- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining center

Results for

Machining center - Import export

APD MAQMASTER

Spain

The Ermes Machining Center is a high-quality tool that will allow you to carry out machining work with exceptional precision and efficiency. Its compact and robust design makes it ideal for mechanical workshops of any size. Ermes' high-speed, high-precision numerical control system will allow you to make complex parts with ease. In addition, its wide range of functions will allow you to customize the machining process according to your specific needs. With Ermes, you can save time and improve the quality of your machining products. The Ermes Machining Center also has an integrated cooling system that improves the precision of cuts and increases the life of the machining tools. In addition, its intuitive and easy-to-use interface will allow you to quickly configure tools and switch between them without problems.

Request for a quote

APD MAQMASTER

Spain

Developed to perform cutting, surface treatment and milling operations on wide aluminum and PVC profiles. It is designed to achieve greater efficiency in the shortest time with its units that can operate independently of each other

Request for a quote

APD MAQMASTER

Spain

Compact machining and milling center with copying function, on the 3 surfaces of aluminum and plastic profiles, with parametric program templates, developed to perform operations such as lock, handle, hinge, latch slot and opening processes. 10” touch screen Easy to program user interface Easy profile positioning with gauge and laser marking Spindle motors that operate independently on 3 different surfaces

Request for a quote

APD MAQMASTER

Spain

The GARNET ECO PLUS Machining Center is the perfect solution for your machining needs. With its robust and high-quality design, this equipment will allow you to obtain the best results in your production processes. Its state-of-the-art computer numerical control (CNC) system guarantees maximum precision in the machining of your parts, which translates into a significant improvement in the quality of your products. The GARNET ECO PLUS Machining Center also stands out for its ease of use. Thanks to its intuitive interface, you can program your machining processes simply and quickly. In addition, its compact and ergonomic design will allow you to save space in your workshop.

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing : 2018 CNC control : HEIDENHAIN iTNC 640 Number of simultaneous axes : 5 Stroke X axis : 2000 [mm] Stroke Y axis : 600 [mm] Stroke Z axis : 550 [mm] Feed rate on X, Y and Z axes : 20000 [mm/min] Traversing feeds X, Y and Z axes : 40000 [mm/min] Axes acceleration : 2.5 [mm/sec²] Min. distance spindle nose / table : 30 [mm] Table length : 1250 [mm] Table width : 800 [mm] Max. load on table : 500 [Kg] Rotary tilting table surface : 600 x 600 [mm] Stroke C axis : table revolution : 360 [°] Max. speed C axis : 25 [rpm] B axis swivelling stroke : -110 / +110 [°] Spindle type : ISO 40 Max. spindle speed : 15000 [rpm] Spindle power : 17 [kW] Tool changer magazin number of stations : 80 Max. tool length : 300 [mm] Max. weight of single tool : 7 [Kg] Total max. weight in tool changer magazin : 400 [Kg] Total power required : 57 [kVA] Supply voltage : 400 [V] Number of hours under power : 17840 [h] Weight : 15000 Kg

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 2020 CNC control : HEIDENHAIN TNC 640 Number of simultaneous axes : 5 Stroke X axis : 650 mm Stroke Y axis : 850 mm Stroke Z axis : 500 mm Traversing feeds X, Y and Z axes : 36000 mm/min X axis ball screw, Ø x pitch : 40 x 12 mm Y axis ball screw, Ø x pitch : 40 x 12 mm Z axis ball screw, Ø x pitch : 40 x 12 mm Angular A axis stroke : +/- 120 ° Angular C axis stroke : 360 ° Min. distance spindle nose / table : 150 mm Max. distance spindle nose / table : 650 mm Spindle type : HSK-A 63 Max. spindle speed : 20000 rpm Tool changer magazin number of stations : 60 Max. tool length : 300 mm Max. weight of single tool : 8 Kg Total max. weight in tool changer magazine : 480 Kg Max. tool diameter : 125 mm Total power required : 60 kVA Number of hours under power : 5683 h Number of running hours : 3183 h Machine weight : 12000 Kg Machine dimensions : 3390 x 3940 x 2970 mm With equipment

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer Format 4 Model Profit H200 Year 2017 Condition Used X-axis travel 3300 mm Y-axis travel 1280 mm Z-axis travel 250 mm Workpieces 100 mm Power motor 12 - 15 kW Spindle speed 24000 rpm N° tool 12

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer Biesse Model Rover 24 Year 2001 Condition Used Made in Italy Control unit ROVER NC 500 X-Axis travel 3436 mm Y-Axis travel 1700 mm Z-Axis travel 250 mm Table length 3060 mm Table width 1300 mm Spindle taper ISO 30 Motor power 7.5 kW Vacuum pump 100 m3/h Axes speed X/Y/Z 100/100/30 m/min Rotation speed max 18000 rpm

Request for a quote

APD MAQMASTER

Spain

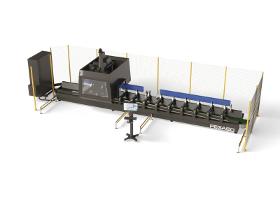

This cutting and machining center has an automatic feeding table for 10 profiles, which allows maximum efficiency and effectiveness in the processing of cutting lists, saving time and maximizing production. The cutting unit has a 550 mm diameter disc which works at any angle between 30º and 150º, offering a wide range of positions for the cutting disc. Uses: cutting, milling, drilling the water drainage channel and working with PVC and aluminum profiles alike. Designed to achieve the greatest efficiency in less time. Capable of performing 15 different operations with 13 fan-cooled spindle motors, a triple arm opening motor and a disc motor. It offers unlimited processing possibilities on all 4 sides of the profile. PRODUCT DETAILS AXLE DISTANCE X axis (longitudinal) min 270 mm / max 3000 mm. Y axis (Horizontal) min 30 mm / max 150 mm. Z axis (Vestical) min 30 mm / max 180 mm. SR axis (Drive Robot) min 1200 mm / max 6500 mm.

Request for a quote

APD MAQMASTER

Spain

GARNET ECO offers its user a flexible work area thanks to the manually moved jaws that can be adjusted in height according to the profile. Users also appreciated the high processing capacity (200 mm x 180 mm) when performing these operations. Thanks to the built-in 5-tool manual change station, you save time when performing different operations. Thanks to the automatic tool tip cooling system in the spindle motor, it allows you to create a clean and precise machining surface and extends the life of the tool tip. The GARNET ECO machining center is an essential tool in any machining workshop that seeks maximum efficiency and productivity in its daily work. Thanks to its compact and versatile design, this equipment is capable of performing multiple machining operations with high precision and quality.

Request for a quote

APD MAQMASTER

Spain

The Ares 3-axis machining center is a high-quality tool that will allow you to carry out machining work with exceptional precision and efficiency. Its compact and robust design makes it ideal for mechanical workshops of any size. Ares' high-speed, high-precision numerical control system will allow you to make complex parts with ease. In addition, its wide range of functions will allow you to customize the machining process according to your specific needs. With Ares, you can save time and improve the quality of your machining products. The Ares 3-axis machining center also has an integrated cooling system that improves the precision of the cuts and increases the useful life of the machining tools. In addition, its intuitive and easy-to-use interface will allow you to quickly configure tools and switch between them without problems. Characteristics: High speed and precision CNC numerical control system

Request for a quote

APD MAQMASTER

Spain

Available in versions of 4, 7, 9, 11 and 13 meters also with double clamping and with supports for angular heads suitable for specific processes. Your basic tool changer includes 15 positions, but can be expanded to 30 upon request. The 300 x 640 mm machining section allows a wide range of operations to meet any need. Among its most notable features, PEGASO includes: a 400mm blade and a tool blade that can be combined with the 500mm accessory blade unit. PEGASO is perfect for facades, building profiles, automotive industry, lighting technology, railway sector and all light industries in general. The Pegaso machining center is a high-power, high-precision machine designed for CNC machining parts in various materials, such as metal, plastic and wood.

Request for a quote

APD MAQMASTER

Spain

Available in 4, 9 and 11 meter versions, it is especially suitable for machining steel and aluminum. It is equipped with powerful 20, 24 or 30 kW electrospindles, both asynchronous and synchronous, which guarantee maximum efficiency thanks to the liquid cooling system. The machine can be placed in the medium-heavy industrial sector. With this machining center, Italmac places itself among the highest-performance machining workshops. THOR is a rigid center with a gantry structure with slack recovery and hydraulic closing jaws, which guarantee a secure grip. It is also equipped with: a tilting head that, thanks to its hydraulic brakes, guarantees rigidity during machining , a tool changer with 15 to 30 positions, an automatic tool probe and a metal chip evacuation belt.

Request for a quote

APD MAQMASTER

Spain

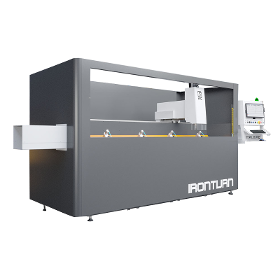

IRONTURN is completed with a 5-position automatic central magazine, 4 robust jaws, a double lubrication system (micro-drip + water) and a removable drain tray to facilitate the disposal of remains. Thanks to its ease of use and compactness, IRONTURN is perfect for small carpentry and the window and door frame sector.

Request for a quote

APD MAQMASTER

Spain

1. Advanced CNC machining center with servo turning table and 4 servo clamps. 2. Suitable for processing aluminum profiles (up to 3mm thick) and steel profiles (up to 2mm thick) with super fast speed (5m/min) and efficiency thanks to laser technology. High pressure air compressor (1.6Mpa) and cooling station are included. 3. The machine completes milling, drilling, chamfering, slotting and other multifunctional precisely in one time. 4. The work table will be positioned from +90° to -90° variable angle. 5. Automatic lifting safety cover ensures operator safety. 6. Automatic tool change: standard equipped with 6-position hidden tool magazine, standard equipped with 3 tool holders. 7. Operation in Windows environment industrial PC with monitor. Friendly machine interface with user-friendly operation. 8. In line with ERP software, it can perform code scanning and automatic processing.

Request for a quote

APD MAQMASTER

Spain

It can be customized according to customer needs. Suitable for industrial and automotive applications. Load capacity of 300 x 2600 mm combined with a dedicated center for multiple parts. It has a 600 mm gluing blade with a 4 kW motor. Powerful 13 Kw electrospindle

Request for a quote

APD MAQMASTER

Spain

ULISSE is the ideal machine for an industrial sector with increasing demands. A 4-axis CNC that includes a large work area, the largest available in this sector, with a size of 700 x 300 mm. Available in standard 4, 7 and 9 meter versions, ULISSE can be extended up to 11 and 13.5 meters in length. In all lengths it can be made in the version with or without cabin with single or double work area. Special versions of this machine have been created for machining fiberglass, steel and all materials that can be machined with end mills. The tools are cooled with emulsified oil by means of pumps placed on the mobile carriage, but on request it can also be done by means of a water-oil group with a recycling pump. The Ulisse machining center is an industrial machine that offers high efficiency and precision. It is designed for CNC machining parts in a wide variety of materials, such as metal, plastic and wood.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Steel Machinery Parts manufactured by CNC machining center

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

brass machine parts Mechanical Turning & Milling on the CNC machining center

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Aluminium Parts manufactured by CNC Machining Center Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

GLOMACHT BV

Netherlands

Used Woodworking Machinery Glomacht has an variety of woodworking machinery that will help you perform workshop.Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything. For more info, please contact us: contact@glomacht.com Buy / Sell your machinery with us! SHARE YOUR USED POWER!

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything. For more info, please contact us: contact@glomacht.com Buy / Sell your machinery with us! SHARE YOUR USED POWER! Woodworking - CNC Machining Centers

Request for a quote

GLOMACHT BV

Netherlands

Used Machining Centers Used CNC Machining Centers I Buy & Sell Used Machinery.

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything. For more info, please contact us: contact@glomacht.com Buy / Sell your machinery with us! SHARE YOUR USED POWER! Woodworking - CNC Machining centers Used SCM CNC Machining centers ACCORD 30 FX in good condition made in Italy from 2012. 5 AXIS and with a power of 20,000 rpm.

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything. For more info, please contact us: contact@glomacht.com Buy / Sell your machinery with us! SHARE YOUR USED POWER!

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything. For more info, please contact us: contact@glomacht.com Buy / Sell your machinery with us! SHARE YOUR USED POWER!

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything.CNC Machining centers - Year: 2011 CNC controlled gantry milling machine with flat table and drill unit.

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything.NC Machining Centers - Year: 2002 Machine including Volkswagen ladder software, projection laser and cutting tools.

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything.CNC Machining Centre - Window production CNC controlled machine with industrial PC Nexus touch screen TFT color display Network card (10 / 100Magabit / TCP / IP) (modem) Data transfer via USB interface or online Electrical data: 4-pole cable connection, connection load 84 kW, Electric current 176.4 A, pre-fuse 200A Required dust extraction capacity: 239m³ / min Required air pressure: 8 bar nominal

Request for a quoteResults for

Machining center - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Laser - cutting and welding machines (16)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (14)

- Milling - machine tools (2)

- Mechanical engineering - custom work (2)

- Paper - Printing - Machines & Equipment (2)

- Cutting, plastics - machinery (1)

- Engineering - industrial contractors (1)