- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine belts

Results for

Machine belts - Import export

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 20 form, fill and seal machine enables the production of bags made of polyethylene film from a flat film roll. The film can be neutral or coloured, with continuous printing or centred printing with print mark. The design of the machine and the low loading height allow ergonomic adaptation to a manual feeding station or easy connection to a feeding unit, such as an automatic counter, an automatic weighing system, an automatic assembly machine, an injection moulding machine, a conveyor belt or similar.

Request for a quote

TECHNIC MACHINES

Turkey

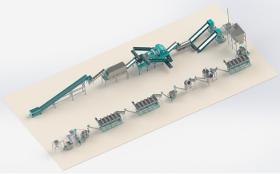

Our PU, PIR and PUF sandwich panel production machines have different capacity and production thickness from 30 mm to 200 mm and also sandwich panel making machine speed from 6 meters/minute to 16 meters/minute with 50 mm sandwich panel thickness production. Our sandwich panel machine lines are the optimum solution in the market with quality and performance matching parameters. Sandwich Panel Production Line Units Roll Decoiler Machine Feeding Unit Film Coating Unit Roll Forming Machine Rolling Conveyor Unit Pre-Heating Foaming Machine Double Belt Pressing Machine Rolling Conveyer Fly Cutting Unit Runout Table Automatic Vacuum Stacker Automatic Packaging Machine Metal raw material can be changed on sandwich panel machines, as aluminium, metal sheet, pre-painted metal sheets etc.

Request for a quote

TECHNIC MACHINES

Turkey

Our PET bottle recycle machine line is designed to give great recycling solution for PET bottle recycle process. We provide different solutions according to our customers PET bottle recycle machine demand, such as different capacity, dirtiness level, hot washing or cold washing system or etc. So we design our PET bottle recycle machine according to our customer's market requirements. Our PET bottle washing line can be designed for high level dirty PET bottles, with or without bales, Hot-Wash or Cold-Wash and etc. PET Bottles Recylce Machine Line Main Units, – Conveyor – Bale Opening Machine – Helezon – Cap and Label Remover – Sorting Belt – Drum Tromel – Conveyor Belt – Crusher Machine – Screw Loaders – Hot Washing Unit – Friction Washer – Flotation Tanks – Drying Units – Big Bag Filling Unit Just contact with us for your PET bottle recycling machine research, we will provide the optimum solution.

Request for a quote

VIRMER

Netherlands

Designed for cutting and engraving of non-metallic materials. This machine will be a solid foundation for small and medium-sized production, as well as a great addition to a large manufacturing company. Engraving : Wood, plywood, cardboard, paper, plastic, plexiglass (acrylic), leather, fabric, fur, PET, MDF, glass, stone etc. Cutting: Wood, plywood, cardboard, paper, plastic, plexiglass (acrylic), leather, fabric, fur, PET, MDF, rubber, paronite, foam rubber All Wattsan co2 laser machines use only a 3M belt, it is not subject neither to overheating nor to stretching. Work area = 900 x 600 mm Tube power = 80-90 W Max engraving speed = 700 mm Dimensions = 1030 mm * 1490 mm * 670 mm + 315 mm (if on its wheels) Net Weight = 230kg

Request for a quote

MPT DOSING GMBH

Germany

/ Static Inline Mixers Dynamic Inline Mixers Dynamic inline mixers have, contrary to static mixers, a driving motor with variable agitator speed, providing for the required mixing energy. The main field of application for dynamic inline mixers is the intensive and adjustable mixture of polymer flocculation agents with the sludge to be dewatered on dewatering machines like (belt) filter presses. Using dynamic inline mixers the active ingredient contained in the polymer is dispersed evenly in the sludge to be dewatered, resulting in a noticeable improvement of the dewatering characteristics and a considerable reduction of the required flocculation agent. A suboptimal mixture of the flocculation agents is often compensated by a considerable increase of the dosed quantity. In many applications the flocculation agent is dosed in a stronger dilution to improve the miscibility. However, this means that water which actually should be detracted from the system is now added to the system. I

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SPARX MACHINE TOOLS

United Kingdom

The Kuhlmeyer ZBS Twin Belt Grinding Machine is built for the roughing and finishing on welded edges, corners and surfaces on flat and mid-size workpieces out of steel, stainless steel, and aluminium, i.e. doors, frames, cabinets, housings, hoods, furniture parts, frame parts in automotive and aircraft – manufacturing, round bins, cylinders, heaters etc.

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

WF 9221-76 – Single needle extra heavy duty walking foot sewing machine with large working space (76 cm) and extra large rotating hook. Specially designed for sewing tentcloth, sailcloth, heavy upholstery materials and belts. Machine is standard equipped with pneumatic back tack and presser foot lift. WF 9221-2-76 – Double needle extra heavy duty walking foot sewing machine with large working space (76 cm) and extra large rotating hooks. Specially designed for sewing tentcloth, sailcloth, heavy upholstery materials and belts. Machine is standard equipped with pneumatic back tack and presser foot lift. Standard needle gauge 18 mm. WF 9221-76 – Single needle extra heavy duty walking foot sewing machine with large working space (76 cm) and extra large rotating hook. Specially designed for sewing tentcloth, sailcloth, heavy upholstery materials and belts. Machine is standard equipped with pneumatic back tack and presser foot lift. WF 9221-2-76 – Double needle extra heavy duty...

Request for a quoteResults for

Machine belts - Import exportNumber of results

8 ProductsCompany type