10221 Standard.

Request for a quote

VINCO

Spain

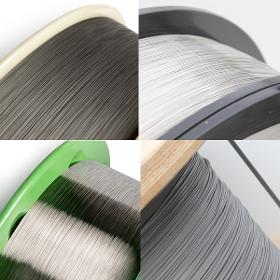

composition : X5CrNi18-10 (NS / HS) According to EN 10270-6304 and AISI 304 The surface of the stainless steel wire must be smooth and, insofar as is possible, free of scratches, pitting and other surface defects that may make the wire unusable. The alternating torsion test is one method that makes it possible to detect surface discontinuities. If the wire is to be used for manufacturing springs that are used for high stresses, the special surface quality requirements and tests can be agreed on the customer's instruction when the quote is requested or the order is placed. SURFACE QUALITY EN 10088-3 Minor surface irregularities that are inherent to the manufacturing process are permitted. When necessary, it is possible to agree on more specific surface quality requirements when placing the order, based on the EN 10221 Standard.

Request for a quote

VINCO

Spain

composition : X7CrNiAl17-7 According to EN 10270-5631 and AISI 631 The surface of the stainless steel wire must be smooth and, insofar as is possible, free of scratches, pitting and other surface defects that may make the wire unusable. The alternating torsion test is one method that makes it possible to detect surface discontinuities. If the wire is to be used for manufacturing springs that are used for high stresses, the special surface quality requirements and tests can be agreed on the customer's instruction when the quote is requested or the order is placed. SURFACE QUALITY EN 10088-3 Minor surface irregularities that are inherent to the manufacturing process are permitted. When necessary, it is possible to agree on more specific surface quality requirements when placing the order, based on the EN 10221 Standard.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KGA ENCLOSURES LTD

United Kingdom

• Professional phono line sockets manufactured from turned brass, with spring cable strain relief. • Suitable applications include: • Recording equipment • Test instrumentation • Audiophile equipment • Amplifiers • Interconnect cable assemblies

Request for a quote

FAIRON BEARINGS INTERNATIONAL

Belgium

Mubea is an international synonym for spring technology of the highest standard. Our disc springs comply with the highest worldwide quality standards. Our products are manufactured in Daaden, Germany - combining extensive know-how, modern quality control and decades of experience. Mubea has specialised in the production of quality disc springs for more than 40 years. Because of their versatility, disc springs are used in a large variety of industrial applications, ranging from safety valve systems placed 3000 m below sea level to satellites in outer space. Additionally, Mubea also excels in the production of related products, such as complex precision stamped parts. Disc springs in compliance with DIN 2093, as well as our own internal standards, are in stock on a permanent bases. Mubea manufactures disc springs with an outside diameter up to 800 mm, as well as internally and externally slotted disc springs, and wave springs. All products are manufactured in-house, beginning with the p

Request for a quote

FAIRON BEARINGS INTERNATIONAL

Belgium

Mubea is an international synonym for spring technology of the highest standard. Our disc springs comply with the highest worldwide quality standards. Our products are manufactured in Daaden, Germany - combining extensive know-how, modern quality control and decades of experience. Mubea has specialised in the production of quality disc springs for more than 40 years. Because of their versatility, disc springs are used in a large variety of industrial applications, ranging from safety valve systems placed 3000 m below sea level to satellites in outer space. Additionally, Mubea also excels in the production of related products, such as complex precision stamped parts. Disc springs in compliance with DIN 2093, as well as our own internal standards, are in stock on a permanent bases. Mubea manufactures disc springs with an outside diameter up to 800 mm, as well as internally and externally slotted disc springs, and wave springs. All products are manufactured in-house, beginning with the p

Request for a quote

FAIRON BEARINGS INTERNATIONAL

Belgium

Mubea is an international synonym for spring technology of the highest standard. Our disc springs comply with the highest worldwide quality standards. Our products are manufactured in Daaden, Germany - combining extensive know-how, modern quality control and decades of experience. Mubea has specialised in the production of quality disc springs for more than 40 years. Because of their versatility, disc springs are used in a large variety of industrial applications, ranging from safety valve systems placed 3000 m below sea level to satellites in outer space. Additionally, Mubea also excels in the production of related products, such as complex precision stamped parts. Disc springs in compliance with DIN 2093, as well as our own internal standards, are in stock on a permanent bases. Mubea manufactures disc springs with an outside diameter up to 800 mm, as well as internally and externally slotted disc springs, and wave springs. All products are manufactured in-house, beginning with the p

Request for a quote

FAIRON BEARINGS INTERNATIONAL

Belgium

Mubea is an international synonym for spring technology of the highest standard. Our disc springs comply with the highest worldwide quality standards. Our products are manufactured in Daaden, Germany - combining extensive know-how, modern quality control and decades of experience. Mubea has specialised in the production of quality disc springs for more than 40 years. Because of their versatility, disc springs are used in a large variety of industrial applications, ranging from safety valve systems placed 3000 m below sea level to satellites in outer space. Additionally, Mubea also excels in the production of related products, such as complex precision stamped parts. Disc springs in compliance with DIN 2093, as well as our own internal standards, are in stock on a permanent bases. Mubea manufactures disc springs with an outside diameter up to 800 mm, as well as internally and externally slotted disc springs, and wave springs. All products are manufactured in-house, beginning with the p

Request for a quoteResults for

Manufacture of springs - Import exportNumber of results

11 ProductsCountries

Company type